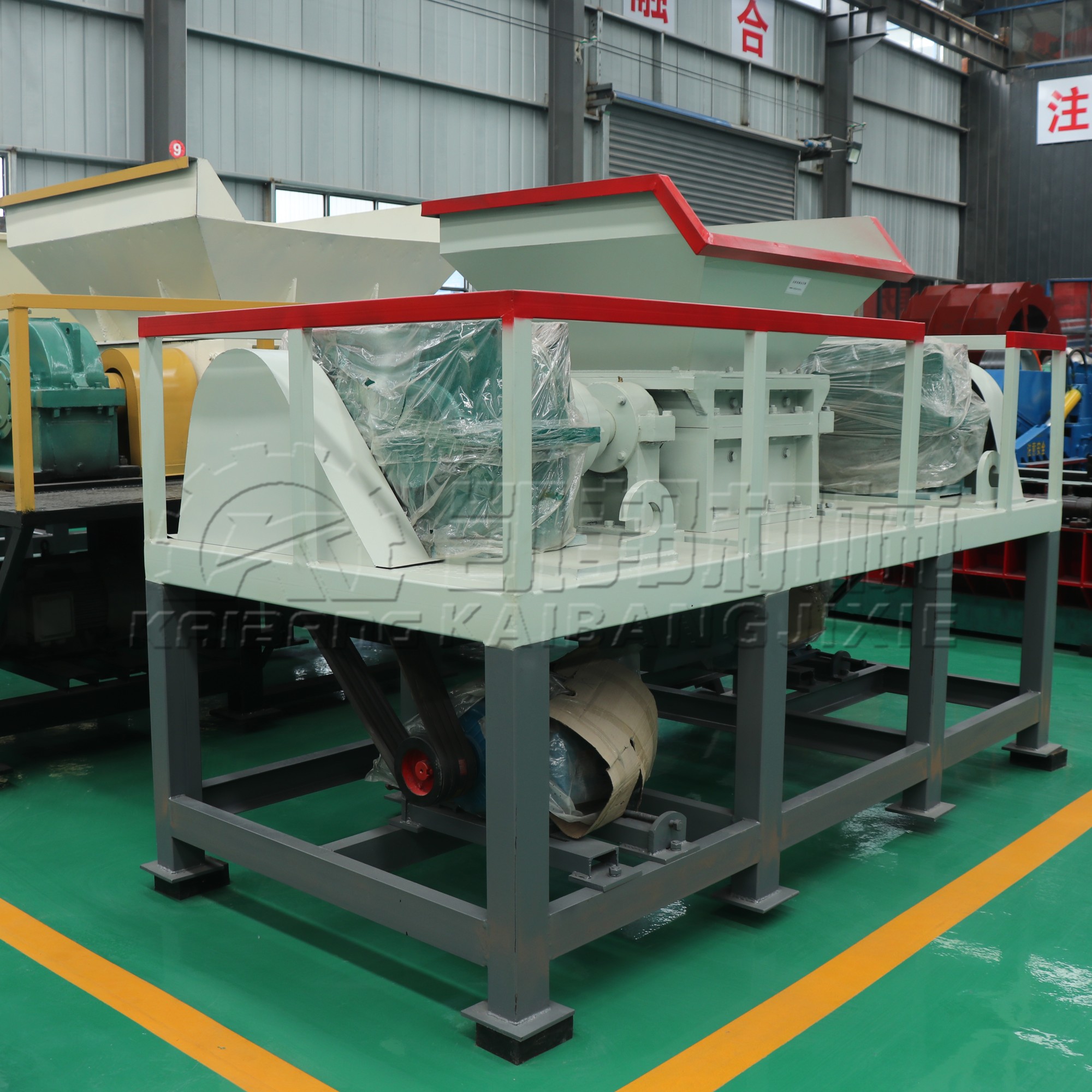

Double Shaft Shredder

Wood Crusher Machine Wood Chipper Shredder for Wooden Pallet

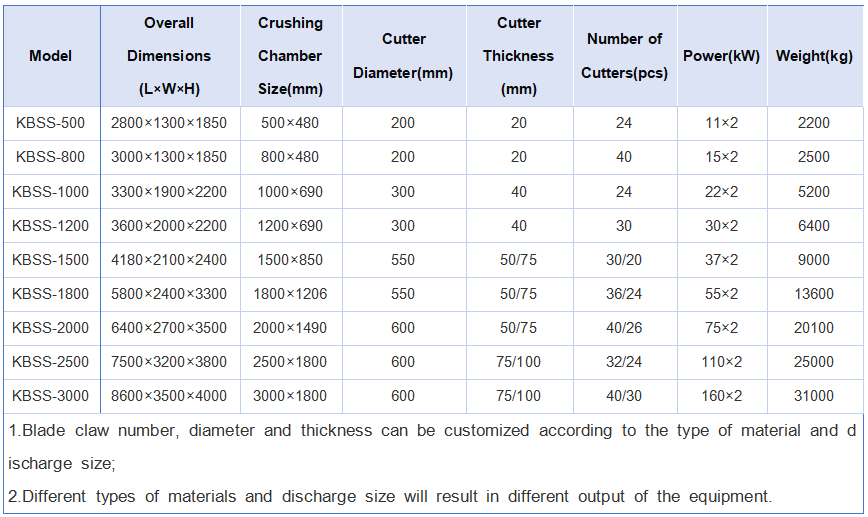

Motor Power: 2*11kw-90kw motors (see parameter table for details)

Production Capacity: 0.6T/h-18T/h (see parameter table for details)

Output Particle Size: Coarse crushing effect, size determined by the number of blade claws

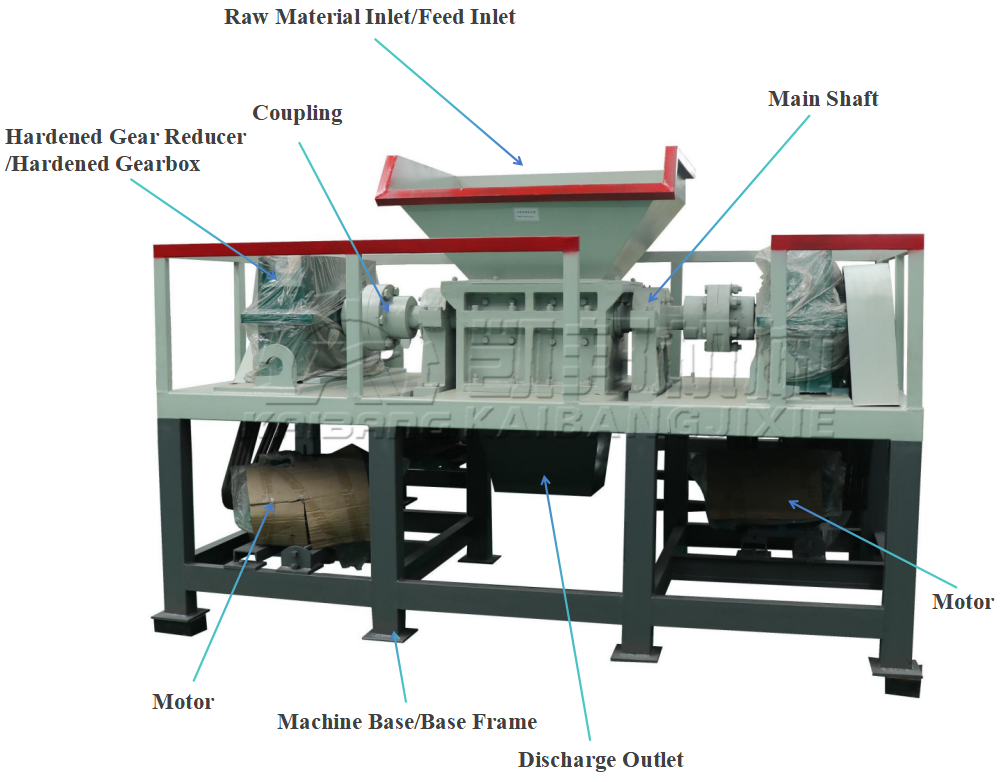

Matching Equipment: Shredder host, power distribution cabinet, reducer*2, motor*2, magnetic separator

Applicable Materials: One-time batch shredding of various wooden materials such as waste wooden boards, wooden pallets, wooden furniture, tree trunks, branches, etc

Wood shredder, also known as shear shredder, reduces materials to a fixed size through the shearing, tearing, and squeezing actions of two blade rollers. After years of research and practice, and based on the actual conditions of domestic customers, Kaibang Machinery has improved and launched a technically mature wood shredder. This equipment provides reliable quality for the efficient shredding, recycling, and volume reduction of wood materials.

