Comprehensive Wood Crusher

Brand: KAIBANG

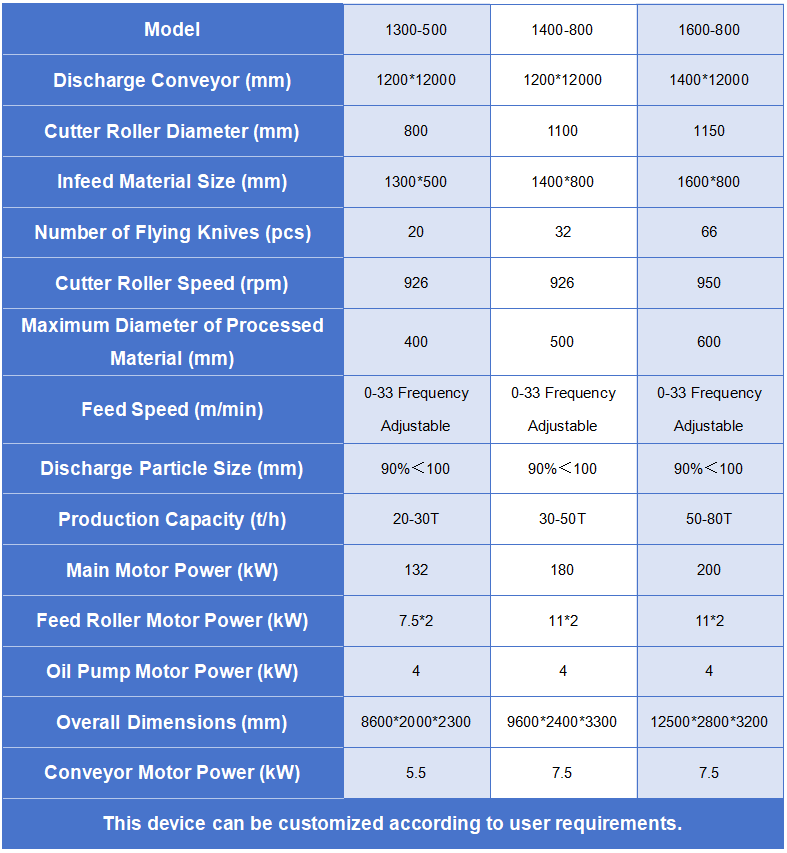

Capacity: 20-120t/h

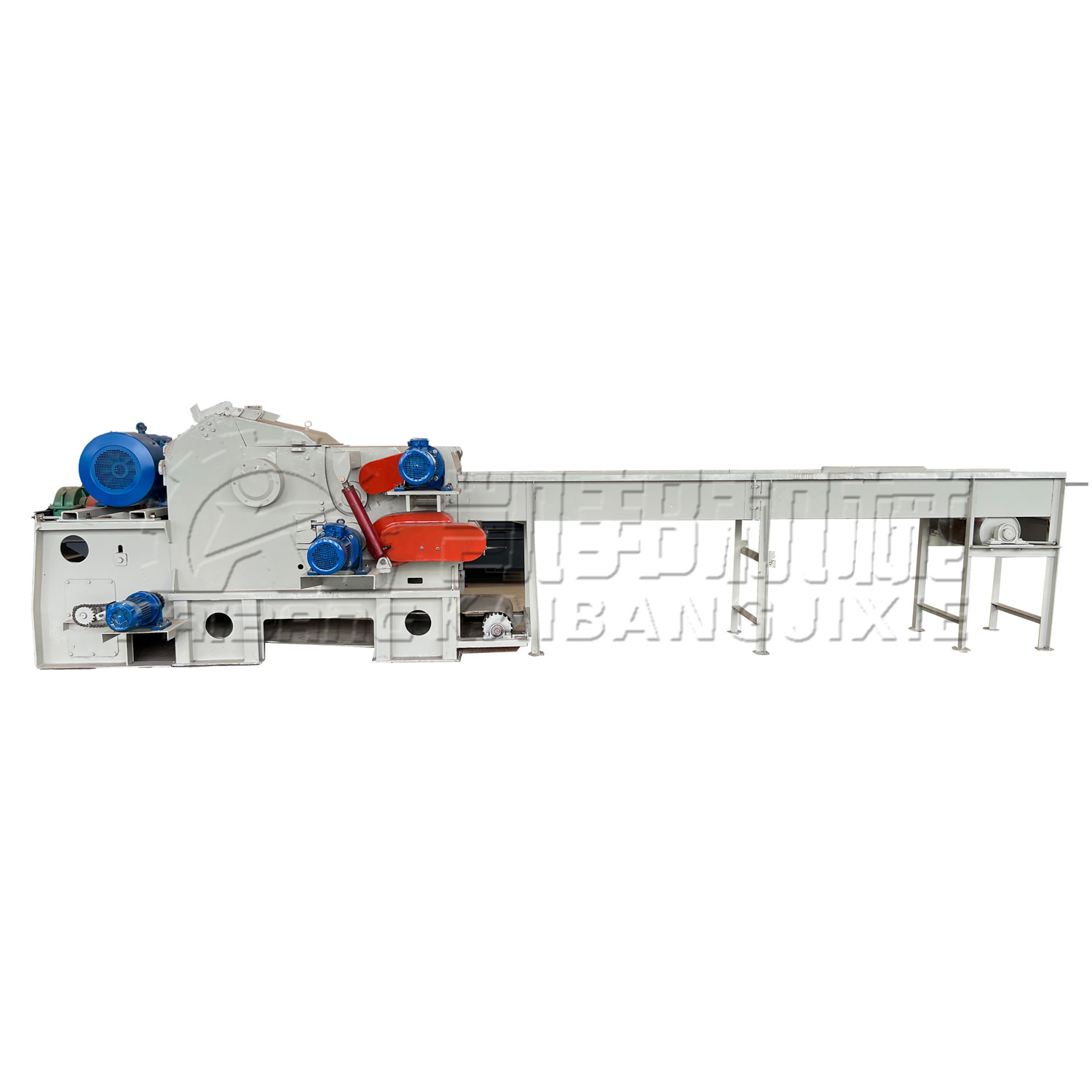

The comprehensive crusher is presently the preferred pre-boiler feedstock crushing equipment for biomass power plants, both domestically and internationally. It features a compact and rational structure, ease of operation, high production capacity, wide material adaptability, high-quality crushing granularity, safety, reliability, and convenient maintenance. It stands as the most advanced and safest type of crusher currently available in China.

The biomass shredder is a versatile crushing device capable of shredding a wide range of large materials, such as large-diameter logs, tree roots, and various weeds. It utilizes a direct drive system with robust motorization, efficiently and safely converting any biomass into chips for use as