Sawdust Wood Crusher Machine

Wood Crusher for Making Sawdust from All Wood Wastes

Wood crusher to turn wood chips to sawdustt

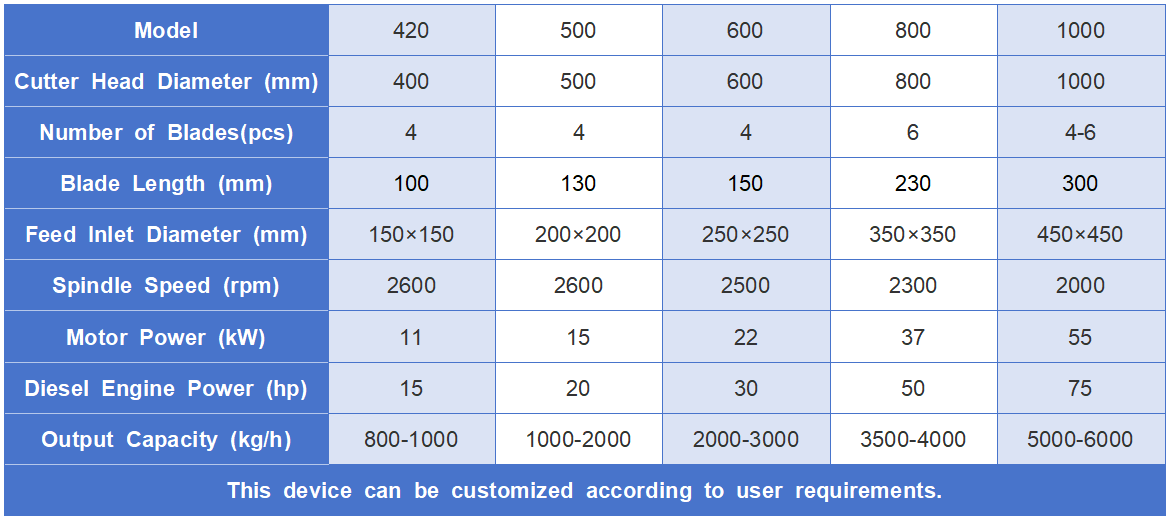

Model:500

Power: 15kW

Processing Capacity: 1000-2000kg/h

We have rich production experience, independent technical R & D team, and excellent quality of all products. In addition, we can provide customized production, overseas installation training and other services to our customers.

We're here to help: Easy ways to get the answers you need.

The wood chipping machine, also known as a sawdust crusher or sawdust machine, is a specialized wood crushing equipment series developed through years of research and design, tailored to meet the needs of China's industrial production. Thanks to its rational design, compact structure, safety features, durability, and high production efficiency, it has achieved excellent results after being promoted and put into use. The entire equipment set is powered by only one electric motor, boasting low noise levels, a simple structure, a compact layout, an affordable price, stable operation, low energy consumption, high output, good quality sawdust products, and low processing costs.

