Wet Electrostatic Precipitator (WESP)

Effectively control the emission of fine particulate matter

1.PM2.5 and submicron particles

2.Condensates and aerosols

3.Reduce and eliminate opacity

4.Boiler and dryer emissions

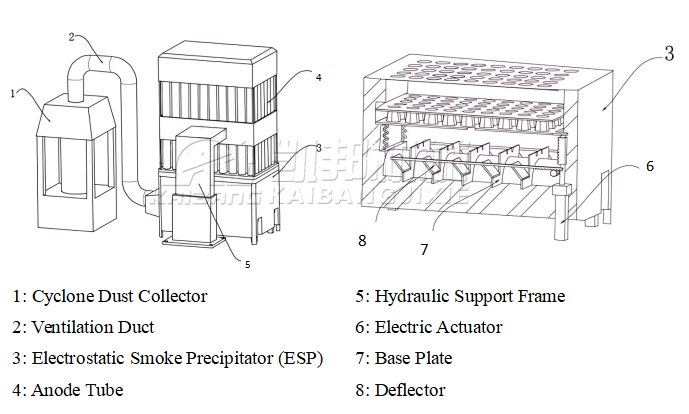

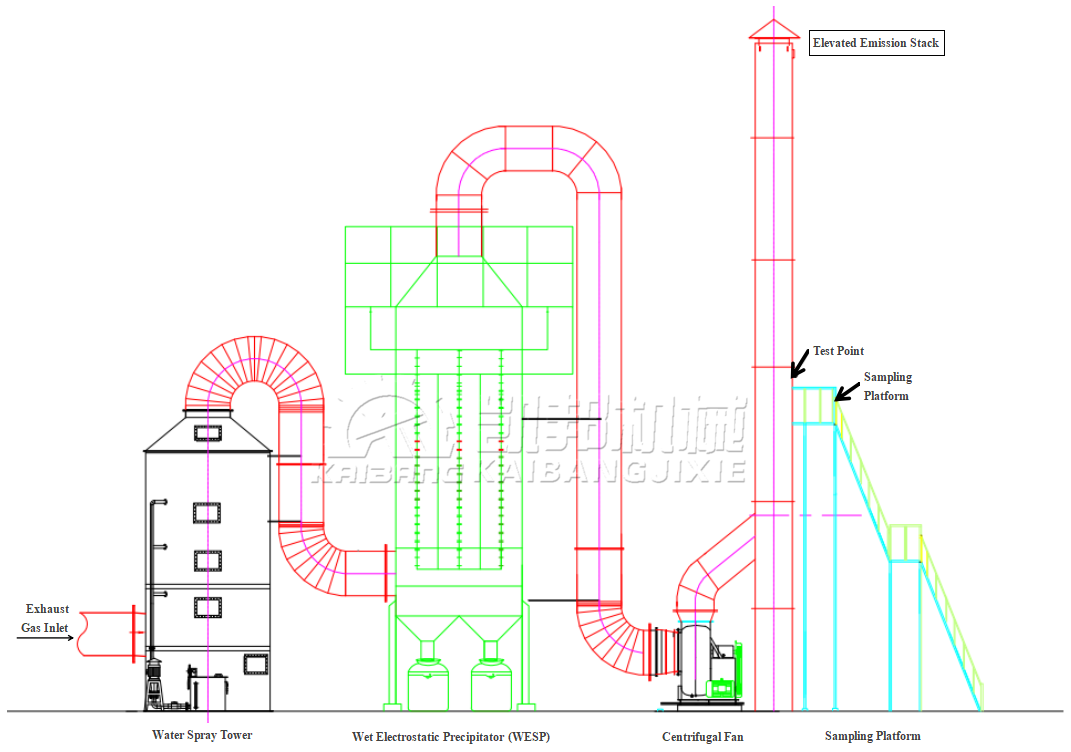

The wet electrostatic precipitator is a device that utilizes high-voltage direct current and electric field force to accelerate the settlement of fine particles in the flue gas onto the surface of the collecting electrode (anode), thereby effectively removing dust and mist from the flue gas.

