Disc type tree root crusher machine

Brand: KAIBANG

Origin:Henan, China

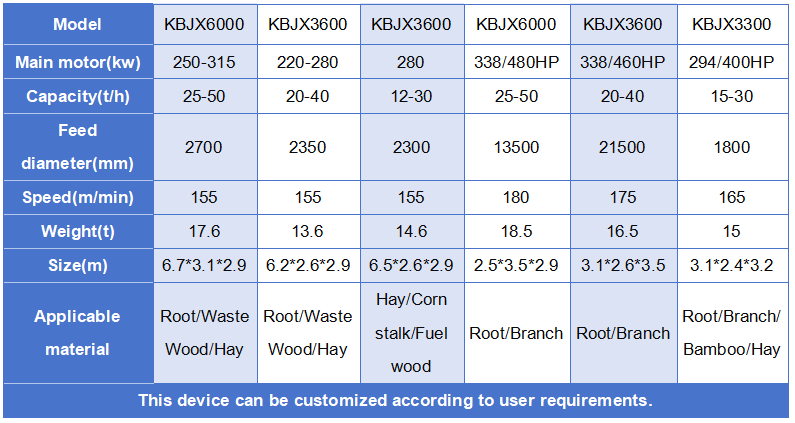

Capacity:Customized

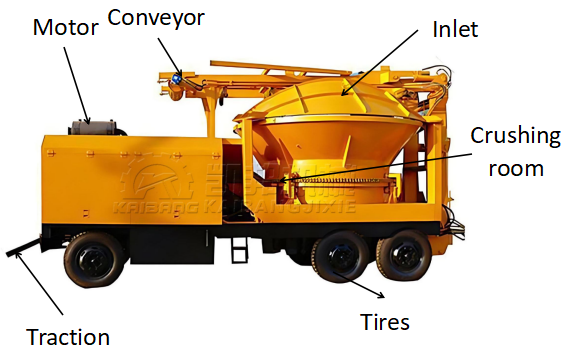

Type:Mobile type

Used for:tree root, other wood.

