Hammer mill wood chip crusher

Hammer Mill for Wood & Feed Pellet Processing

Brand: KAIBANG

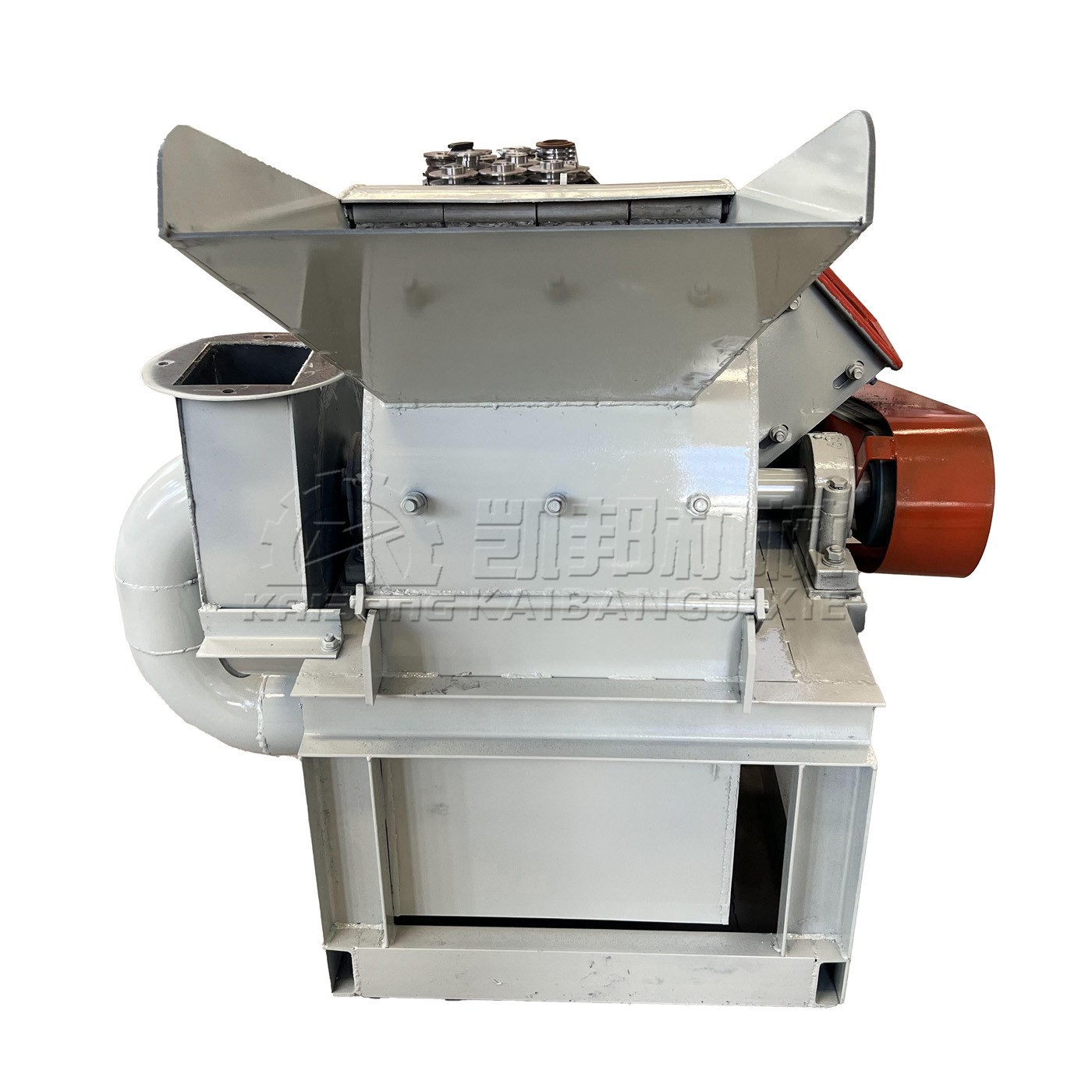

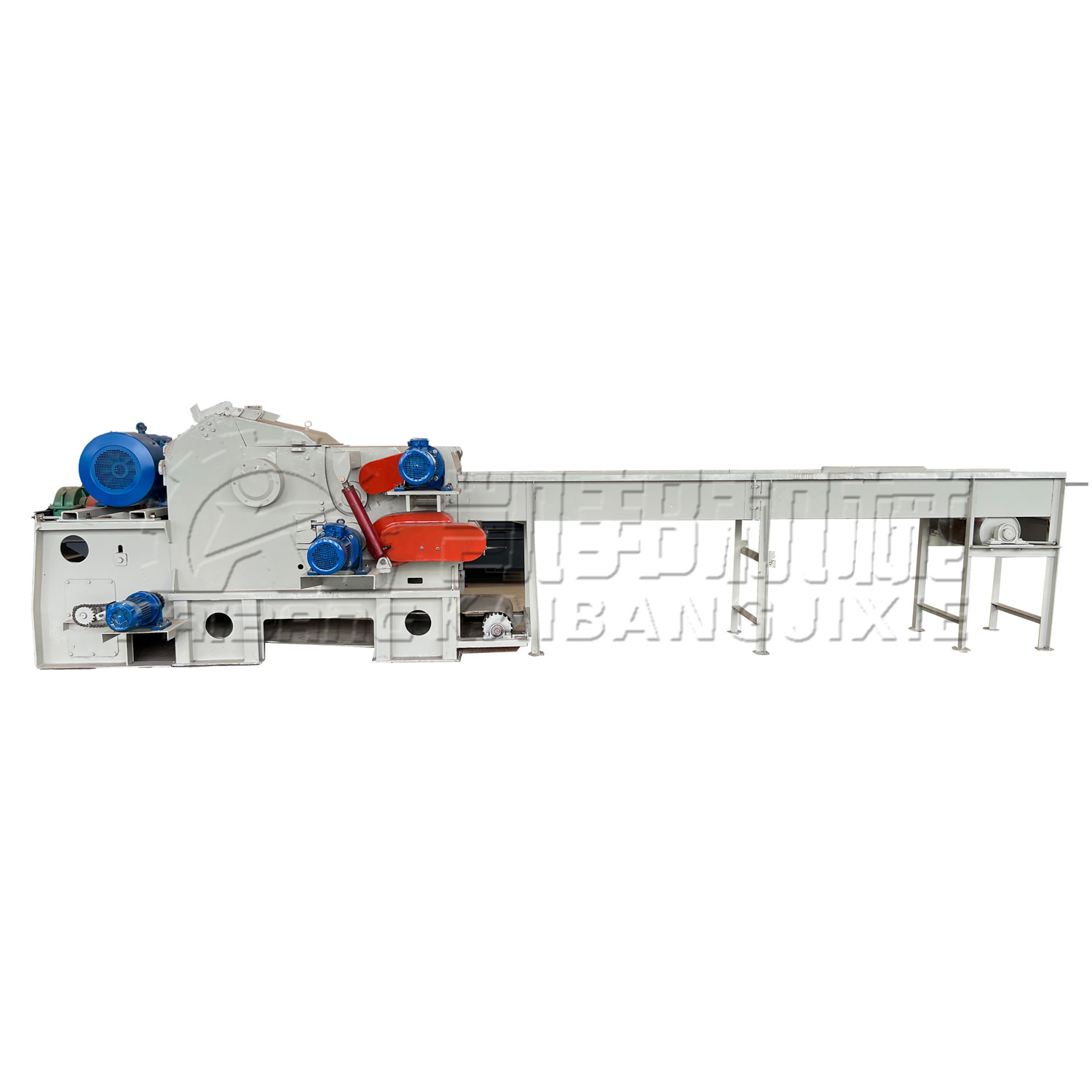

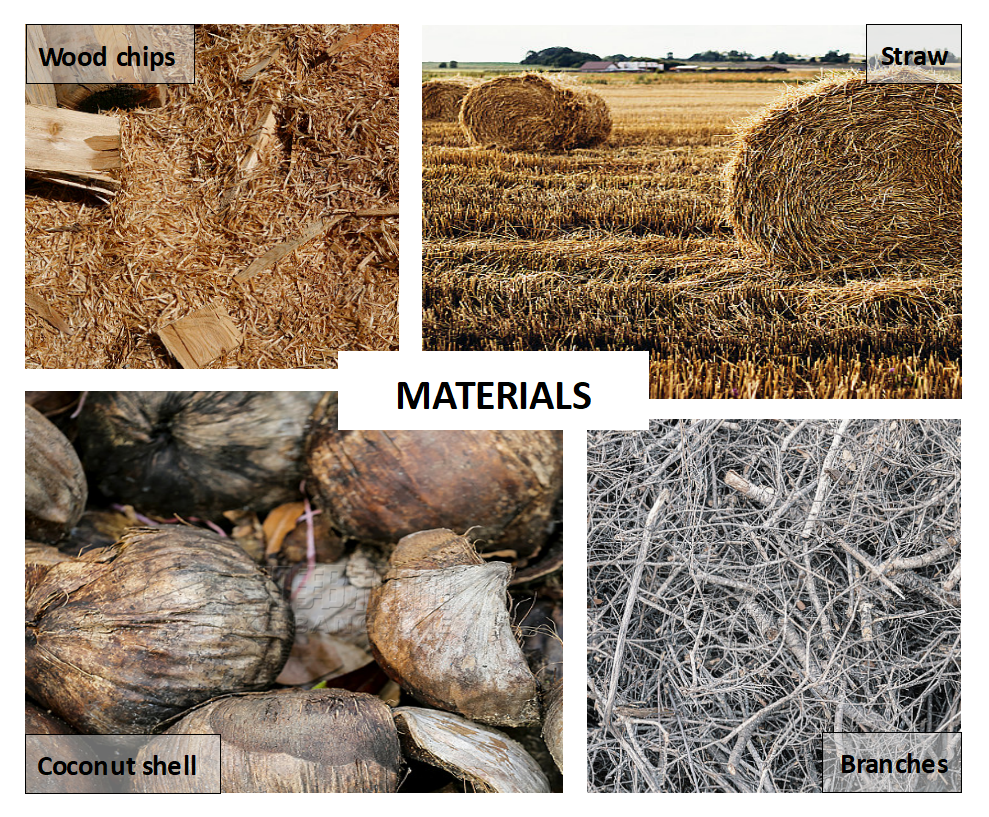

The hammer mill, also known as the wood chipper, is capable of processing raw materials like wood, branches, miscellaneous wood, and boards into sawdust in just one pass. It boasts various advantages, including low investment, low energy consumption, high productivity, favorable economic benefits, and ease of use and maintenance. It serves as a specialized device for producing sawdust particles that are used in the cultivation of edible mushrooms or in the manufacture of particleboard, sawdust board, and high-density board.

