Wood Drum Chipper

Brand: KAIBANG

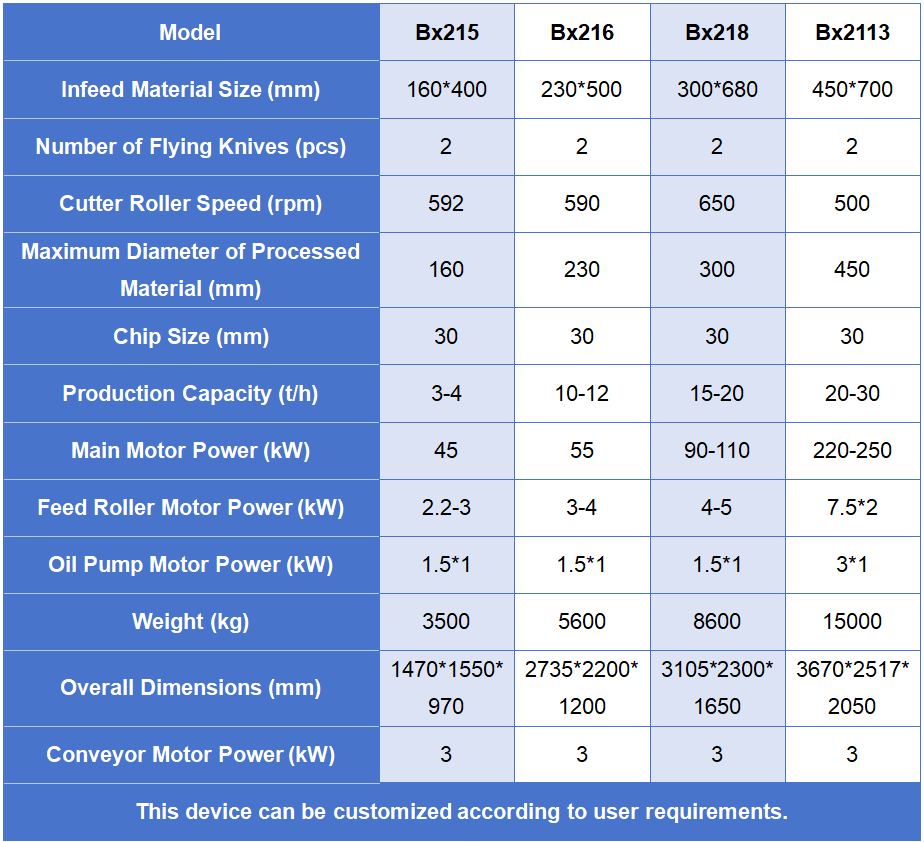

Motor Power: 45-250kw

Capacity: 3-30t/h

Feed Size: 550 * 230mm

Warranty: 1 Year

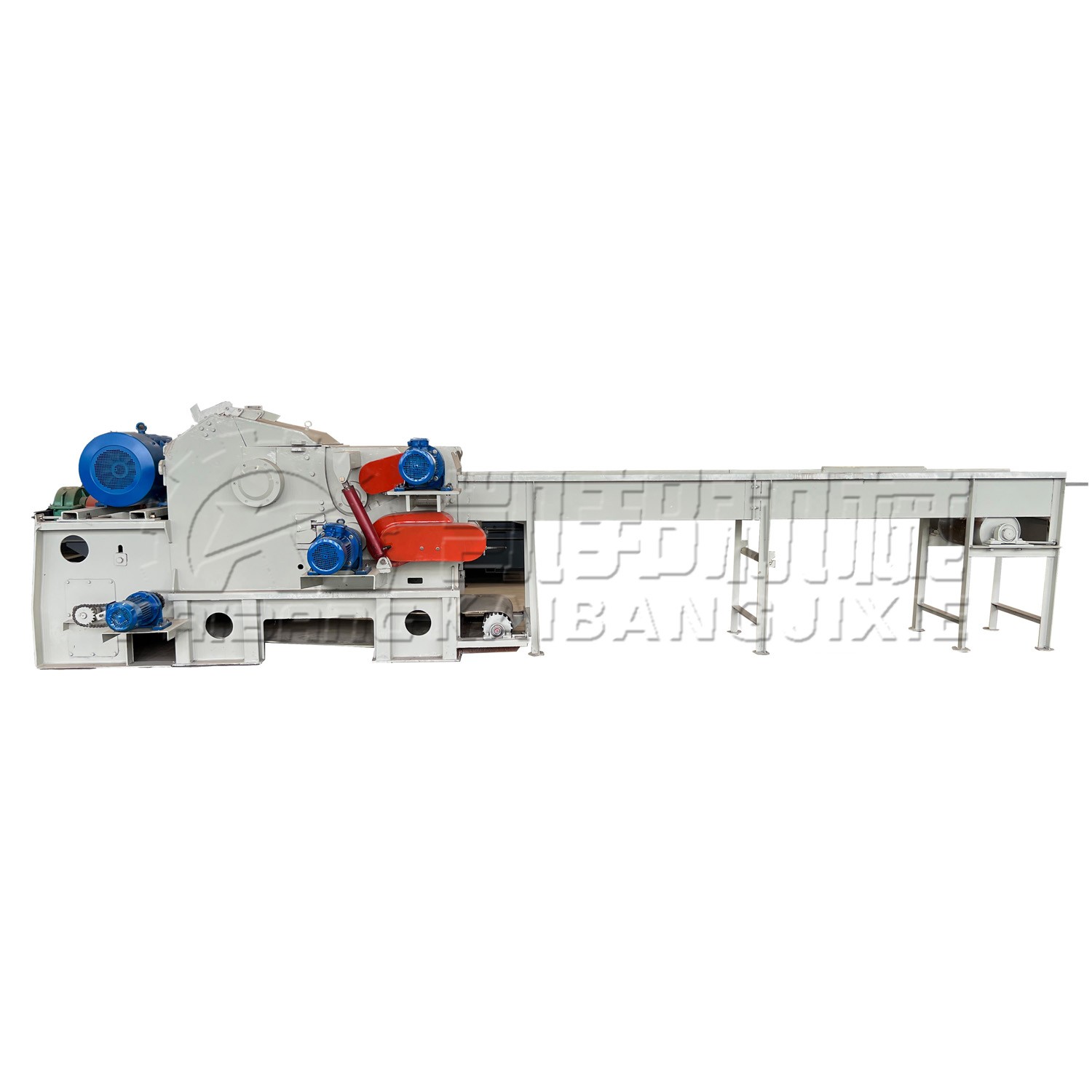

The wood drum chipper is a sophisticated piece of equipment specifically designed for producing high-quality wood chips. It is widely used in paper mills, particleboard factories, fiberboard factories, and wood chip export bases. This machine efficiently converts logs, small-diameter timbers, and other materials into uniformly sized, smoothly cut, and evenly thickened industrial-grade wood chips. Furthermore, it is also capable of accurately cutting branch wood, boards, and other similar materials.

The wood drum chipper boasts powerful and versatile functionality, capable of not only slicing raw materials such as logs, branch wood, veneer scraps, waste plywood, bamboo, cotton stalks, and other non-wooden fibrous stems into chips of specified sizes, but also producing chips that serve as indispensable basic raw materials for manufacturing particleboard, fiberboard, non-wooden artificial boards, as well as for the pulp and paper industry. The chips it produces are of exceptional quality, derived from a wide range of applicable raw materials. Furthermore, the equipment is exceptionally convenient to operate and maintain.

