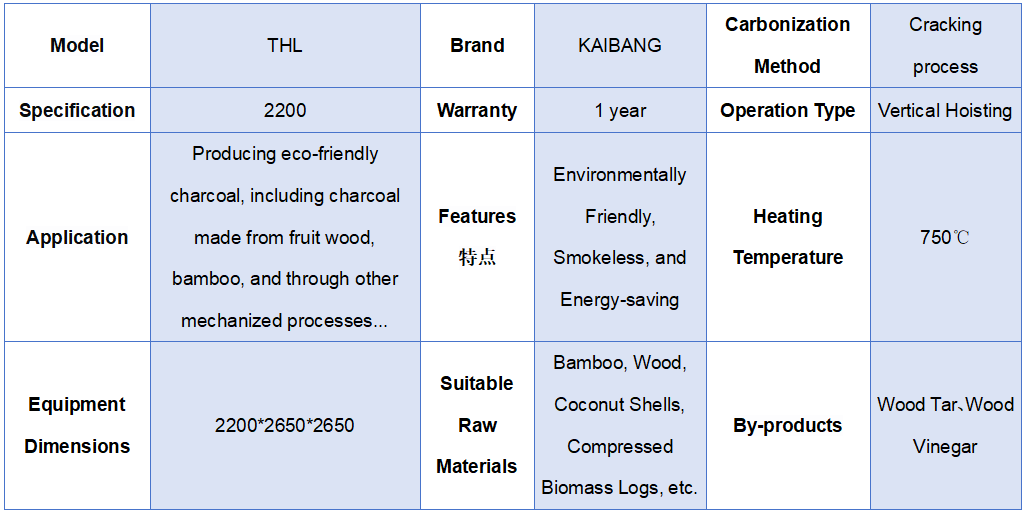

Vertical Carbonization Furnace

Brand: KAIBANG

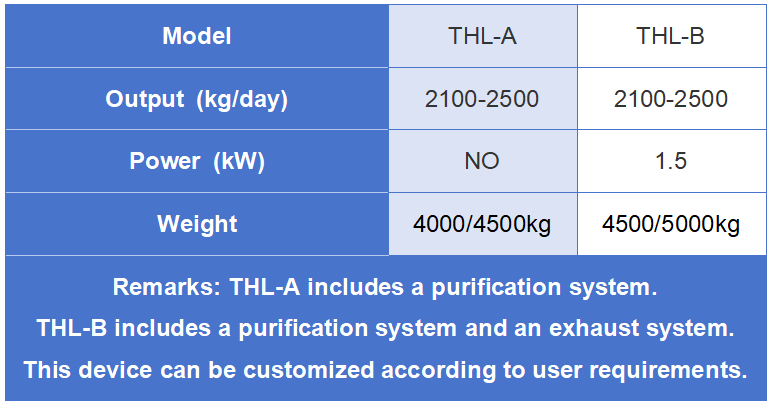

Capacity:950kg/day(The output varies depending on the material)

Carbonizing time: 30h(Carbonization time varies depending on the material)

Temperature: 450-850℃(Carbonization temperature varies according to the material of the equipment)

Overview

The vertical carbonization furnace is used to convert biomass materials such as wood, coconut shells into charcoal through carbonization, which has fast carbonization, high carbonization rate, no smoke. The carbonization furnace is environment friendly and efficient and ideal equipment for making high quality charcoal. It is is widely used in agriculture, industry and daily life.

The structure of the vertical carbonization furnace comprises multiple components, including the furnace body, furnace cover, heating chamber, and exhaust pipe. Nested cleverly within the furnace chamber of the furnace body is a carbonization liner (or basket), atop which is securely fitted a tight cover. The upper edge of this carbonization liner features a downwardly folded annular flange that mates precisely and securely with a fixed annular sealing ring positioned on the upper interior of the furnace chamber, thereby ensuring a tight seal during the carbonization process.

Moreover, lifting ears are securely mounted on the side wall of the carbonization liner, the surface of its upper cover, as well as on the furnace cover. These lifting ears not only facilitate easy lifting and handling during the carbonization process but also reinforce the overall stability and practicality of the entire carbonization furnace structure.

The carbonization furnace and combustion chamber are designed separately, allowing the equipment to operate continuously by utilizing flexibly installable and removable carbonization liners. A single furnace body can accommodate multiple carbonization liners. When it comes to replacing a carbonization liner, there is no need for cumbersome preheating steps. The cooling process of the carbonization liner is entirely separate from the furnace body, which greatly enhances work efficiency and ensures superior sealing. This equipment is not only structurally simple and innovative but also straightforward and quick to operate in practice, being safe and reliable, and offering great convenience to users.