biomass energy. The biomass comprehensive crusher, which is equipped with a bale breaker, is ideal for processing various round bale crops, including rice straw, corn stalks, and cotton stalks. Featuring a compact and rational structure, ease of operation, high production capacity, high-quality crushing granularity, safety, reliability, and convenient maintenance, it adopts a chain plate for feed conveyance to ensure smoother feeding and significantly boost production capacity. It stands as the preferred equipment choice for biomass power plants.

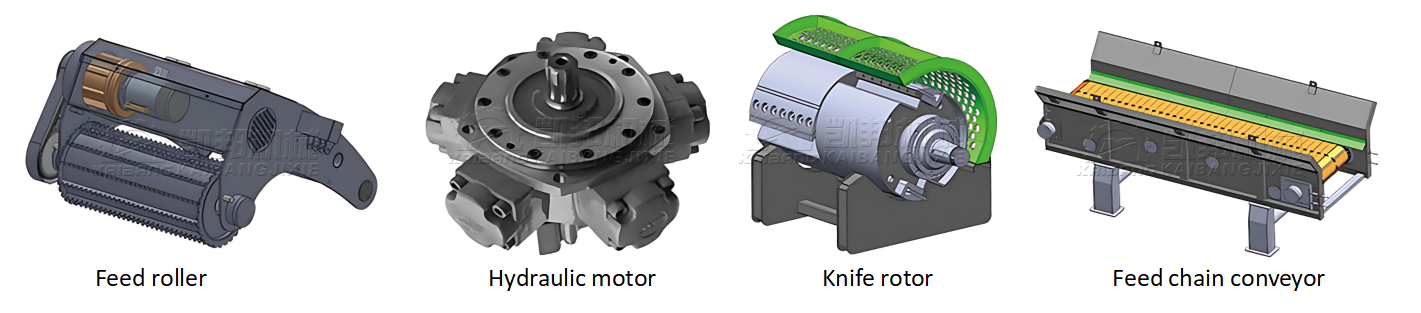

The comprehensive crusher is a mechanical device specifically designed to crush inputted wood and process it into block-shaped products. Its core structure comprises:

A flexible and maneuverable vehicle body equipped with a traveling mechanism, facilitating movement between different work sites.

