Box-type Charcoal Briquettes Drying Machine

Brand: KAIBANG

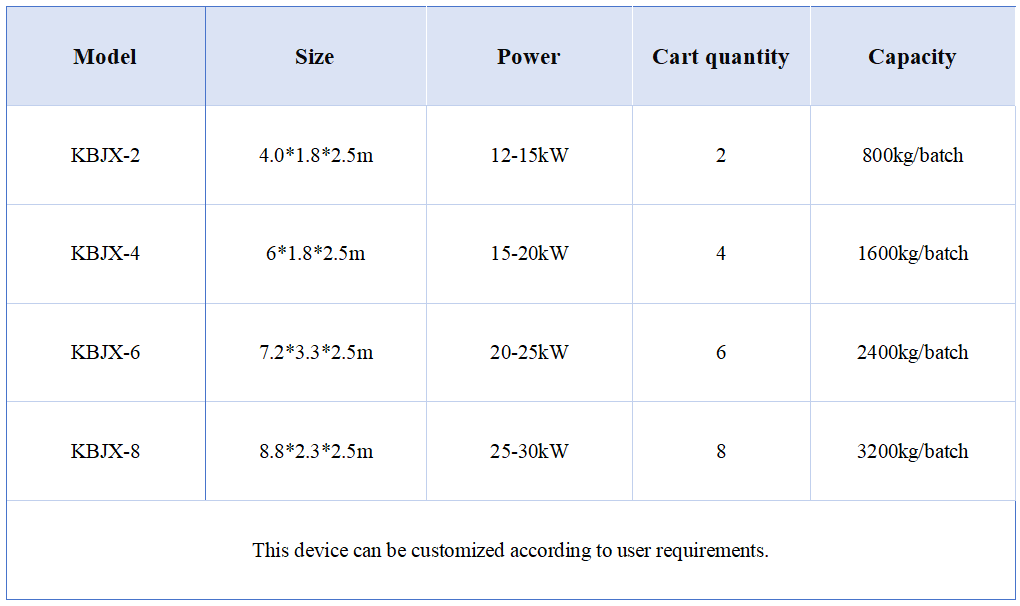

Heating Power: 11.4-14.7kW (Electricity, natural gas, firewood, biomass particles and other heating methods can be used)

Drying Time: 6-24hours/ time (Drying time is affected by factors such as material type, moisture, density, etc.)

The charcoal briquette drying machine, alternately known as a box dryer or drying chamber, is tailored for removing moisture from newly produced charcoal briquettes. This process enhances their quality, making them ideal for storage, transportation, and burning. It plays a vital role in the charcoal production process by guaranteeing the briquettes meet the required moisture level, upgrading product quality, prolonging shelf life, and boosting combustion efficiency. Furthermore, besides drying charcoal, it can also be utilized for drying a wide range of fruits, vegetables, meats, and other items.

