Honeycomb Charcoal Briquettes Machine

Honeycomb Coal Briquette Machine | Charcoal Press Machine

Brand: Kaibang

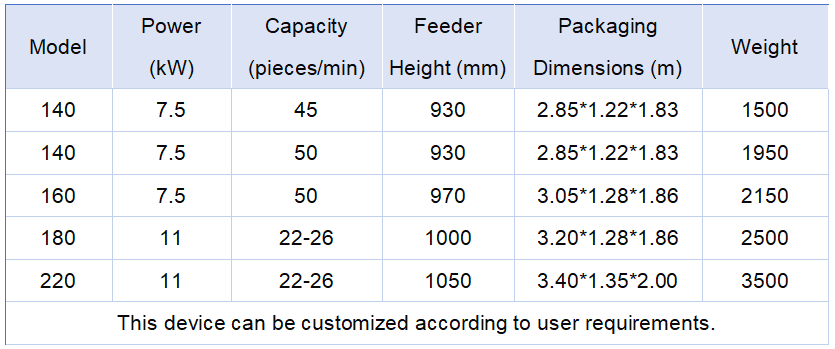

Model: 140

Power: 7.5kw

Capacity: 45 Pcs/time

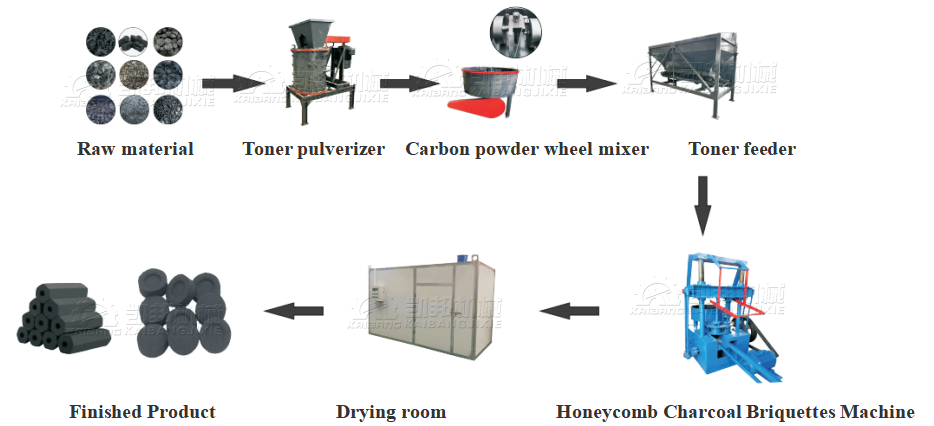

The honeycomb charcoal press machine, also known as the honeycomb coal press or coal briquette press, uses powdered coal as raw material. After mixing, pressing, and forming, it produces honeycomb-shaped or cylindrical coal lumps. This machine is multifunctional; by changing the mold, it can produce coal lumps of various shapes and sizes, such as cylindrical, square, rod-shaped, and flower-shaped, significantly expanding its capabilities. We can also design and manufacture custom molds according to customer requirements.

Suitable for crushing medium hardness materials, such as cement, chemical industry, electric power, metallurgy, building materials such as limestone, slag, coke, coal and other refractory materials and other industrial sectors.

The honeycomb briquette machine is mainly composed of several core components: the feeding hopper, compression chamber, mold, and hydraulic system. Its working principle is as follows: First, raw materials such as coal powder or charcoal are fed into the machine's hopper. Then, the materials are conveyed to the compression chamber, where they are strongly compressed under high pressure provided by the hydraulic system. The mold shapes the briquettes into a specific form with a honeycomb structure. This unique honeycomb design not only enhances airflow within the briquettes but also significantly improves combustion efficiency, making it a highly effective and environmentally friendly fuel.