Vertical Chamber: The main body of the Vertical carbonization furnace is a tall, cylindrical chamber where the carbonization process takes place vertically. This chamber is made of heat-resistant materials like steel.

Heating System: Heat is provided to the chamber to initiate the pyrolysis process.

Airflow Control System: To ensure proper carbonization, the carbonization furnace needs to control the airflow. In the vertical carbonization furnace, airflow is often regulated through vents or dampers located at different levels of the chamber. This allows for the adjustment of oxygen levels inside the chamber to optimize the pyrolysis process.

Collection and Exhaust System: As the biomass undergoes pyrolysis, volatile gases and other byproducts are released. These gases need to be collected and either utilized as a fuel source or properly disposed of. The exhaust system can remove these gases safely.

Feeding System: Biomass materials are fed into the top of the carbonization furnace chamber through a feeding system. This system may consist of a hopper or conveyor belt to continuously introduce the raw material.

Discharge System: Once the carbonization process is complete, the finished charcoal needs to be removed from the carbonization furnace. A discharge system at the bottom of the chamber allows for the removal of the finished charcoal.

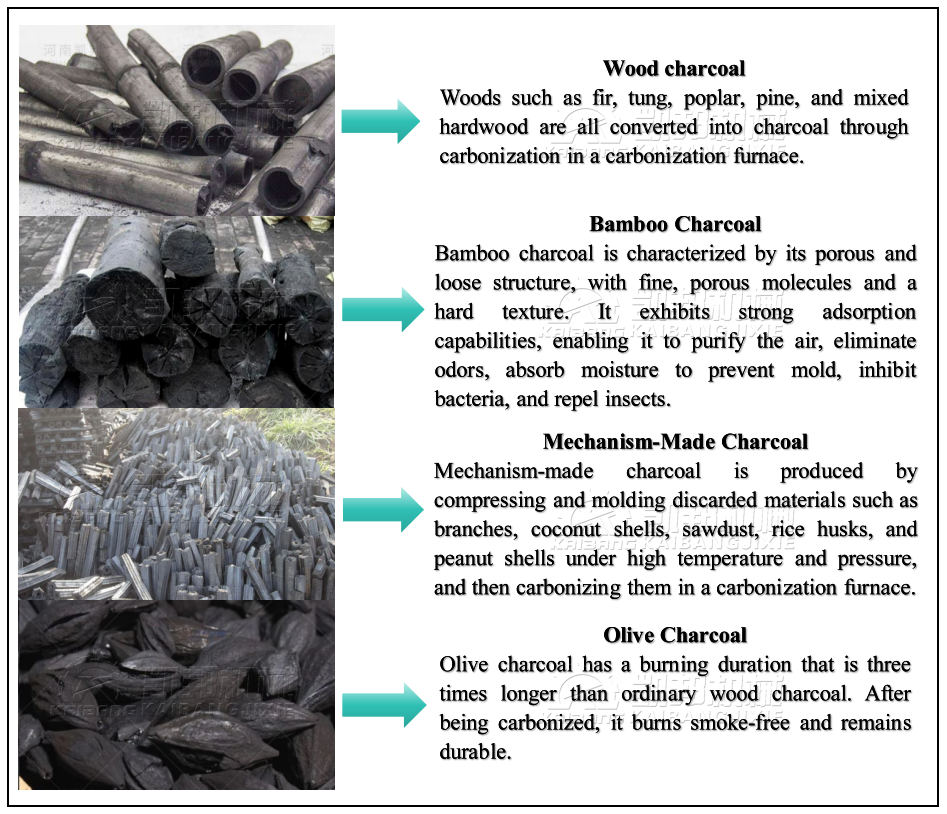

Adaptable to multiple materials

Carbonization of Various Wooden Materials

Carbonization of Various Wooden Materials

We are capable of carbonizing raw wood and mechanism-made charcoal, achieving high yield rates and excellent quality.

