Rotary Drum Dryer

Brand: KAIBANG

Feed Size:<10mm

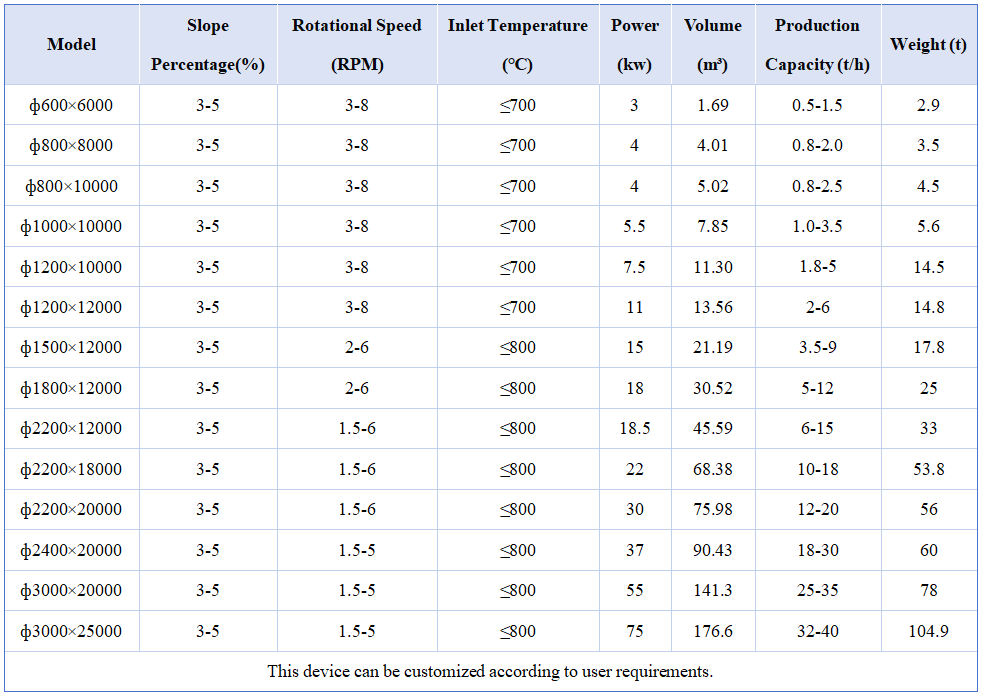

Motor Power:7.5-110KW

Production Capacity:1-7.5 t/h (Production capacity is affected by factors such as material type, moisture, density, etc.)

The rotary drum dryer, also referred to as a drum dryer, is primarily used for drying powdered and granular materials. It is also applicable for processing viscous, pasty, or high-moisture substances. With its advantages of large production capacity, broad applicability, minimal flow resistance, and user-friendly operation, this equipment is widely utilized in industries such as building materials, metallurgy, chemical engineering, and cement production for dehydrating materials like slag, limestone, pulverized coal, and clay.

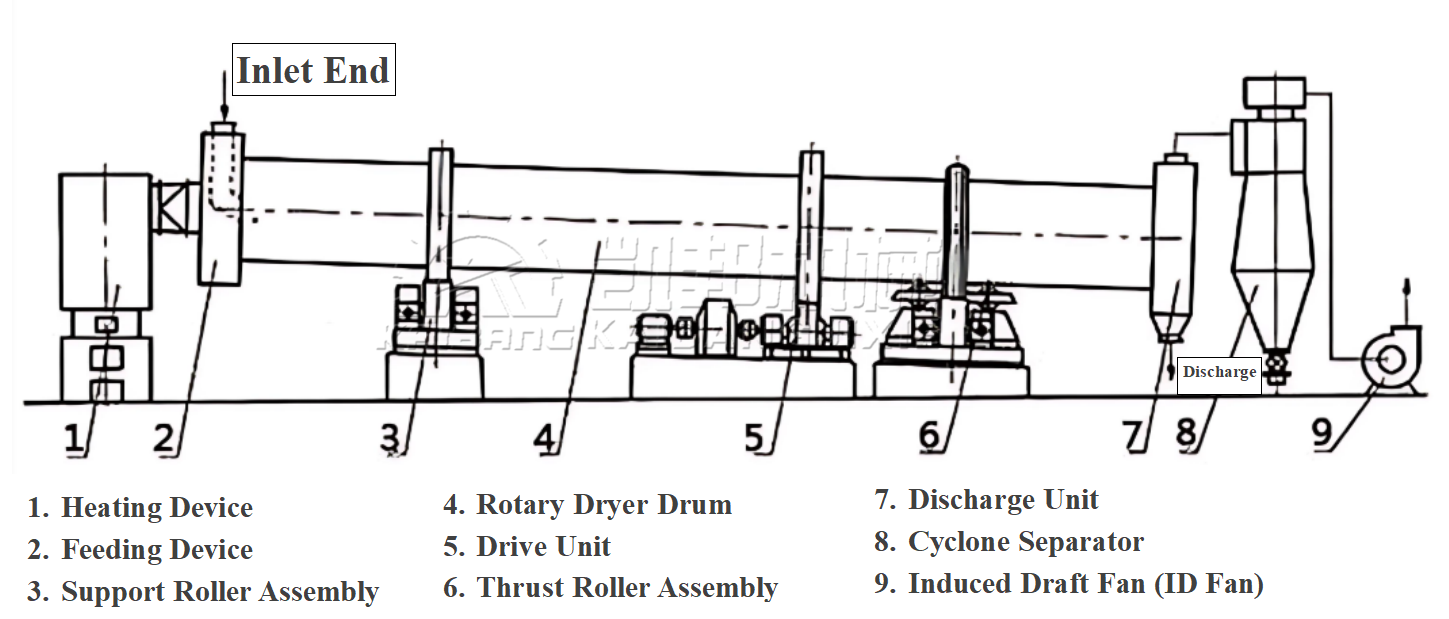

The dryer mainly consists of a rotating cylinder, lifting flights, transmission mechanism, support frame, and sealing components. Its rational structural design and advanced manufacturing technology enable remarkable features such as high efficiency, low energy consumption, stable performance, and ease of operation. These qualities make it well-suited to meet the demands for efficient drying processes across various industrial sectors.