Regarding the dry ESP, the wet ESP employs electrical forces to eliminate particulate matter (PM) from flue gases. A high-voltage source generates a corona current that charges the PM, causing it to migrate towards the collecting plate. Subsequently, the PM is removed from the plate through the use of flushing water.

1.High-voltage direct current ranging from 0 to 100 kilovolts is introduced into the precipitator, causing the corona electrode suspended within to continuously emit electrons.

2.These electrons ionize some of the gas between the electrodes into positive and negative ions, and particulate matter such as dust and mist becomes charged after colliding with these ions.

3.Based on the principle that like charges repel and opposite charges attract, the charged dust and mist particles move towards opposite electrodes: positive ions move towards the corona electrode, while electrons and negative ions move towards the precipitation electrode.

4.Dust and mist particles dispersed in the gas become charged after colliding with negatively charged ions and move towards the inner wall of the precipitation electrode under the action of electric field force. Some dust particles fall down the wall due to their own weight and enter the lower chamber of the electrical mist eliminator. Due to the strong adhesiveness of gypsum, which easily adheres to the pipe wall, a single-tube, single-flush rinsing device has been designed with a fixed rinsing time to address the issue of gypsum fouling on the anode tube and cathode wire, thereby achieving flue gas purification.

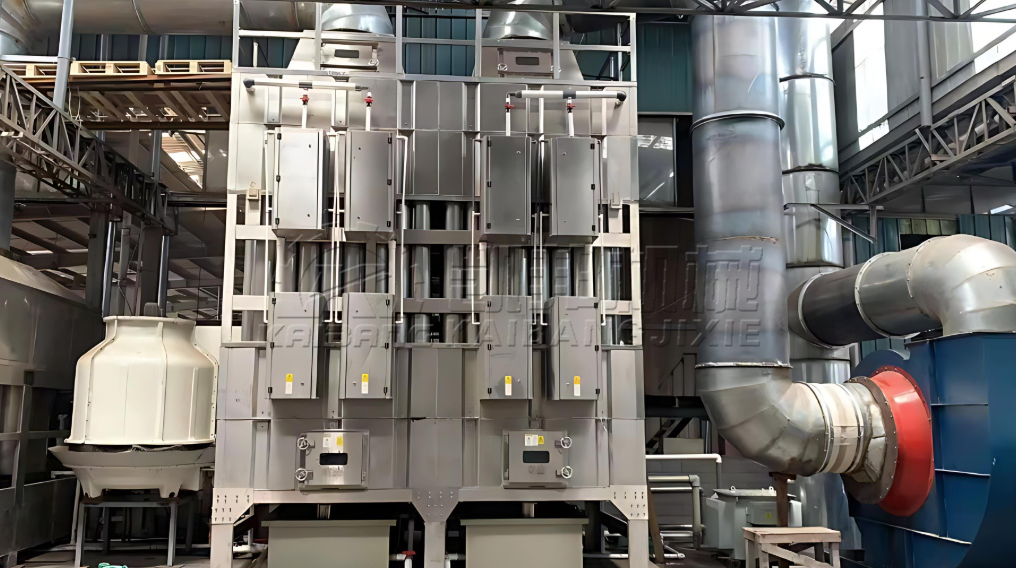

Materials: The equipment is manufactured using materials such as stainless steel, fiberglass reinforced plastic (FRP), and carbon steel, ensuring corrosion resistance and long-term stability of the device.

Components: It is equipped with internal components including cathode rods, anode plate assemblies, insulation boxes, and a cleaning water system, which guarantee the normal and efficient operation of the equipment.

Sediment Collection Chamber: Located beneath the main body housing, this chamber features observation windows and a cleaning water system for convenient monitoring and cleaning.