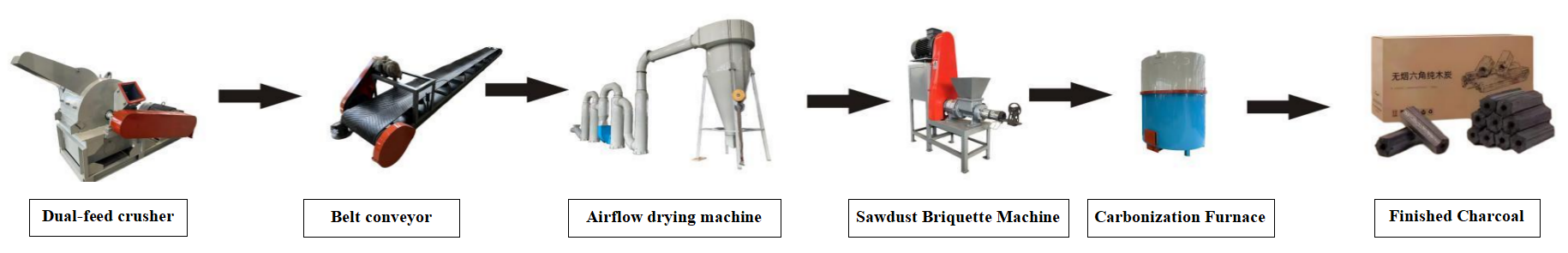

1.Open the cover of the furnace body.

2.Lift out the furnace liner and securely place it in the designated area for installing the core rods.

3.Open the lid of the furnace liner and tilt it for placement. During the carbonization process, wood charcoal takes 6 hours per batch to carbonize and 10 hours to cool, whereas machine-made charcoal takes 7 hours per batch to carbonize and likewise requires 10 hours to cool. Although the cooling time for both types of charcoal is the same, the carbonization time for machine-made charcoal is slightly longer. This equipment is easy to operate, features excellent safety performance, and boasts high production efficiency, making it an ideal energy-saving device for continuous production of charcoal, gas, oil, and coal.

4.After completing the rod installation, close the lid of the furnace liner and lift the liner back into the furnace body.

5.Open the three smoke outlets of the furnace body in sequence, ensure the furnace liner lid is tightly closed, and spread some sand around the lid for sealing purposes. Then, begin the carbonization process.

1. Vertical Design: The vertical orientation allows for efficient heat distribution and uniform carbonization of biomass materials throughout the chamber.

2. Compact Footprint: Vertical carbonization furnace has a smaller footprint compared to horizontal models, making them suitable for installations where space is limited.

3. Efficient and Energy Saving: The vertical carbonization furnace incorporates energy-efficient designs and insulation materials to minimize heat loss and reduce energy consumption during operation to achieve high-efficiency utilization of the carbonization process.

4. Short Production Cycle: Using three internal furnaces for alternating carbonization and separate external natural cooling, the entire production cycle is directly shortened by 2/3, which greatly improves production efficiency and saves production time.

5. No Pollution: Zero smoke and dust emissions. The furnace is equipped with a complete closed purification system. The entire carbonization process has no emissions, clean production and environmental protection.

6. Automated Control System: Advanced model can adjust various parameters, ensuring consistent and high-quality charcoal production.

Charcoal Manufacturers: Vertical carbonization furnace is the main equipment of charcoal manufacturers. It is commonly used to convert biomass feedstocks such as wood chips, sawdust, coconut shells, and rice husks into carbonized charcoal. These charcoals can be used for various purposes such as barbecues, stove heating, cooking and industrial production.

Rural Energy Utilization: In rural areas, vertical carbonization furnaces can provide local residents with renewable energy for cooking, heating, lighting and other needs. Carbonized charcoal can be also used to improve soil, increase soil fertility, and promote crop growth.

Industrial Use: In addition to charcoal production, vertical carbonization furnace can also be used to produce other carbonization products, such as activated carbon. Activated carbon is widely used in water treatment, air purification, chemical industry, medicine and other fields.

<Note: With continuous technological upgrades, all parameters are provided for reference only. In case of any modifications, please refer to the actual product for accuracy.>

Henan Kaibang Machinery Manufacturing Co., Ltd. mainly produces: crushing equipment, drying equipment, forming equipment, pyrolysis reactor equipment, environmental protection equipment, and other complete production line equipment. The company's equipment production, casting and forming, mechanical processing, physical and chemical treatment, to assembly into machines, is fully tracked and inspected by quality testing engineers throughout the process to ensure that users receive high-quality, reliable equipment.

The company has been working hard to build the Kaibang brand for decades, always pursuing excellence, with high-quality staff, strict quality assurance system and perfect after-sales service. We warmly welcome domestic and overseas customers to visit our company for on-site inspection and guidance.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: info@kaibangmachinery.com

Phone: 15638129993

E-mail: +86 15638129993

Whatsapp:86 15638129993

Add: 800 meters east of the intersection of Chuangye Avenue and E23 in Gongyi Industrial Agglomeration Zone, Zhengzhou City, Henan Province, north of the road