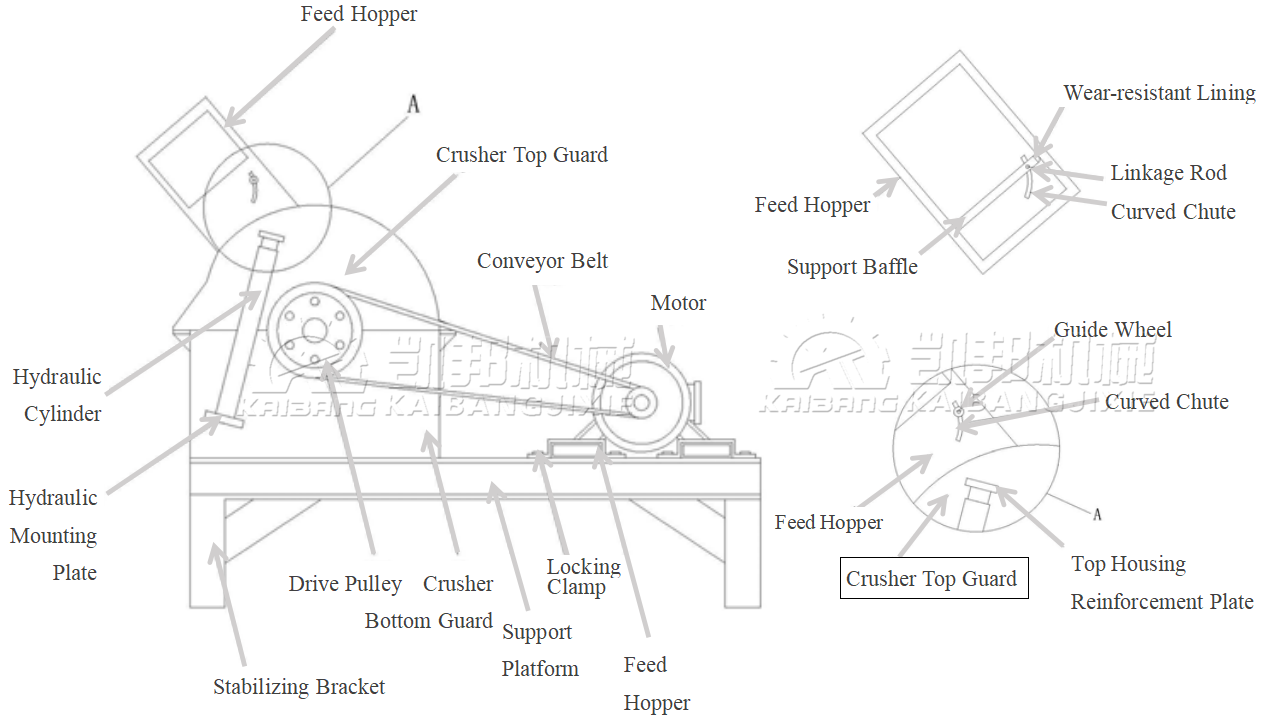

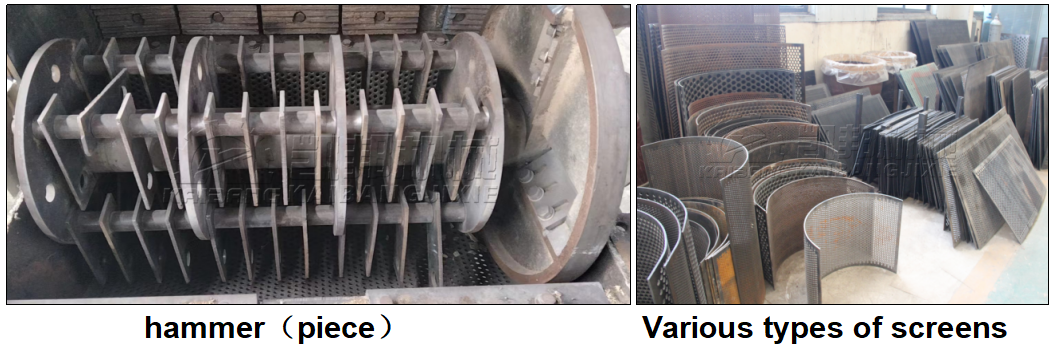

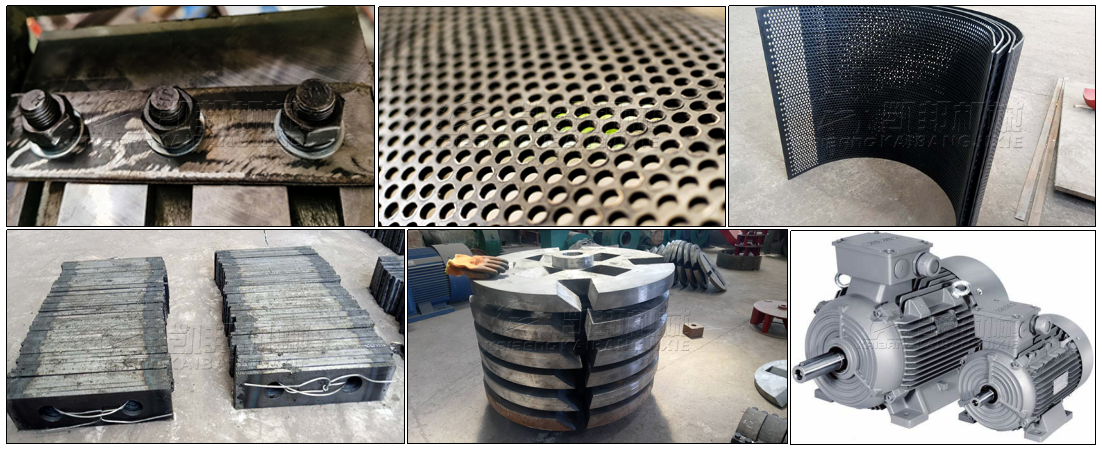

Structure: The hammer mill is currently the most widely applied type of crusher, boasting significant usage in electrical products and excellent versatility. Its structure is comprised of three main parts: the feed inlet, the crushing chamber (incorporating the rotor, hammers, screen, and tooth plate), and the discharge section (consisting of the fan, dust collector drum, cyclone separator, and dust bag).

Principle: The hammer crusher operates mainly by utilizing impact force to crush materials. In the crushing process, materials enter the crusher and are struck by high-speed rotating hammers, resulting in their shattering. The shattered materials, gaining kinetic energy from the hammer impacts, hit the screen at high speeds. Meanwhile, rapid collisions among the materials themselves lead to further fragmentation at multiple points. When the materials impact the screen, those smaller than the diameter of the screen holes are discharged, while larger pieces undergo continued impacting, grinding, pressing, and crushing by the hammers until they meet the specified requirements and are subsequently discharged.

1.Materials within the crushing chamber undergo comprehensive and efficient coarse and fine crushing.

2.High throughput, low energy consumption, high efficiency, and consistent fine output.

3.Rational structure, customizable options, automatic feeding, and reliable safety features.

