Mesh Belt Dryer Machine

Brand: KAIBANG

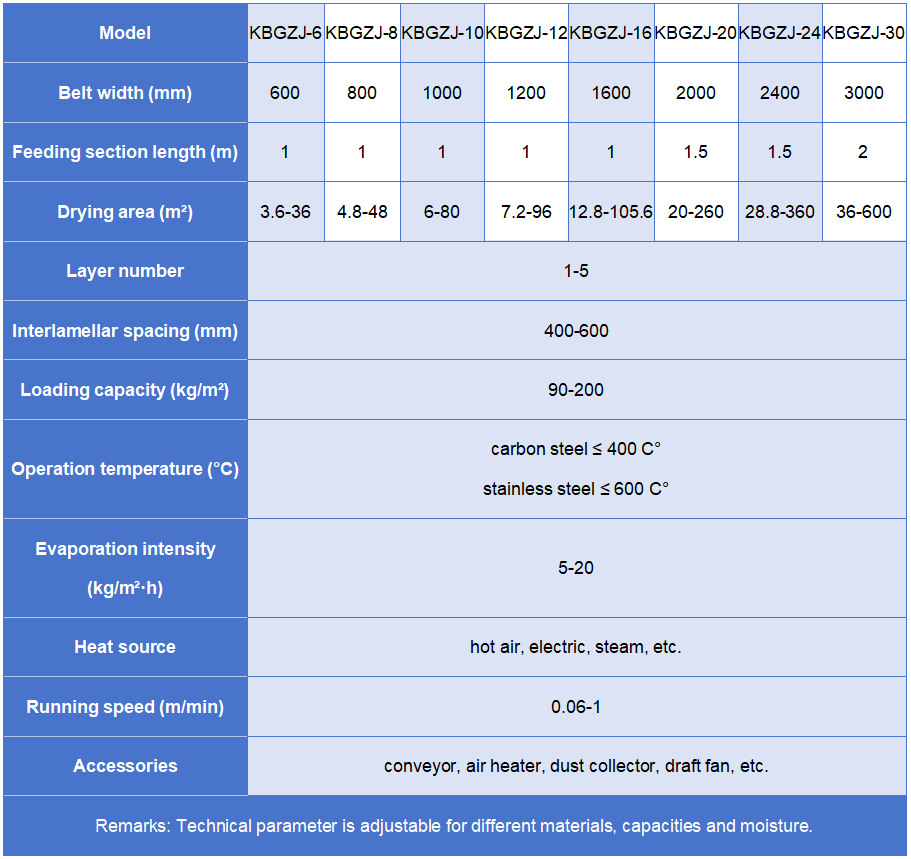

Capacity: 60-300Kg/h (Production capacity is affected by factors such as material type, moisture, density, etc.)

Drying Length: 6-11.5 m

Working Temperature: 50-140℃

Steam Pressure: 0.2-0.8 MPa

Power: 11.4-11.7 kW

Procession Material: Various briquettes, such as coal briquettes, mineral powder briquettes, iron powder briquettes, and fluorite powder briquettes.

Mesh belt dryer is a batch type, continuously working drying equipment. Mesh belt dryer is usually used to dry various briquettes, such as coal briquette, mineral powder briquette, iron powder briquette, fluorite powder briquette. Moisture content after drying could reach 5% below (moisture content is adjustable by the control system).It is widely used as essential equipment in briquette production lines. Additionally, our stainless steel mesh belt dryer can be utilized to dry materials such as cassava chips, fruits, vegetables, pharmaceuticals, and food products. The mesh belt dryer features high efficiency, large output, strong evaporation intensity, and standardized production. We can add sections based on production capacity requirements. This dryer is particularly efficient for materials requiring low moisture content. Customized services are available upon customer requests. The main heating methods include electric heating, steam heating, and hot air heating. Materials processed by the mesh belt dryer are easy to store and transport. As an energy-saving and environmentally friendly device, the mesh belt dryer creates significant economic and social benefits.

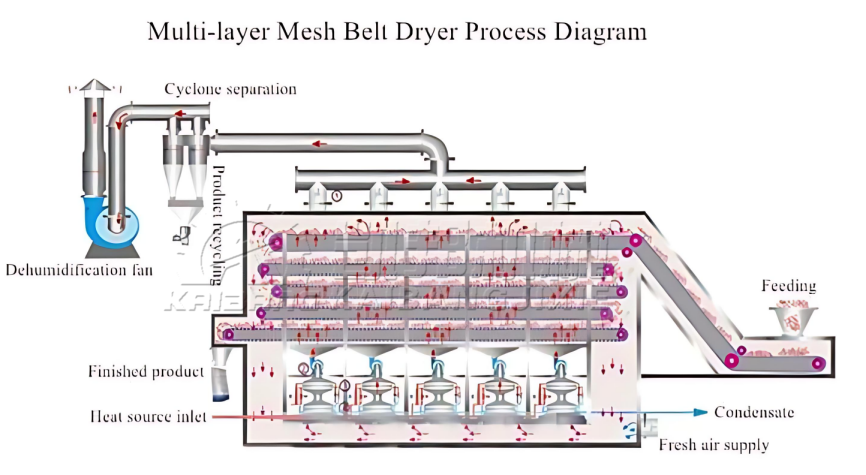

The mesh belt dryer adopts a modular design, primarily composed of the following core components: machine head, drying section, tail section, high-strength mesh belt, precision transmission system, intelligent feeding and material distribution system, air inlet duct, air outlet duct, high-efficiency fan, heat source equipment, and conveying equipment. The mesh belt utilizes 12-60 mesh high-quality steel wire mesh to ensure stable and reliable material conveyance.