A high-efficiency rotating crushing device located at one end of the vehicle body, which, through precise mechanical operation, pulverizes and shapes the wood into the desired form.

A vane-type feeding device installed on top of the rotating crushing device, responsible for orderly and continuous introduction of wood into the crushing device to ensure smooth and efficient crushing.

A conveyance device extending from the lower part of the rotating crushing device to the other end of the vehicle body in the direction of travel, specifically used to transport and discharge crushed wood, ensuring continuous operation of the production line and smooth external discharge.

And a drive system cleverly arranged between the rotating crushing device and the conveyance device, which not only powers the traveling mechanism but also serves as the source of power for the rotating crushing device, vane-type feeding device, and conveyance device.

The entire drive system is designed compactly with high energy conversion efficiency, ensuring stable operation and powerful performance of the entire machine. This comprehensive design not only enhances the efficiency and quality of wood crushing but also greatly improves the adaptability and operational convenience of the equipment.

There are many kinds of waste wood, such as leftovers from furniture factories, wooden boards after packaging products, wood waste crafts, some branches in forestry, and some slats used in building materials. Waste wood can be seen everywhere around us. Waste wood can be reused, and the reuse of waste wood after being processed and crushed by a wood shredder can beneficially reduce the waste of wood, and it has a great protective effect on the environment.

1.Some models within this series adopt a foundation-free design, enabling them to be installed and operated under various geographical and topographical conditions. Unaffected by seasonal weather and other external conditions, this design saves installation time and reduces the labor, material, and financial costs that would otherwise be incurred in constructing foundations for users.

2.Certain models in this series feature automated control systems, with automatic feeding and discharging, thereby enhancing production capacity and improving the safety coefficient of machine operation by achieving human-machine separation.

3.Some models in this series employ chain plate conveying for feeding, which, compared to traditional belt feeding, ensures smoother feeding and significantly boosts production capacity.

4.All models in this series utilize specially designed small tools independently developed by our company, featuring long service life, low maintenance costs, and high production efficiency.

5.Each model in this series is equipped with a secondary discharging system, allowing users to change the discharging direction according to their needs and operate flexibly.

The comprehensive crusher primarily relies on impact energy to accomplish the wood crushing task. Specifically, when the hammer-type comprehensive crusher is in operation, its motor drives the rotor to rotate at high speed. Wood is evenly fed into the crushing chamber, where the high-speed rotating hammerheads exert intense impacts, shearing, and tearing actions on the wood to achieve crushing. Meanwhile, with the assistance of the wood's own gravity, it is pushed towards the baffle plate and sieve bars inside the crushing frame. At the lower end of the rotor, a sieve plate device is specially installed: crushed wood pieces with particle sizes smaller than the sieve holes can pass through the sieve plate and be discharged smoothly; while wood pieces with particle sizes larger than the sieve holes will be retained by the sieve plate and continue to receive impacts and grinding treatment from the hammerheads until they reach an appropriate particle size. This process ensures fine crushing and efficient processing of the wood.

<Note: With continuous technological upgrades, all parameters are provided for reference only. In case of any modifications, please refer to the actual product for accuracy.>

Henan Kaibang Machinery Manufacturing Co., Ltd. mainly produces: crushing equipment, drying equipment, forming equipment, pyrolysis reactor equipment, environmental protection equipment, and other complete production line equipment. The company's equipment production, casting and forming, mechanical processing, physical and chemical treatment, to assembly into machines, is fully tracked and inspected by quality testing engineers throughout the process to ensure that users receive high-quality, reliable equipment.

The company has been working hard to build the Kaibang brand for decades, always pursuing excellence, with high-quality staff, strict quality assurance system and perfect after-sales service. We warmly welcome domestic and overseas customers to visit our company for on-site inspection and guidance.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: info@kaibangmachinery.com

Phone: 15638129993

E-mail: +86 15638129993

Whatsapp:86 15638129993

Add: 800 meters east of the intersection of Chuangye Avenue and E23 in Gongyi Industrial Agglomeration Zone, Zhengzhou City, Henan Province, north of the road