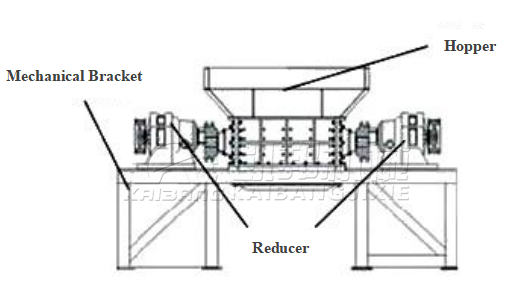

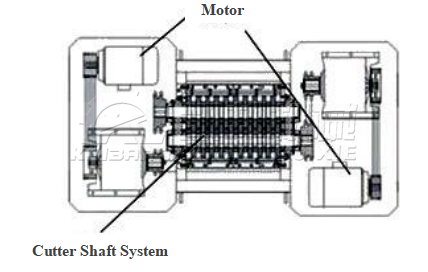

The wood shredder features a large feed inlet, allowing direct input of materials such as wood, branches, and templates into the machine's chamber. The shredding mechanism consists of two blade rollers inside the chamber. Driven by a reducer, the blade rollers rotate, capturing the materials with their blades. Through a combination of compression and shearing, the materials are shredded into small pieces and discharged from the bottom of the machine.

The wood shredder operates on the principle of dual-axis driven shearing, tearing, and compression. Powered by a low-speed, high-torque motor, the rotating blades on the main shaft squeeze and process the materials within the chamber. The gaps between the blades tear the materials into uniformly sized fragments that meet the required specifications.

1. The frame is constructed by welding thick profiles and then precision-machined through boring and milling. Its robust design, reinforced with densely distributed rib plates, not only enhances the strength of the base but also ensures the precise assembly of the bearing seats.

2. The wood shredder has a wide range of applications. In addition to shredding various materials such as wood, bamboo, branches, bark, wooden pallets, and templates, it can also crush paper products like used cartons, textbooks, and books.

3. The equipment is driven by a geared motor, which reduces speed and provides high shredding torque, enabling it to powerfully shred various types of wood.

4. The wood shredder production line can be flexibly equipped with accessories such as conveyor belts to assist operations. Additionally, with advanced manufacturing processes, the system can be customized to provide users with different models of equipment.

5. The wood shredder is a versatile and highly adaptable machine, designed with standardized and modular components, ensuring excellent interchangeability of parts.

6. The blades of the equipment are made from special alloy steel through a unique manufacturing process, offering high wear resistance and exceptional strength.

The wood shredder is widely used for shredding materials such as wood, wooden pallets, solid wood, branches, bark, woodworking scraps, and other large-volume wood waste.

Kaibang Machinery, a manufacturer of wood shredders, offers equipment suitable for various settings, including gardens, forestry, road tree maintenance, and waste recycling stations. The shredder is primarily used for recycling various wood materials and processing branches cut from trees. The shredded material can be used as mulch, garden bedding, organic fertilizer, or mushroom cultivation substrate. Additionally, it can be utilized in the production of high-density boards, particleboards, and in the papermaking industry.

1. It allows for a larger feed size and is suitable for a wide range of materials.

2. The output size is adjustable, and the blades can be customized according to customer requirements.

3. The shredder blades have excellent wear resistance and high strength. With no improper operation, there is no need for blade sharpening or replacement throughout its lifetime, enabling continuous operation and saving significant labor.

4. It operates at low speed, with no dust and zero noise.

5. Capable of 24-hour continuous operation, it boasts high production efficiency and large processing capacity.

<Note: With continuous technological upgrades, all parameters are provided for reference only. In case of any modifications, please refer to the actual product for accuracy.>

Henan Kaibang Machinery Manufacturing Co., Ltd. mainly produces: crushing equipment, drying equipment, forming equipment, pyrolysis reactor equipment, environmental protection equipment, and other complete production line equipment. The company's equipment production, casting and forming, mechanical processing, physical and chemical treatment, to assembly into machines, is fully tracked and inspected by quality testing engineers throughout the process to ensure that users receive high-quality, reliable equipment.

The company has been working hard to build the Kaibang brand for decades, always pursuing excellence, with high-quality staff, strict quality assurance system and perfect after-sales service. We warmly welcome domestic and overseas customers to visit our company for on-site inspection and guidance.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: info@kaibangmachinery.com

Phone: 15638129993

E-mail: +86 15638129993

Whatsapp:86 15638129993

Add: 800 meters east of the intersection of Chuangye Avenue and E23 in Gongyi Industrial Agglomeration Zone, Zhengzhou City, Henan Province, north of the road