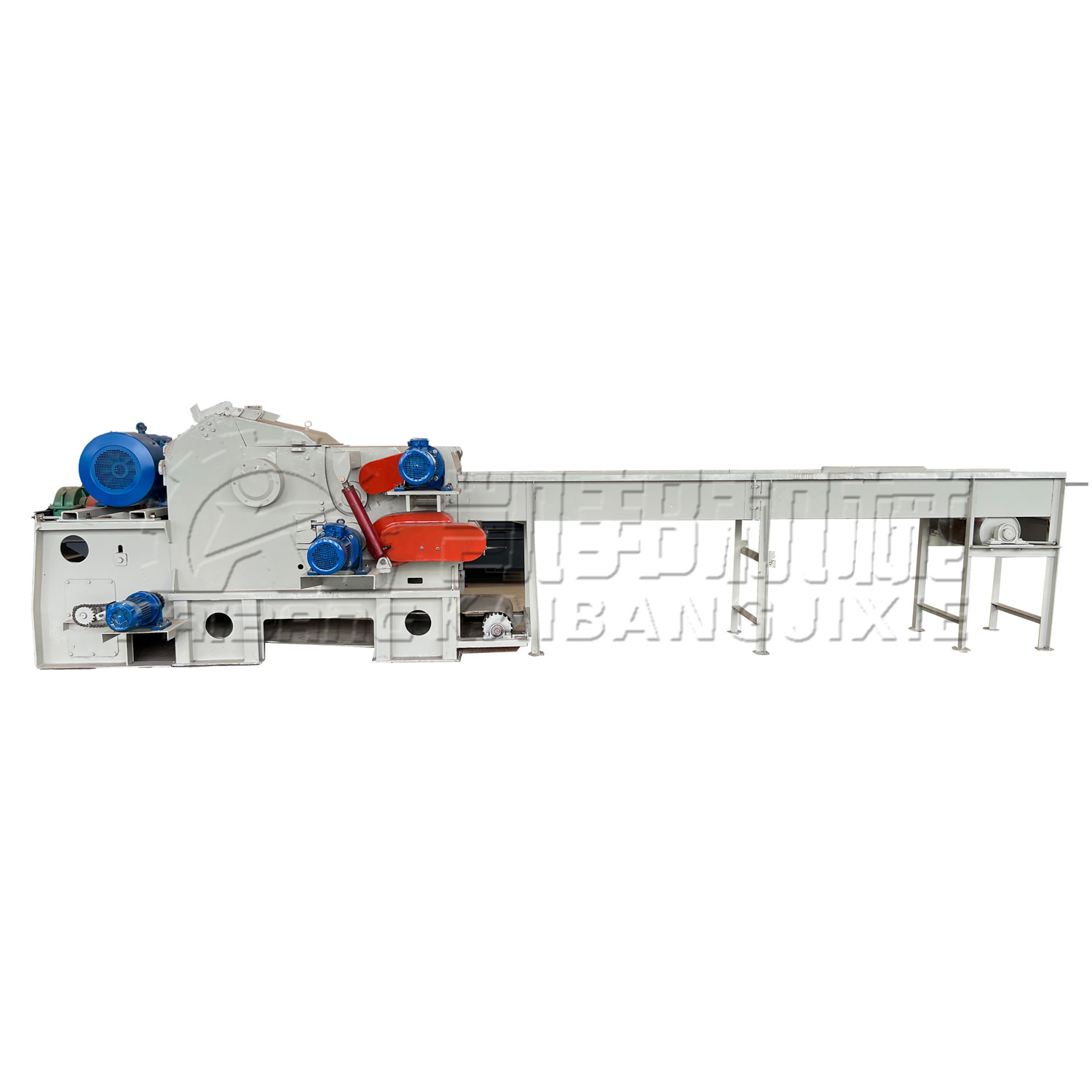

The wood chipping machine is a multifunctional device that integrates chipping, crushing, and pneumatic conveying. It mainly comprises an efficient chipping unit, a precise crushing unit, and a strong fan system. Specifically designed for processing rod-shaped materials with diameters between 5 and 20 centimeters, as well as boards up to 20 centimeters wide, this machine efficiently converts them into sawdust fragments. Besides its compact structure and small occupied area, it also excels in production capacity and boasts great mobility, enabling it to adapt to diverse working conditions.

Widely applied in small charcoal manufacturing factories and feed processing industries, this machine offers users a convenient and highly efficient sawdust processing solution, thanks to its small size and substantial output.

The wood chipping machine combines blade cutting with high-speed airflow impact, offering dual crushing functions and simultaneously completing the micro-material sorting and processing steps. During the blade cutting and crushing process, the rotor generates a high-speed airflow that rotates in tandem with the blade’s cutting direction. The material accelerates within this airflow and undergoes repeated impacts, undergoing dual crushing and thus enhancing the crushing efficiency.