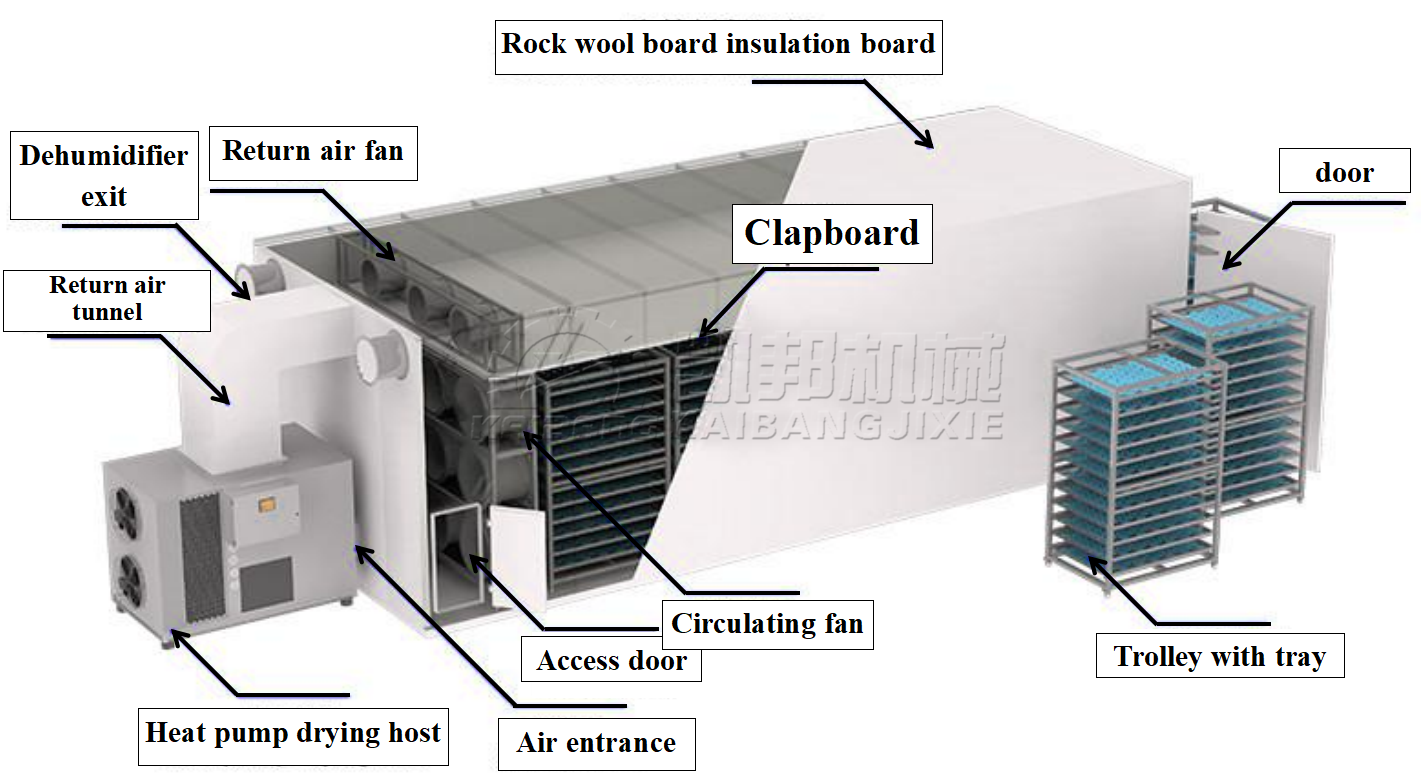

Box-type charcoal dryer is used to reduce moisture content in charcoal. As a batch dryer, it consists of insulation panels, trolleys (optional), trays (optional), fans, electrical control panels and other components. Due to its container-like or chamber-like appearance, it is also referred to as container dryer or drying chamber.

The box-type charcoal drying machine is primarily composed of a thermal insulation chamber, control cabinet, fans, shelves, ventilation ducts, temperature and humidity measurement system, dust removal device, and other components.

Drying Chamber/Box: The main body of the drying machine is a sealed chamber or box where charcoal briquettes or other materials are placed for drying. It is made of galvanized steel plates and insulation boards, providing excellent thermal insulation and heat preservation effects.

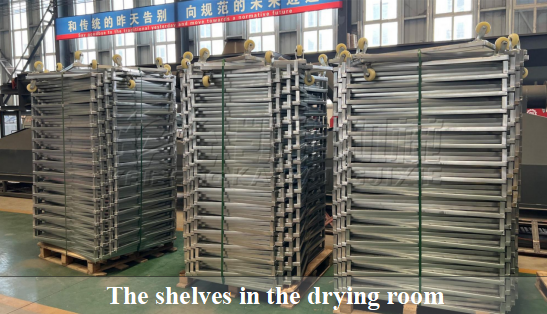

Shelves: Inside the chamber, there are shelves where charcoal briquettes are evenly distributed. These shelves allow for proper airflow around the briquettes, promoting uniform drying. They can be fixed or made into mobile trolleys for convenient and easy loading of materials. The shelves can also be customized according to customer requirements.

Heat Source: The drying machine is equipped with a heat source that can be located inside the chamber (direct heating) or outside (indirect heating). This includes electric heating elements, gas burners, or biomass combustion systems.

Air Circulation System: Fans or blowers are used to evenly circulate heated air throughout the chamber.

Temperature and Humidity Control: This system regulates the drying process and ensures optimal conditions for moisture removal.

Loading: Freshly crafted charcoal briquettes are loaded onto the trays within the drying chamber, ensuring an even distribution for efficient drying.

Heating: The heat source is engaged to generate the thermal energy necessary for the drying process. In a direct heating system, the heat source is situated inside the chamber, directly warming the air surrounding the briquettes. Conversely, in an indirect heating system, the heat is generated externally and transferred into the chamber via convection or conduction.

Air Circulation: Fans or blowers are utilized to circulate the heated air throughout the entire chamber. This air movement guarantees that moisture evaporated from the briquettes is efficiently carried away, maintaining a consistent drying environment.

Dehumidification: As the heated air passes over the charcoal briquettes, it absorbs moisture from their surfaces, progressively decreasing their moisture content. This moisture-laden air is then expelled from the chamber, enabling continuous drying.

Unloading: Upon reaching the desired moisture content, the dried charcoal briquettes are unloaded from the dryer for subsequent processing, packaging, or storage.

The hot air is continually circulated through the ducts surrounding the drying chamber. Inside the drying oven, the material is heated and dried through the circulation of hot air. The drying oven is furnished with a moisture exhaust outlet to effectively eliminate water vapor and ensure optimal drying results.