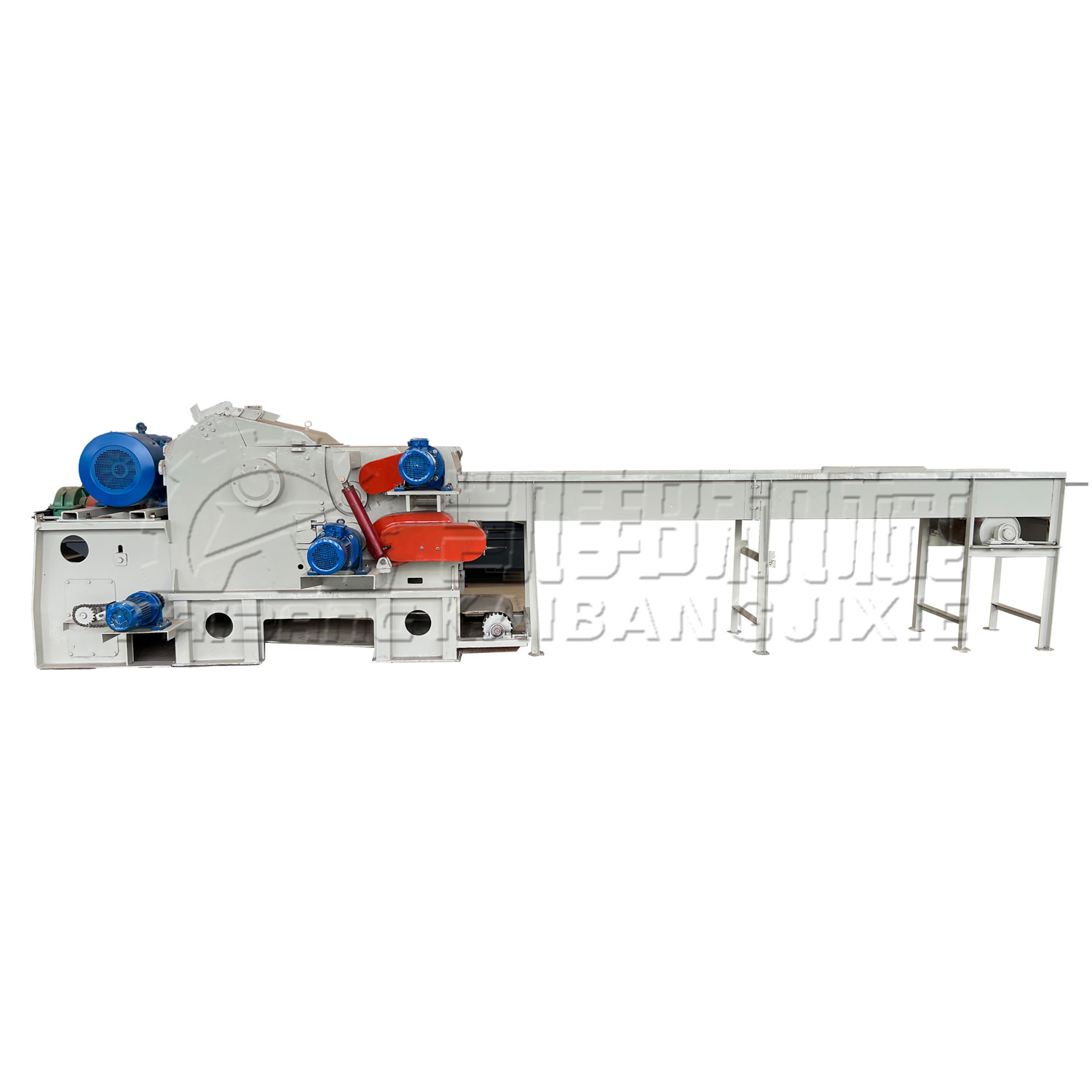

The disc-type root/stump grinder is a large-scale wood processing equipment meticulously developed by our company, integrating advanced technologies from home and abroad. This equipment adopts a modular design and primarily consists of the following core components: frame, housing, high-efficiency power system, hydraulic system, electrical system, and an innovative rotating hopper mechanism. The rotating hopper is controlled by a dedicated drive mechanism, with a crushing rotor driven by an independent drive unit positioned beneath it. The equipment innovatively adopts an offset design between the feed inlet and the center of the hopper, ensuring more uniform and efficient material crushing.

After being precisely loaded into the hopper by the grab crane, the material is uniformly conveyed to the crushing area through the rotation of the hopper equipped with built-in material guiding plates. The high-speed rotating rotor, equipped with specially designed wear-resistant blades, achieves primary crushing through multiple forces including shearing, impacting, and tearing. The initially crushed material does not drop under gravity and continuous rotor impact. The equipment is equipped with a graded screen system, through which qualified materials are discharged, while unqualified materials undergo secondary or multiple crushing in the crushing chamber until meeting the predetermined particle size standards. This design realizes a continuous and automated crushing process, ensuring stable crushing efficiency and finished product quality.

1.Advanced Technology Integration: The equipment adopts an innovative offset feed inlet design combined with auxiliary feeding teeth on the inner wall of the hopper, significantly enhancing feeding efficiency. Additionally, the equipment employs frequency conversion technology. When the rotor load becomes excessive, the system automatically activates the hopper's reverse rotation function, effectively preventing material jams and ensuring continuous and stable operation.

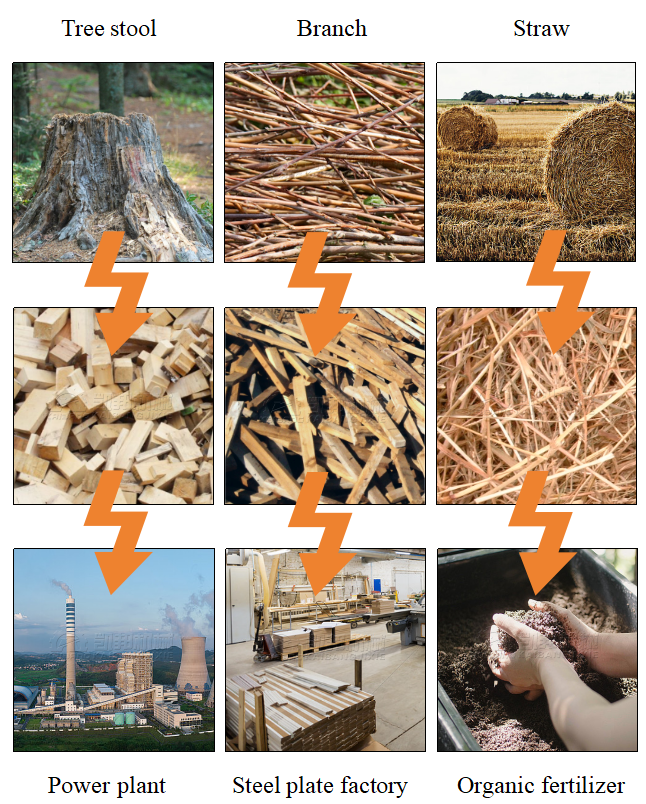

2.Wide Application Range: With powerful crushing capabilities, this equipment is suitable for processing large-diameter materials such as tree roots and scrap furniture, while also efficiently shredding baled straw. Furthermore, it excels in pulverizing small-diameter wood and slab waste, featuring rapid feeding and efficient processing to meet diverse production needs.

