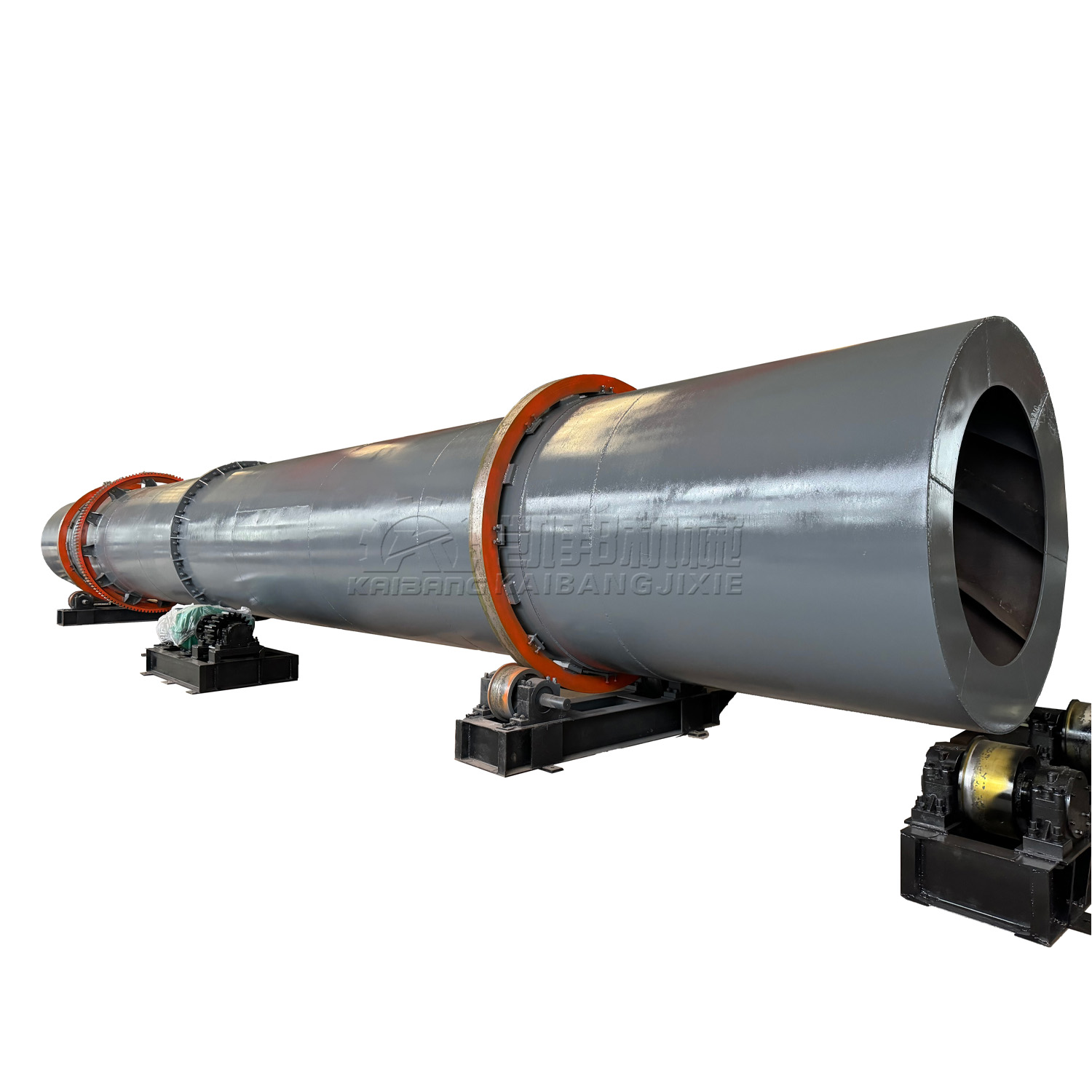

Air-Flow Dryer Machine

Brand: KAIBANG

Capacity: 500-1000kg/h (Production capacity is affected by factors such as material type, moisture, density, etc.)

Weight: 1800kg

The air-flow dryer employs high-speed hot air to suspend wet starch particles within it. This equipment is characterized by its high heat transfer coefficient, extensive heat transfer area, and brief drying time. Air-flow drying, also known as the "air-flow dryer," represents the application of dilute-phase conveying in solid fluidization for drying purposes. This method involves direct contact between the heating medium and the solid particles that need to be dried, with the solid particles suspended in the fluid. Consequently, the contact area between the two phases is large, which enhances the heat and mass transfer processes. It is widely utilized in the drying unit operations of bulk materials.