We can design heat source systems tailored to user specifications, including coal gasifiers, biomass burners, combustion units, etc. Auxiliary equipment such as metering feeders, belt conveyors, bucket elevators, cyclone dust collectors, induced draft fans, and other components can also be provided based on specific operational needs.

The material to be dried is transported to the dryer's feed inlet via belt conveyors or bucket elevators, then enters the dryer from the upper end through the feeding chute. The heating medium (typically hot air or flue gas) enters from the lower end, either in countercurrent contact with the material or cocurrently through the cylinder. As the cylinder rotates, the material gradually moves toward the lower end under gravity.Lifting flights installed on the inner wall of the cylinder continuously scoop up and cascade the material, ensuring thorough contact with the hot airflow. This enhances drying efficiency and facilitates material progression. During this process, the material absorbs heat directly or indirectly from the heating medium, evaporating moisture to achieve drying. The dried material is finally discharged at the outlet end through belt conveyors or screw feeders.

The heat carrier typically includes hot air and flue gas. After passing through the dryer, the heat carrier usually needs to go through a cyclone dust collector to capture the material particles carried in the gas. If further reduction of dust content in the exhaust gas is required, it should be treated by a bag filter or wet scrubber before being discharged.

(1)In industries such as chemicals, mining, and metallurgy, materials like ore, slag, coal, metal powder, clay, diatomite, and kaolin are processed.

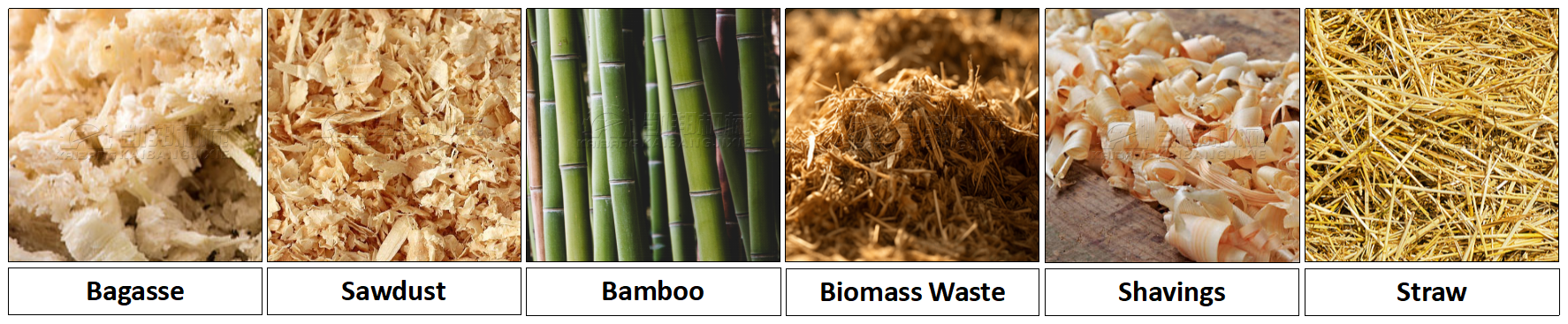

(2)In the agriculture, feed, and fertilizer industries, materials such as straw, forage, leaves, fish meal, corn paste, starch residue, distiller's grains, herbal residues, fruit residues, soy sauce residue, sugarcane residue, peat moss, organic composite fertilizers, sludge, aquatic waste, food factory waste, slaughterhouse waste, as well as organic and inorganic fertilizers and ammonium sulfate phosphate are utilized.

(3)This equipment is also suitable for drying powdered and granular materials with special requirements, encompassing various crystals, light calcium carbonate, activated white clay, magnetic powder, graphite, inorganic mud, pottery clay, lime slurry, ore slurry, phosphorus slag, and red mud from aluminum plants.

(4)It is specifically designed for materials that require low-temperature drying and need to be dried in large quantities continuously.

<Note: Henan Kaibang Machinery Manufacturing Co., Ltd. offers customized roller dryer models tailored to customer needs. The parameters listed above are for reference purposes only.>

Henan Kaibang Machinery Manufacturing Co., Ltd. mainly produces: crushing equipment, drying equipment, forming equipment, pyrolysis reactor equipment, environmental protection equipment, and other complete production line equipment. The company's equipment production, casting and forming, mechanical processing, physical and chemical treatment, to assembly into machines, is fully tracked and inspected by quality testing engineers throughout the process to ensure that users receive high-quality, reliable equipment.

The company has been working hard to build the Kaibang brand for decades, always pursuing excellence, with high-quality staff, strict quality assurance system and perfect after-sales service. We warmly welcome domestic and overseas customers to visit our company for on-site inspection and guidance.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: info@kaibangmachinery.com

Phone: 15638129993

E-mail: +86 15638129993

Whatsapp:86 15638129993

Add: 800 meters east of the intersection of Chuangye Avenue and E23 in Gongyi Industrial Agglomeration Zone, Zhengzhou City, Henan Province, north of the road