The hammer mill is suitable for processing all soft and small-sized materials. For example, it can be used to crush coconut shells, particleboard, wood chips, and similar items. Furthermore, it is capable of pulverizing small twigs, slender branches, cornstalks, thin panels, as well as medical materials.

After pulverizing, final product can be controlled within 3 ~ 20mm.

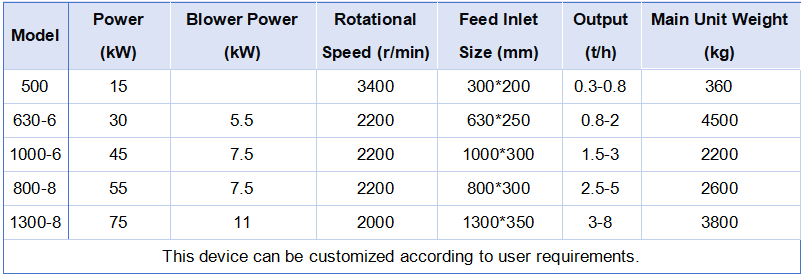

<Note: With continuous technological upgrades, all parameters are provided for reference only. In case of any modifications, please refer to the actual product for accuracy.>

Henan Kaibang Machinery Manufacturing Co., Ltd. mainly produces: crushing equipment, drying equipment, forming equipment, pyrolysis reactor equipment, environmental protection equipment, and other complete production line equipment. The company's equipment production, casting and forming, mechanical processing, physical and chemical treatment, to assembly into machines, is fully tracked and inspected by quality testing engineers throughout the process to ensure that users receive high-quality, reliable equipment.

The company has been working hard to build the Kaibang brand for decades, always pursuing excellence, with high-quality staff, strict quality assurance system and perfect after-sales service. We warmly welcome domestic and overseas customers to visit our company for on-site inspection and guidance.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: info@kaibangmachinery.com

Phone: 15638129993

E-mail: +86 15638129993

Whatsapp:86 15638129993

Add: 800 meters east of the intersection of Chuangye Avenue and E23 in Gongyi Industrial Agglomeration Zone, Zhengzhou City, Henan Province, north of the road