In charcoal briquette drying applications, materials are evenly distributed on the conveyor belt and pass through drying channels composed of multiple independent heating units. Each heating unit is equipped with an advanced air heating circulation system and professional dehumidification devices (1 to multiple sets per channel). As the mesh belt operates, hot air uniformly penetrates the material layer, while water vapor is efficiently discharged through dehumidification vents, achieving uniform material drying. The equipment features a modular cabinet design with flexible standard section combinations. Multi-layer configurations (such as two-chamber three-layer or two-chamber five-layer) can be selected according to site conditions. The equipment length is adjustable from 6 to 40 meters, with an effective working width of 0.6 to 3.0 meters, fully meeting diverse production needs.

Materials enter through the machine head and slowly pass through the dryer for drying. The mesh belt's linear speed depends on the material type and moisture content. Airflow utilizes negative pressure and multi-hole air supply to ensure effective drying area and uniform wind speed distribution, enhancing drying efficiency. To achieve optimal drying results and appropriate output, the material moisture content, mesh belt linear speed, airflow volume, and air temperature must be properly and organically combined.

Heat Source

The main heating methods include electric heating, steam heating, and hot air heating.

Layers

Available in single-layer or multi-layer configurations, customizable based on demand; length can also be customized.

Details show

Mesh belt dryer is mainly used for drying finished briquette to meet a low moisture for transportation or using, also it has other wild usages for all kinds of material.

Conveyor mesh belt dryer is a commonly used continuous drying equipment, which can be widely used in chemical, building materials, food, medicine, electronics and other industries, especially suitable for drying sheet, strip and granular materials with good ventilation. Paste-like materials such as filter cakes can also be dried after being formed by a granulator or an extruder.

The mesh belt dryer integrates high efficiency, energy saving, and multifunctionality, featuring the following prominent characteristics and advantages:

Cost-Effective: With low equipment investment, fast drying speed, and high evaporation intensity, it enables high-efficiency, high-output production while ensuring stable product quality. Adopting a standardized production mode allows flexible capacity expansion based on demand.

Precise Control: By adjusting airflow, heating temperature, material retention time, and feeding speed, it achieves optimal control of the drying process to ensure the best drying results. The unique air distribution device ensures uniform hot air distribution, guaranteeing consistent product quality.

Energy-Saving and Environmentally Friendly: Utilizing air recycling technology, most hot air can be recycled, significantly reducing energy consumption. It offers flexible heat source options, supporting steam, thermal oil, gas furnace, and other heating methods.

Multifunctional Applicability: The mesh belt dryer provides versatile applications. Not only suitable for continuous drying of coal balls (the larger the equipment size, the stronger the drying capacity), it can also process regular or irregular block/strip materials such as specially-shaped coal blocks, mineral powder balls, aquatic products, etc., making it particularly suitable for assembly line operations.

Durable and Reliable: With few wearing parts and a sturdy structure, the equipment ensures long-lasting durability. The high-strength mesh design of the belt guarantees stable material conveyance. It also supports the configuration of a mesh belt washing system and material cooling system to meet diverse production needs.

Flexible Configuration: The equipment can be integrated with other production equipment or operate independently, adapting to different production scenarios. Additionally, special functions can be customized based on customer requirements to further enhance production efficiency.

<Note: With continuous technological upgrades, all parameters are provided for reference only. In case of any modifications, please refer to the actual product for accuracy.>

Henan Kaibang Machinery Manufacturing Co., Ltd. mainly produces: crushing equipment, drying equipment, forming equipment, pyrolysis reactor equipment, environmental protection equipment, and other complete production line equipment. The company's equipment production, casting and forming, mechanical processing, physical and chemical treatment, to assembly into machines, is fully tracked and inspected by quality testing engineers throughout the process to ensure that users receive high-quality, reliable equipment.

The company has been working hard to build the Kaibang brand for decades, always pursuing excellence, with high-quality staff, strict quality assurance system and perfect after-sales service. We warmly welcome domestic and overseas customers to visit our company for on-site inspection and guidance.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: info@kaibangmachinery.com

Phone: 15638129993

E-mail: +86 15638129993

Whatsapp:86 15638129993

Add: 800 meters east of the intersection of Chuangye Avenue and E23 in Gongyi Industrial Agglomeration Zone, Zhengzhou City, Henan Province, north of the road