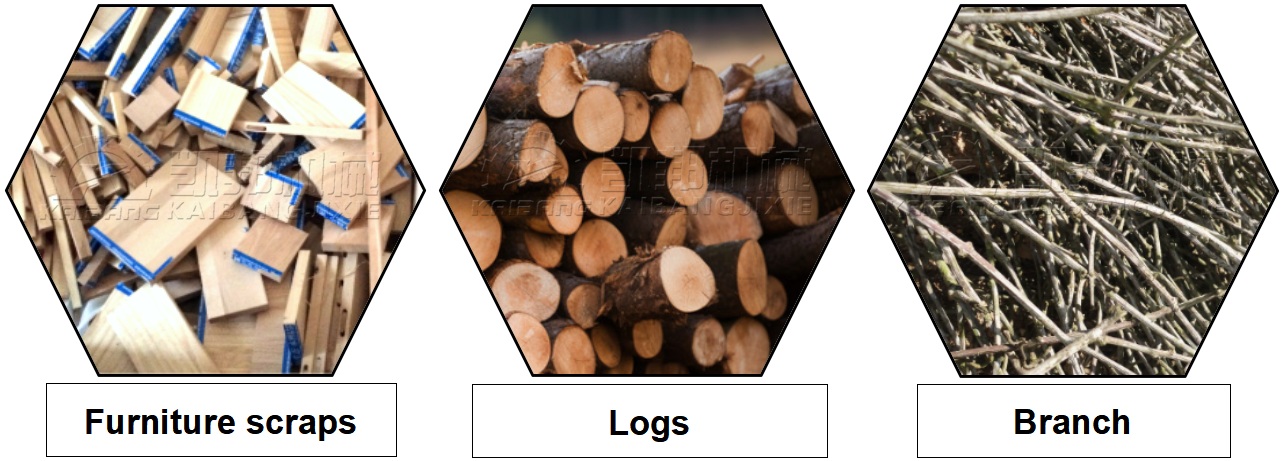

The wood chipping machine is particularly suited for processing sawdust used in edible mushroom culture media. It primarily consists of a chipping device, a crushing device, and a fan. After being chipped by the chipping device, the wood particles are of small granularity and can be directly fed into the crushing device for further processing without the need for drying. The finished sawdust is then conveyed to the collection site by the fan.

This machine integrates slicing and crushing functions into one unit, capable of chipping branches and stems with diameters ranging from 1 to 20 centimeters. Furthermore, it can also be utilized for chipping fibrous stalk materials, including bamboo, thatch, corn stalks, and sorghum stalks. Known alternatively as a wood shaving machine or wood debris crusher, this wood chipping machine is capable of processing various types of wood, such as pine, miscellaneous woods, poplar, fir, and raw bamboo. Thanks to its compact structure, small footprint, high-quality chipping output, low power consumption, and adaptability for mobile operations, it is widely applied in the material preparation sections of small and medium-sized particleboard and fiberboard production enterprises. Additionally, it can be used by individual entrepreneurs for the production of commercial wood chips.

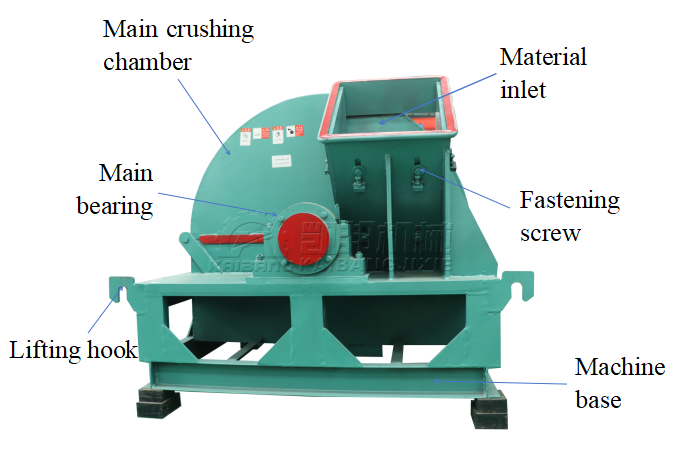

1.The main unit of the wood chipping machine comprises three parts: the rotor, the upper housing, and the lower housing. The crushing chamber incorporates a multi-stage crushing process and fine crushing principle, characterized by high impact force, efficient production, and strong fine crushing capabilities.

2.The entire wood chipping machine is made up of the main unit, fan, analyzer, dust collector, and dust extractor. The components are compactly structured and logically laid out, featuring easy operation, safe usage, excellent sealing performance, and reduced noise levels.

3.The wood chipping machine stands as an ideal front-end device in modern wood powder production processes, integrating wood crushing, wood chip manufacturing, and wood chip pellet preparation functionalities. It encompasses various forms such as wood chippers, wood crushing machines, and wood pelletizers. It can directly convert raw materials like wood and branches into fine wood chips in a single pass, demonstrating multiple advantages including low investment costs, low energy consumption, high production efficiency, and significant economic benefits. Furthermore, the equipment offers great convenience in terms of operation and maintenance.

All fans undergo dynamic balance testing due to their high rotational speeds, which necessitate strict balance requirements, especially for fan impellers that are highly sensitive to peripheral imbalance but less so to minute imbalances in their cores. Based on these characteristics, the following methods can be employed to repair common impeller faults:

Repairing Worn Rivet Heads:If the rivet heads of the impeller are worn, the impeller body and hub can be compressed, and electric welding can be used to build up the worn rivet heads to their original state.

Welding Fatigue Cracks: For fatigue cracks prone to forming at rivet holes, unused new welding rods should be used for welding repairs. This should be done symmetrically around the impeller's axial centerline. After welding the crack, the remaining welding rod should be left in place. A new welding rod should then be used to repair the symmetrical rivet hole crack, ensuring that the remaining welding rod length is the same as that left from the first repair to maintain equal weight addition. If there are no cracks in the symmetrical rivet holes, welding should still be performed there to counteract the added weight from the crack repairs. This symmetric weight addition method can effectively repair cracks.