3.Convenient Maintenance: Equipped with a hydraulic hopper rotating device, the equipment allows for large-angle rotation during maintenance, fully exposing the rotor section for easy inspection and repair. This design significantly reduces manual operations, improves maintenance efficiency, and shortens downtime.

4.Cost-Effective Production: The multi-blade rotor cutter design ensures thorough and efficient material grinding. Through rational structural layout and advanced material application, the blade lifespan is greatly extended, reducing maintenance and replacement costs and effectively controlling overall production expenses.

5.High Automation: The equipment realizes automatic control of all electrical components, supporting remote wireless operation. This reduces manual intervention, not only enhancing production efficiency but also further ensuring production safety. The elevated automation level simplifies equipment operation and adapts to the intelligent demands of modern production.

<Note: With continuous technological upgrades, all parameters are provided for reference only. In case of any modifications, please refer to the actual product for accuracy.>

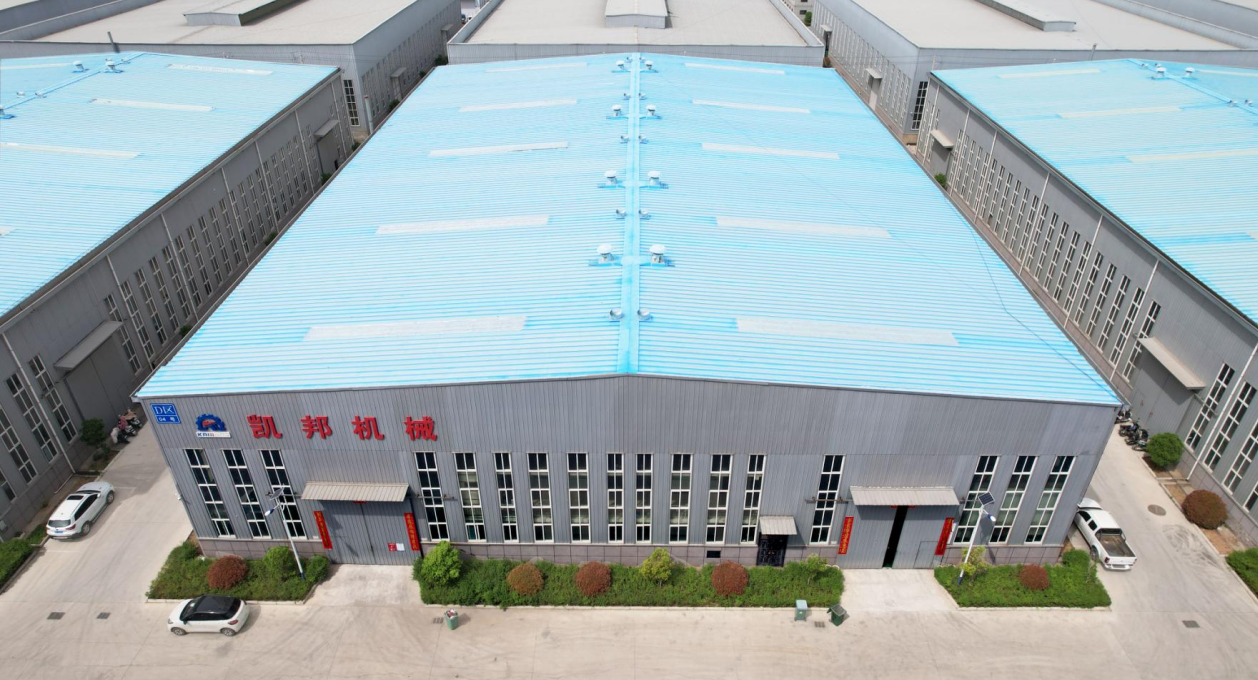

Henan Kaibang Machinery Manufacturing Co., Ltd. mainly produces: crushing equipment, drying equipment, forming equipment, pyrolysis reactor equipment, environmental protection equipment, and other complete production line equipment. The company's equipment production, casting and forming, mechanical processing, physical and chemical treatment, to assembly into machines, is fully tracked and inspected by quality testing engineers throughout the process to ensure that users receive high-quality, reliable equipment.

The company has been working hard to build the Kaibang brand for decades, always pursuing excellence, with high-quality staff, strict quality assurance system and perfect after-sales service. We warmly welcome domestic and overseas customers to visit our company for on-site inspection and guidance.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: info@kaibangmachinery.com

Phone: 15638129993

E-mail: +86 15638129993

Whatsapp:86 15638129993

Add: 800 meters east of the intersection of Chuangye Avenue and E23 in Gongyi Industrial Agglomeration Zone, Zhengzhou City, Henan Province, north of the road