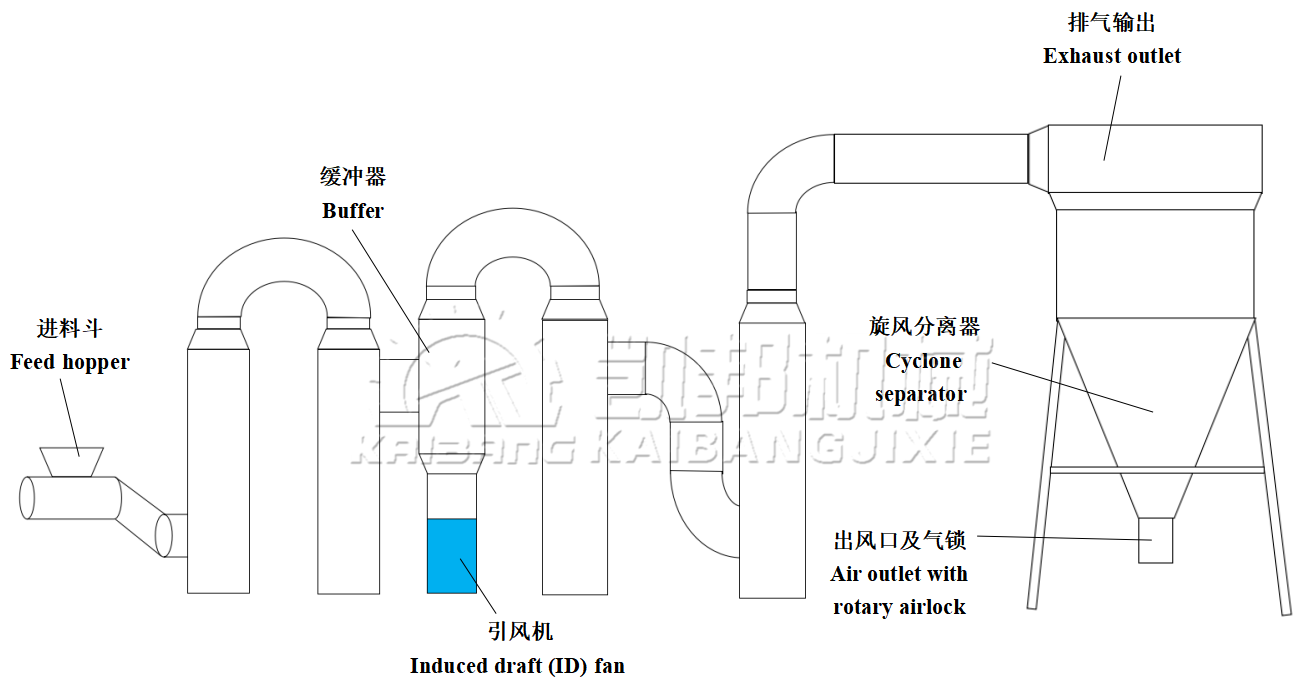

Feeding System:Delivers wet materials into the drying chamber through components such as feed hoppers, screw conveyors, or air conveyors.

Drying Chamber:The cylindrical processing chamber where moisture removal occurs. Its curved pipe design enhances heat distribution.

Heating System:Produces hot air for drying. The heat source is usually located outside the chamber and connected via insulated pipes.

Air Circulation System:Uses fans to distribute heated air evenly throughout the chamber, ensuring uniform drying.

Air Inlet/Outlet:Controlled by fans to regulate airflow. Heated air enters through the inlet and exits through the outlet after absorbing moisture.

Ventilation System:Expels moisture-laden air to prevent condensation and maintain efficient drying conditions.

Discharge System:Removes dried materials from the chamber automatically or manually after completion.

Among the products that have been successfully dried using this series are starch, glucose, fish meal, sugar, cane sugar, distiller's grains, feed, gluten, plastic resins, coal powder, and dyes.