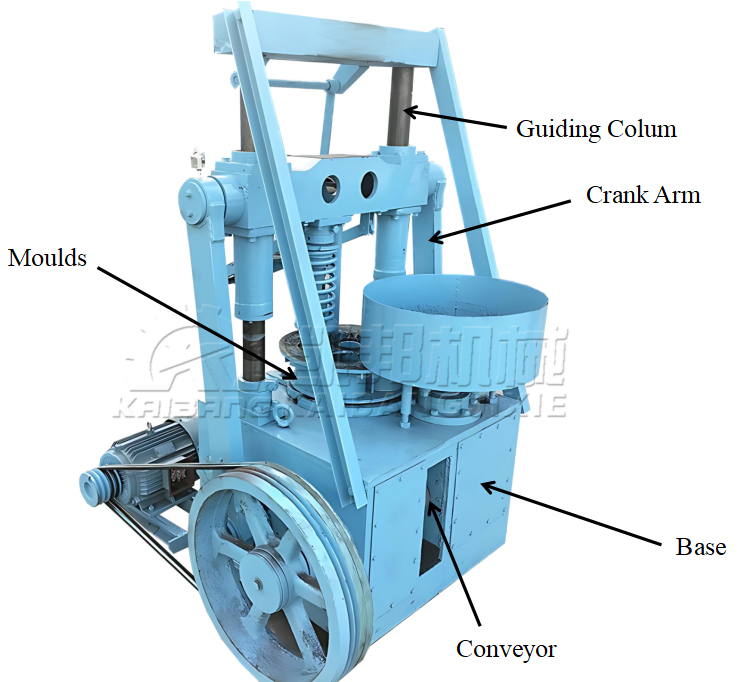

The honeycomb briquetting machine features a simple yet integrated structure,with five major systems functioning in coordinated operation:

Frame System: Constructed with a bedplate and reinforced base,this forms the machine's structural foundation by providing rigid support to all components.

Transmission System: Comprising an electric motor,pulley assembly,gear trains,and drive shafts. The motor drives the pulley to rotate the gear shaft,which transmits torque through a two-stage gear reduction to the main drive shaft for precise power delivery.

Feeding Mechanism: Equipped with a rotating shaft,hopper,and agitator. Axial gear transmission enables uniform mixing and delivery of pulverized coal into the molding cylinder,ensuring consistent material distribution.

Punching Assembly: This precision system consists of four sliding rods,movable crossbeam,punch head,punch holder,dynamic pressure plate,movable die base,and compression springs. The synchronized movement of these components ensures accurate briquette formation.

Conveying System: Integrated with a conveyor frame,idler pulley,support brackets,and adjustable belt. The belt operates in tandem with machine cycles to eject finished briquettes. Turnbuckle screws on the frame allow precise adjustment of belt tension for optimal performance.

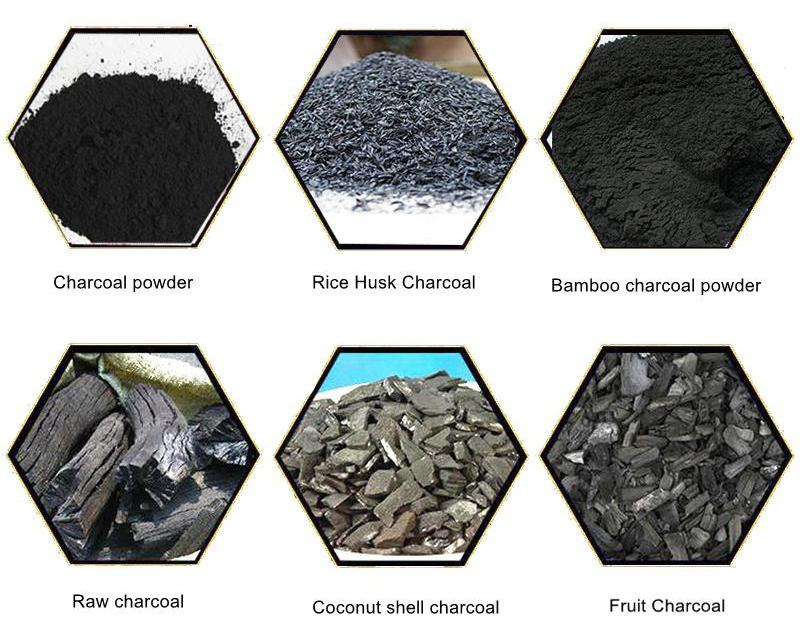

Applicable raw materials

Coal powder, coal dust, coal ash, charcoal powder, coal gangue, middlings, brown coal, breeze, coke powder, furnance slag, etc.

The briquettes produced by the honeycomb coal and charcoal briquette machine have the following characteristics in terms of shape and output:

Shape: The briquettes can be made in various shapes, including round, cylindrical, square, rectangular, polygonal, hexagonal, and fan-shaped. Custom shapes are also available based on your specific requirements.

Size: The final size of the briquettes depends on the shape and the machine's mold. You can also determine the size within a certain range.

Features: The briquettes are characterized by high density, easy ignition, long burning time, and the advantages of being non-toxic and smokeless.