Performing Simple Dynamic Balance Testing on the Impeller: After supporting the impeller, gently rotate it by hand. The unbalanced area will stop at the lowest point and swing side to side. If there is an imbalance, spot welding can be done on the opposite side of the impeller to add weight for balance, or an angle grinder can be used to remove weld marks from the heavier side to achieve balance. This will restore the fan to normal operation. Note that during fan repair, spot welding should not be done haphazardly with an electric welder, as it may affect the impeller's balance, defeating the purpose of repair and potentially causing greater damage.

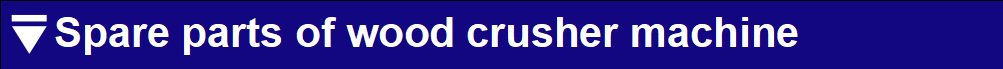

<Note: Because of the variety of materials, the yield and fineness should be determined according to the weight of the material.With continuous technological upgrades, all parameters are provided for reference only. In case of any modifications, please refer to the actual product for accuracy.>

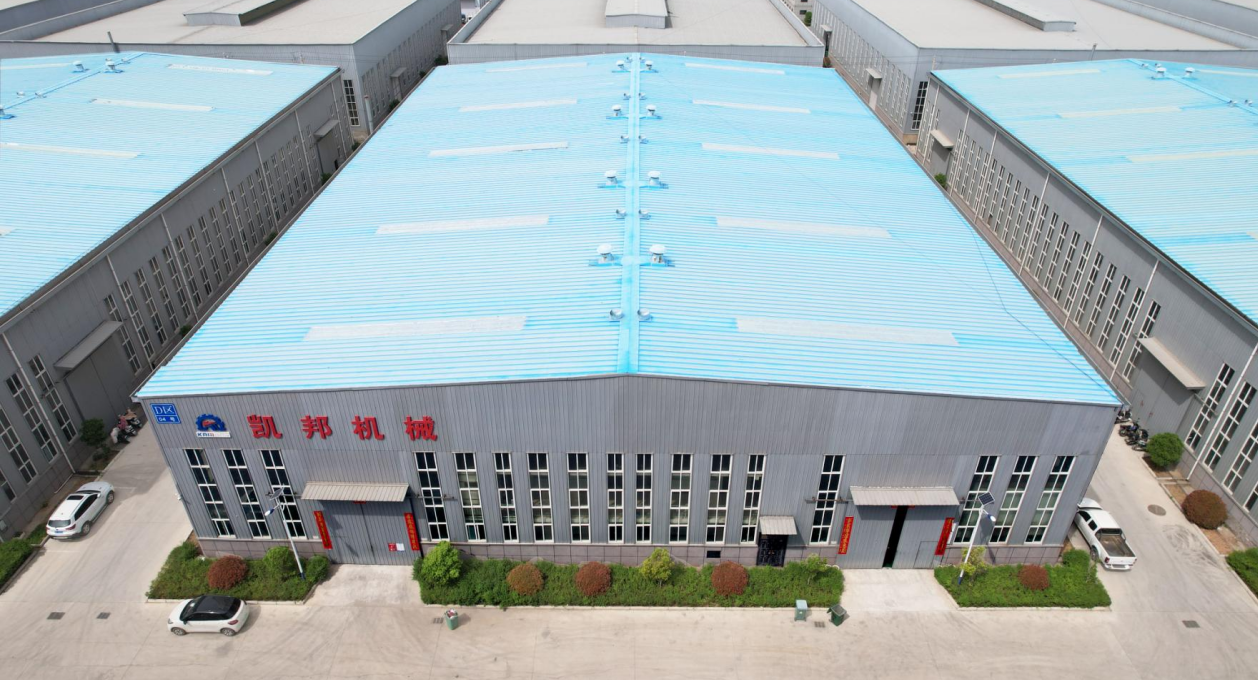

Henan Kaibang Machinery Manufacturing Co., Ltd. mainly produces: crushing equipment, drying equipment, forming equipment, pyrolysis reactor equipment, environmental protection equipment, and other complete production line equipment. The company's equipment production, casting and forming, mechanical processing, physical and chemical treatment, to assembly into machines, is fully tracked and inspected by quality testing engineers throughout the process to ensure that users receive high-quality, reliable equipment.

The company has been working hard to build the Kaibang brand for decades, always pursuing excellence, with high-quality staff, strict quality assurance system and perfect after-sales service. We warmly welcome domestic and overseas customers to visit our company for on-site inspection and guidance.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: info@kaibangmachinery.com

Phone: 15638129993

E-mail: +86 15638129993

Whatsapp:86 15638129993

Add: 800 meters east of the intersection of Chuangye Avenue and E23 in Gongyi Industrial Agglomeration Zone, Zhengzhou City, Henan Province, north of the road