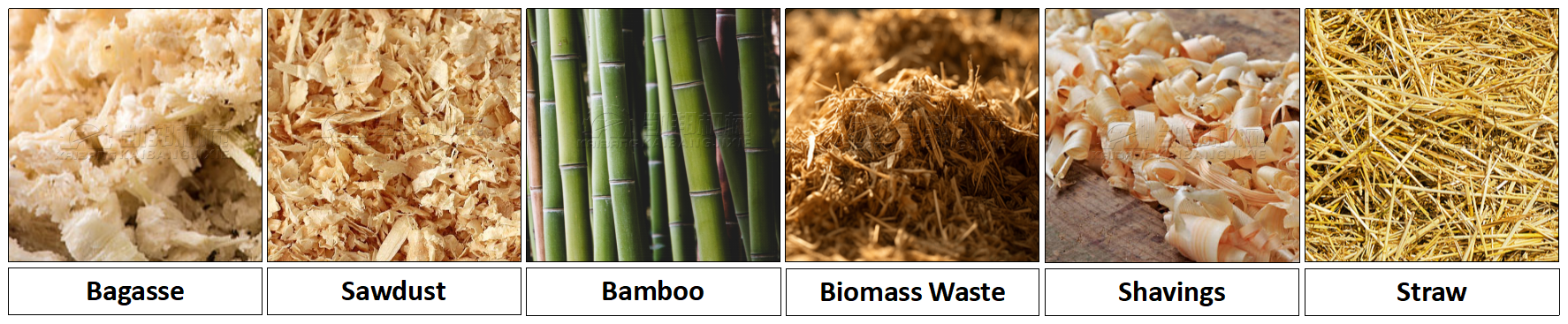

Biomass: Biomass materials such as agricultural residues, straw, like crop stalks, and nut shell.

Wood Chips and Sawdust

Food Products: Such as fruits, grains, vegetables, nuts, and herbs.

Minerals and Ores: Such as gypsum, clay, limestone, and silica sand.

Paper and Pulp

Ceramics and Building Materials: Ceramic materials, clay products, and building materials such as bricks and tiles.

(1)The drying time is short, with a single drying cycle lasting approximately between 2.5 and 5 seconds.

(2)The drying capacity is impressive. Materials in the pneumatic dryer remain suspended, fully exposed to the hot air flow, thus ensuring high drying efficiency.

(3)The pneumatic dryer adopts a serpentine tubular design, making it adaptable to various spaces and occupying minimal floor space.

(4)The pneumatic dryer boasts a long service life and contains no easily damaged parts.

(5)Kaibang Machinery specializes in the manufacture of dryers and charcoal machines. The pneumatic dryers produced by our company are highly automated, capable of adjusting the drying temperature and speed in real time according to product needs, achieving excellent drying results for materials of various humidity levels.

(6)Our pneumatic dryers utilize automatic feeding, which is more convenient than traditional manual feeding and reduces labor costs.

(7)Our pneumatic dryers feature a long drying path and deliver excellent drying results.

(8)Our pneumatic dryers adopt a dust-free design, significantly enhancing the working environment for operators.

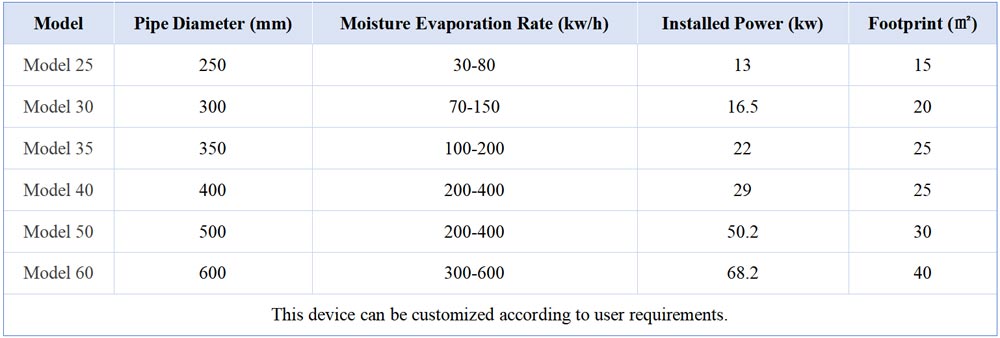

<Note: Henan Kaibang Machinery Manufacturing Co., Ltd. provides customized pneumatic dryer models based on the actual requirements of our customers. The parameters listed above are for reference purposes only.>

Henan Kaibang Machinery Manufacturing Co., Ltd. mainly produces: crushing equipment, drying equipment, forming equipment, pyrolysis reactor equipment, environmental protection equipment, and other complete production line equipment. The company's equipment production, casting and forming, mechanical processing, physical and chemical treatment, to assembly into machines, is fully tracked and inspected by quality testing engineers throughout the process to ensure that users receive high-quality, reliable equipment.

The company has been working hard to build the Kaibang brand for decades, always pursuing excellence, with high-quality staff, strict quality assurance system and perfect after-sales service. We warmly welcome domestic and overseas customers to visit our company for on-site inspection and guidance.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: info@kaibangmachinery.com

Phone: 15638129993

E-mail: +86 15638129993

Whatsapp:86 15638129993

Add: 800 meters east of the intersection of Chuangye Avenue and E23 in Gongyi Industrial Agglomeration Zone, Zhengzhou City, Henan Province, north of the road