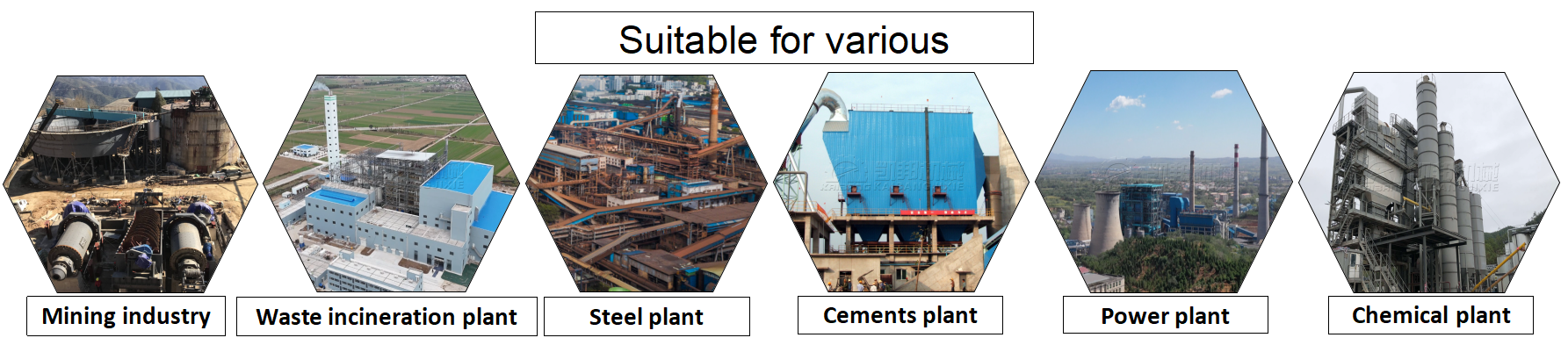

Wet electrostatic precipitators (WESPs) and electrostatic smoke abatement devices are applicable in a wide range of industrial sectors, including metals, cement, building materials, ceramics, electronics, chemicals, casting, metallurgy, power generation, machinery processing, and non-ferrous metals, specifically for dust purification, smoke removal, and fog clearance.