Final Products from Honeycomb Charcoal Briquettes Machine

The machine has adjustable molds and a single machine is compatible with multiple mold types. Changing molds is designed for convenience, and even if you have specific ideas, we can fabricate ideal molds tailored to your needs.

The honeycomb briquettes are formed through pre-compression, resulting in high-density finished products that are resistant to breaking.

The machine is of high quality, durable, and requires no additional components, making maintenance very convenient and extending its service life. Maintenance is straightforward: simply lubricate the internal gears and bearings of the conveyor belt weekly. Additionally, perform lubrication maintenance every 10 to 15 days.

<Note: With continuous technological upgrades, all parameters are provided for reference only. In case of any modifications, please refer to the actual product for accuracy. >

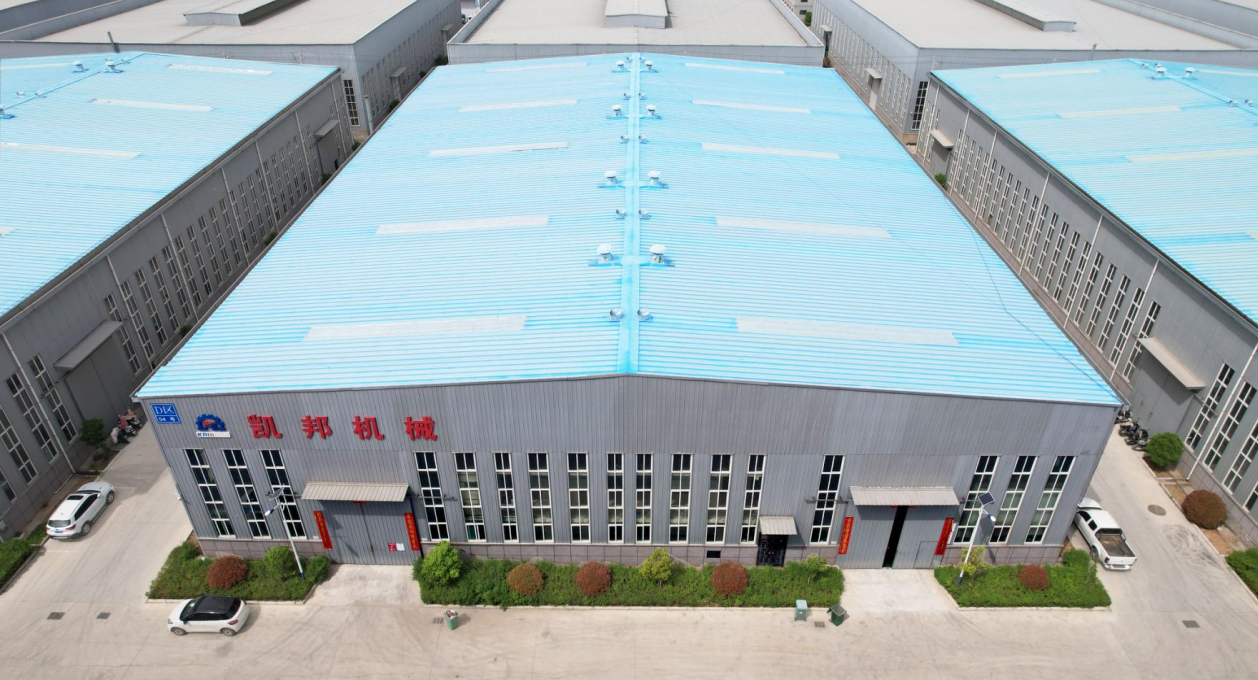

Henan Kaibang Machinery Manufacturing Co., Ltd. mainly produces: crushing equipment, drying equipment, forming equipment, pyrolysis reactor equipment, environmental protection equipment, and other complete production line equipment. The company's equipment production, casting and forming, mechanical processing, physical and chemical treatment, to assembly into machines, is fully tracked and inspected by quality testing engineers throughout the process to ensure that users receive high-quality, reliable equipment.

The company has been working hard to build the Kaibang brand for decades, always pursuing excellence, with high-quality staff, strict quality assurance system and perfect after-sales service. We warmly welcome domestic and overseas customers to visit our company for on-site inspection and guidance.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: info@kaibangmachinery.com

Phone: 15638129993

E-mail: +86 15638129993

Whatsapp:86 15638129993

Add: 800 meters east of the intersection of Chuangye Avenue and E23 in Gongyi Industrial Agglomeration Zone, Zhengzhou City, Henan Province, north of the road