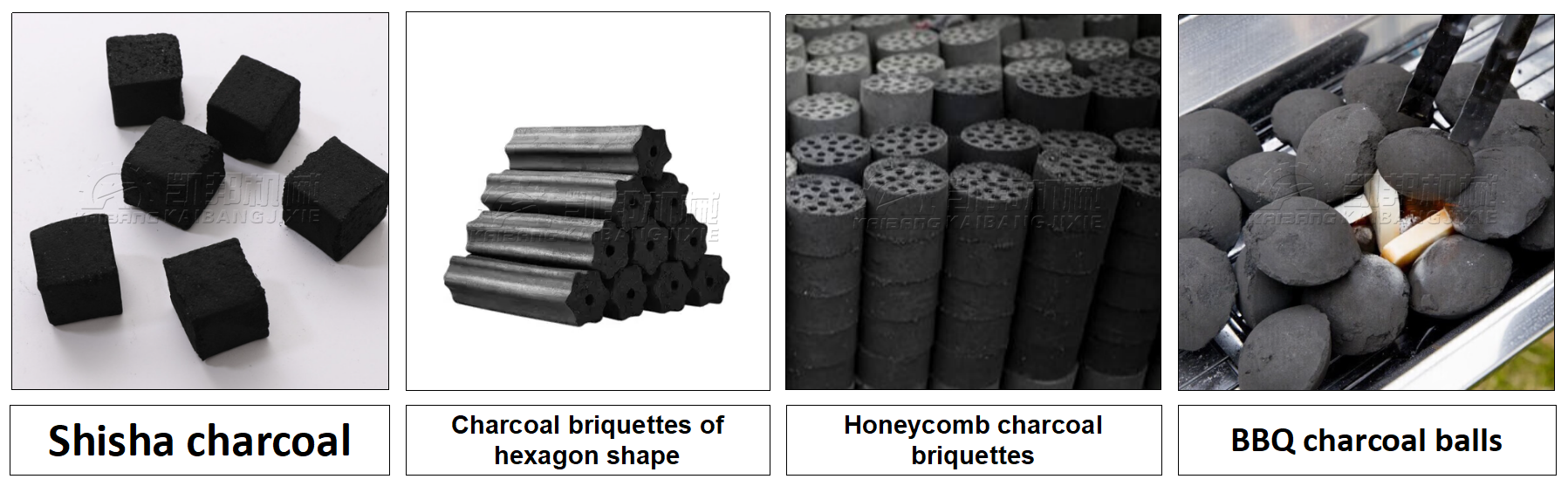

The box-type charcoal drying chamber boasts a versatile application spectrum, spanning charcoal, food, agricultural byproducts, fruits, traditional Chinese medicinal herbs, aquatic products, and numerous other fields. For charcoal processing factories, the raw materials typically encompass shisha charcoal, honeycomb charcoal blocks, and barbecue charcoal balls.

Charcoal Drying: Charcoal briquette dryers play a pivotal role in ensuring freshly produced charcoal briquettes are thoroughly dried before packaging, storage, or further processing.

Barbecue Charcoal Drying: Charcoal briquette dryers are commonly employed in the production of both household and commercial barbecue charcoal. They guarantee easy ignition, prolonged burning durations, and minimal smoke emission during the barbecue process.

Food Industry: Box-type drying chambers are also versatile in drying fruits, vegetables, meats, herbs, spices, grains, and various other food items. These chambers aid in reducing moisture content and preserving quality for subsequent storage or processing.

1.It is an intelligent device that integrates dehumidification, heating, exhaust temperature control, and precise temperature regulation.

2.The unique exhaust heat recovery design minimizes heat loss, enhancing overall energy efficiency.

3.It offers high intelligence by adjusting temperature and humidity according to the specific properties of the materials.

4.The drying process requires no manual supervision. The unit will automatically shut off once the materials are fully dried or reach the desired drying temperature.

5.It is extremely easy to install and dismantle, with a compact footprint suitable for both indoor and outdoor use.

<Note: With continuous technological upgrades, all parameters are provided for reference only. In case of any modifications, please refer to the actual product for accuracy.>

Henan Kaibang Machinery Manufacturing Co., Ltd. mainly produces: crushing equipment, drying equipment, forming equipment, pyrolysis reactor equipment, environmental protection equipment, and other complete production line equipment. The company's equipment production, casting and forming, mechanical processing, physical and chemical treatment, to assembly into machines, is fully tracked and inspected by quality testing engineers throughout the process to ensure that users receive high-quality, reliable equipment.

The company has been working hard to build the Kaibang brand for decades, always pursuing excellence, with high-quality staff, strict quality assurance system and perfect after-sales service. We warmly welcome domestic and overseas customers to visit our company for on-site inspection and guidance.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: info@kaibangmachinery.com

Phone: 15638129993

E-mail: +86 15638129993

Whatsapp:86 15638129993

Add: 800 meters east of the intersection of Chuangye Avenue and E23 in Gongyi Industrial Agglomeration Zone, Zhengzhou City, Henan Province, north of the road