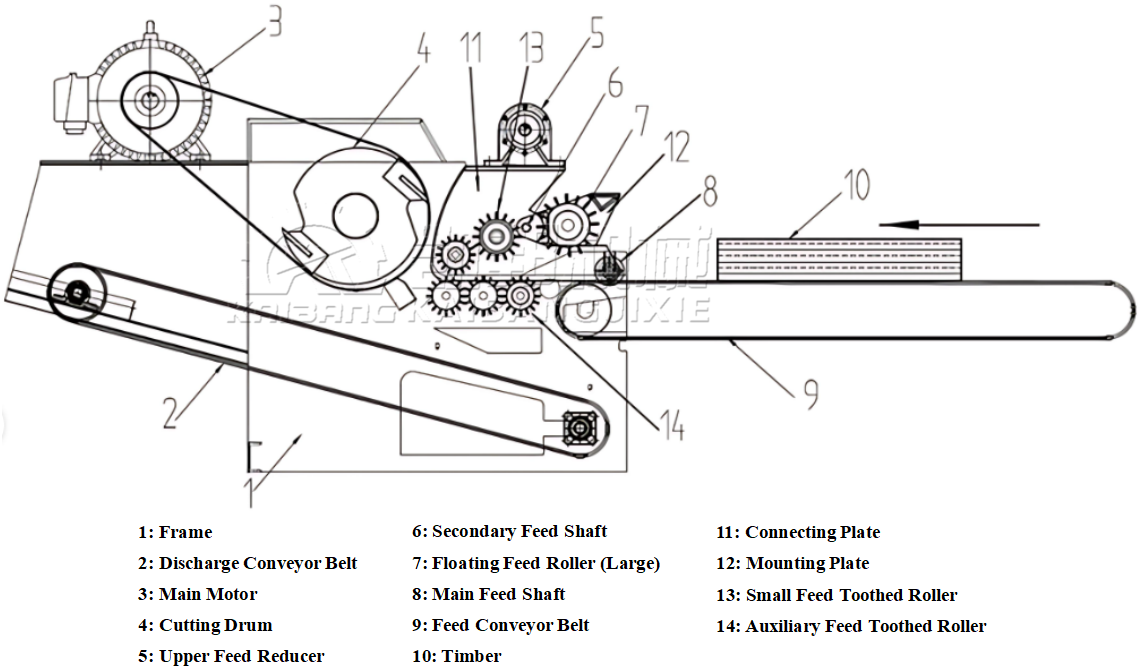

The wood drum chipper is primarily composed of key components such as the machine base, knife roller, upper and lower feed rollers, conveyor belt, and hydraulic system. The machine base, which is welded from high-strength steel plates, provides a solid and stable support foundation for the entire machine. Two fly knives are meticulously installed on the knife roller and securely fastened to it using specially designed fly knife bolts and pressure blocks. Depending on the varying thicknesses of the materials being cut, the upper feed roller assembly can flexibly move up and down within a certain range, thanks to the hydraulic system. During the cutting process, qualified wood chips smoothly pass through the mesh holes and are discharged from the bottom, while larger chips are further cut within the machine to ensure that all the produced wood chips meet the specified requirements.

Furthermore, the hydraulic system of the drum chipper supplies oil to the cylinder via a manual oil pump, facilitating the opening of the protective casing and thereby simplifying the process of blade replacement. During equipment maintenance, the hydraulic system also facilitates the lifting of the upper feed roller assembly, greatly aiding in the adjustment of the gap between the fly knives and the bottom knives, as well as the installation and removal of the comb plate.

· Working principle: the wood is fed by the feed inlet. When the wood touches the cutting blade, it will be cut by the high-speed rotation of the cutting disc. The wood is sent out by the high-speed steam flow generated by the blades of the cutting disc in the cutting room.

· Structure composition: drum chipper consists of body, cutter roller, upper and lower feeding mechanism, feeding device, hydraulic system and other parts.

· Its frame is welded with high strength steel plate, which is the supporting foundation of the whole drum chipper.

· Two sets of flying knives are installed on the cutter roll, and they are fixed on the cutter roll through the pressure block with specially manufactured bolt.

· According to the different thickness of the cutting material, the upper feeding roller assembly can float up and down within a certain range by means of hydraulic system.

· Cut down the qualified sheet through the screen hole through the bottom discharge, large sheet will be cut in the machine.

· Drum chipper hydraulic system: from hand oil pump to oil cylinder, can start the housing, easy to change the blade, when maintenance can lift up feed roller assembly, easy to adjust the fly blade, the clearance of the bottom knife and the disassembly of the comb plate.

This wood drum chipper can process all kinds of wood and biomass materials such as tree logs, branches, bamboo, pallet, sugercane, slats, twigs, planks, reed stalks, waste wood, etc.

1. Compact structure, simple operation, wide application for wood materials chipping and biomass materials processing.

2. Adopting the double roller feeding system, has a higher efficiency than the common one.

3. The chipper body is made of high strength steel, firm, shock-resistant, with less noise.

4. A series of screen for choice, can process wood chips with a variety of size and thickness for different requirements.

5. Special design and reliable blades layout, works more efficiently. The wood chips is of even length and uniform thickness.

6. With the hydraulic buffer system, the maintenance of the chipping machine is simple.

<Note: With continuous technological upgrades, all parameters are provided for reference only. In case of any modifications, please refer to the actual product for accuracy.>

Henan Kaibang Machinery Manufacturing Co., Ltd. mainly produces: crushing equipment, drying equipment, forming equipment, pyrolysis reactor equipment, environmental protection equipment, and other complete production line equipment. The company's equipment production, casting and forming, mechanical processing, physical and chemical treatment, to assembly into machines, is fully tracked and inspected by quality testing engineers throughout the process to ensure that users receive high-quality, reliable equipment.

The company has been working hard to build the Kaibang brand for decades, always pursuing excellence, with high-quality staff, strict quality assurance system and perfect after-sales service. We warmly welcome domestic and overseas customers to visit our company for on-site inspection and guidance.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: info@kaibangmachinery.com

Phone: 15638129993

E-mail: +86 15638129993

Whatsapp:86 15638129993

Add: 800 meters east of the intersection of Chuangye Avenue and E23 in Gongyi Industrial Agglomeration Zone, Zhengzhou City, Henan Province, north of the road