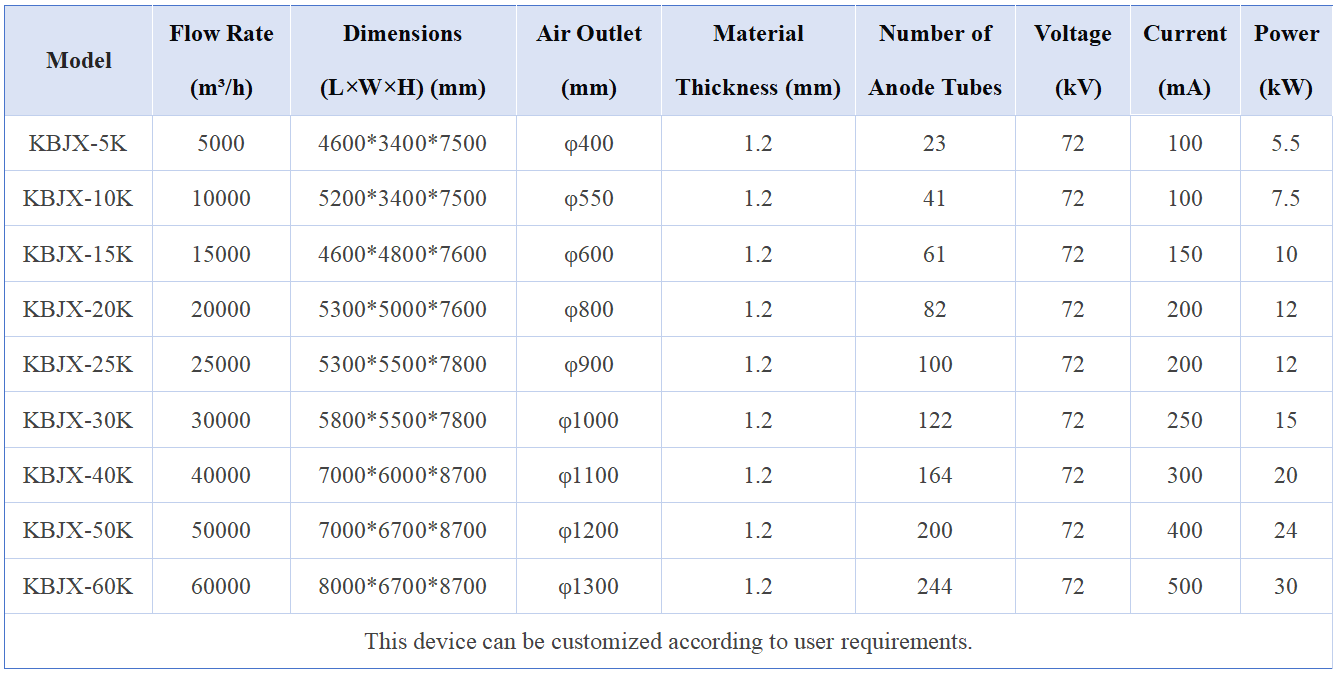

Note: The selection of wet electrostatic smoke abatement devices must be customized based on the volume flow rate and concentration of the exhaust gases generated. The outer casing can be fabricated using materials such as carbon steel, polypropylene (PP) plates, and stainless steel (grades 201, 304, 316).

1.High-Efficiency Mist Removal and Wide Range of Applicability: This equipment boasts a mist removal efficiency of over 95%, effectively eliminating gaseous suspended particles and mist droplets ranging from 0.01 to 100 micrometers. Additionally, it demonstrates a wide range of applicability for smoke and fog, with mature and reliable technology, making it suitable for various industrial and environmental protection scenarios.

2.Durability and Low Maintenance Costs: The equipment is manufactured from corrosion-resistant and non-abrasive materials, ensuring a long service life. Electrode maintenance is simple and straightforward, guaranteeing stable long-term operation. Moreover, with low resistance, energy consumption, and noise levels, it further reduces operational costs and maintenance complexity.

3.Unique Collection Capability and High-Efficiency Dust Removal:Due to the good conductivity of mist droplets formed by the interaction between dust and water, this equipment can collect viscous and high-specific-resistance dust that is difficult to handle by electrostatic precipitators. At the same time, it eliminates the need for rapping devices, adopting a single-tube single-flush system to prevent secondary flying and potential transmission device failures. Furthermore, it exhibits high efficiency in mist and dust removal, particularly skilled in capturing fine dust particles, mist droplets, aerosols, metal particles, and acid mists.

4.Advanced Control and Efficient Electric Field Driving: When equipped with microcomputer-controlled power supplies and new-type discharge electrodes, the driving speed of various pollutants in flue gas within the electric field is significantly increased, reaching above 0.1m/s, with some even reaching 0.19m/s, further enhancing the purification efficiency and performance of the equipment.

<Note: With continuous technological upgrades, all parameters are provided for reference only. In case of any modifications, please refer to the actual product for accuracy. >

Henan Kaibang Machinery Manufacturing Co., Ltd. mainly produces: crushing equipment, drying equipment, forming equipment, pyrolysis reactor equipment, environmental protection equipment, and other complete production line equipment. The company's equipment production, casting and forming, mechanical processing, physical and chemical treatment, to assembly into machines, is fully tracked and inspected by quality testing engineers throughout the process to ensure that users receive high-quality, reliable equipment.

The company has been working hard to build the Kaibang brand for decades, always pursuing excellence, with high-quality staff, strict quality assurance system and perfect after-sales service. We warmly welcome domestic and overseas customers to visit our company for on-site inspection and guidance.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: info@kaibangmachinery.com

Phone: 15638129993

E-mail: +86 15638129993

Whatsapp:86 15638129993

Add: 800 meters east of the intersection of Chuangye Avenue and E23 in Gongyi Industrial Agglomeration Zone, Zhengzhou City, Henan Province, north of the road