Box-type Carbonization Furnace

Box-type Carbonization Furnace

Capacity:1-1.3t/day (The output varies depending on the material)

Carbonizing time:More than 30 hours(Carbonization time varies depending on the material)

Temperature: 450-850℃ (Carbonization temperature varies according to the material of the equipment)

The box-type carbonization furnace consists of a screw conveyor batching device, a furnace body, an air-cooling unit, a water-cooling unit, and an outlet bin, installed sequentially from top to bottom. The screw conveyor batching device is equipped with an inlet bin. The furnace chamber within the furnace body is partitioned into a preheating zone, a carbonization zone, and a cooling zone by baffles. The preheating zone of the furnace body is fitted with a mixed gas recovery pipe, the carbonization zone with a dry distillation gas recovery pipe, and the cooling zone with a cooled mixed gas recovery pipe. The air-cooling unit has an air inlet and an air outlet on opposite sides, while the water-cooling unit has a water inlet and a water outlet on opposite sides. The outlet bin is equipped with spray nozzles on both sides and a screw discharge device at the bottom. When biomass pellets are introduced into this equipment, they pass through each unit from top to bottom, completing the carbonization process of biomass. This product effectively treats waste biomass, recycles and reuses renewable resources, achieves waste utilization, and is energy-efficient and environmentally friendly.

The biomass box-type carbonization furnace consists of a furnace body, a carbonization chamber, a combustion chamber, and a carbon discharge mechanism. The combustion chamber is equipped with a grate and a combustible gas combustion assembly. The furnace body features a thermal insulation layer, which is a double-layer structure filled with thermal insulation materials. An electric airflow control valve is installed on the air inlet pipeline. A thermocouple is mounted inside the furnace body, and the thermocouple, blower, and electric airflow control valve on the air inlet pipeline are all connected to a temperature control system. The lower end of the carbonization chamber is fitted with a carbon outlet that connects to a carbon discharge machine, and the lower end of the carbonization chamber has a water-jacketed structure.

1.Box-type carbonization furnaces have a wide range of applications, utilize relatively advanced technology, and are still in the process of development. They are designed to be lightweight and easily movable, featuring a simple yet aesthetically pleasing appearance. These furnaces are environmentally friendly, efficient, labor-saving, and can be quickly installed and put into operation.

2.Box-type carbonization furnaces can extract charcoal at relatively high temperatures, which shortens the cooling time and production cycle, thereby increasing the "monthly output."

3.Box-type carbonization furnaces do not burn directly outside the furnace, which helps protect the furnace structure, significantly extends its service life, and reduces maintenance workload.

4.Box-type carbonization furnaces start at a higher temperature, allowing carbonization to proceed without the need for ignition. This shortens the carbonization time, reduces "charcoal waste," and increases both the "charcoal yield" and "monthly output."

5.With better cooling performance, box-type carbonization furnaces are suitable for producing "medium-to-low temperature ash" at temperatures ranging from 350℃ to 550℃.

6.In recent years, box-type carbonization furnaces capable of producing medium-to-high temperature charcoal (600℃ to 850℃) have also been developed.

7.The high calorific value of the smoke oil generated by box-type carbonization furnaces contributes to savings in drying costs and environmental protection expenses.

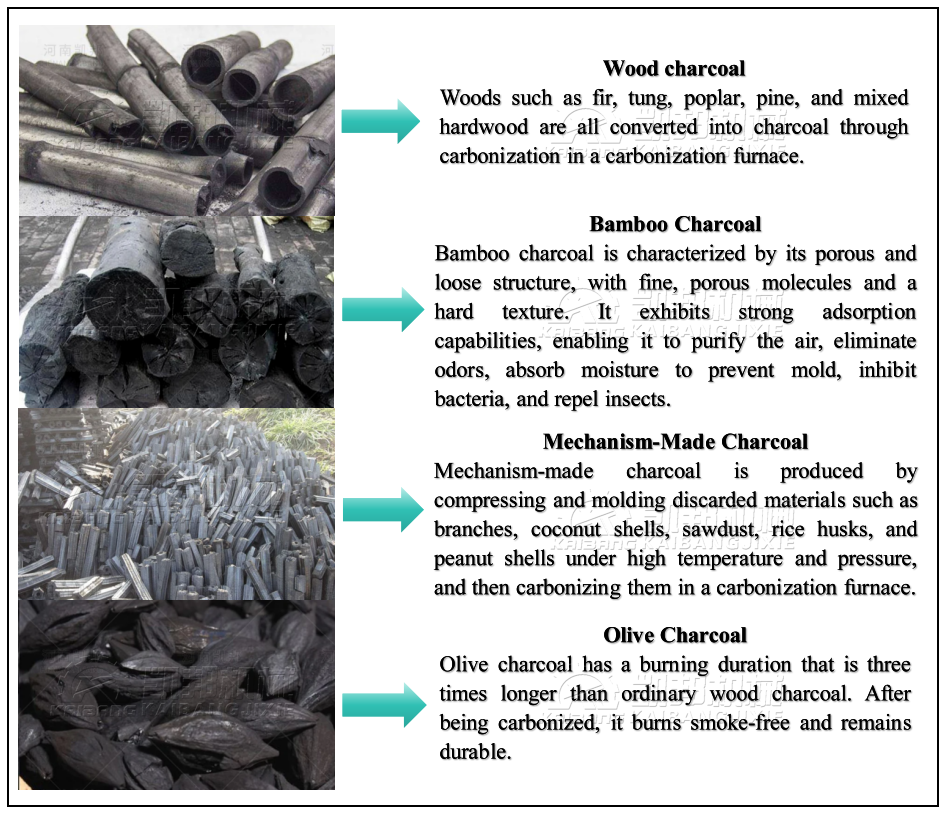

Adaptable to multiple materials

Carbonization of Various Wooden Materials

Carbonization of Various Wooden Materials

We are capable of carbonizing raw wood and mechanism-made charcoal, achieving high yield rates and excellent quality.

Our box carbonization furnace can be customized according to customer needs.

Henan Kaibang Machinery Manufacturing Co., Ltd. mainly produces: crushing equipment, drying equipment, forming equipment, pyrolysis reactor equipment, environmental protection equipment, and other complete production line equipment. The company's equipment production, casting and forming, mechanical processing, physical and chemical treatment, to assembly into machines, is fully tracked and inspected by quality testing engineers throughout the process to ensure that users receive high-quality, reliable equipment.

The company has been working hard to build the Kaibang brand for decades, always pursuing excellence, with high-quality staff, strict quality assurance system and perfect after-sales service. We warmly welcome domestic and overseas customers to visit our company for on-site inspection and guidance.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: info@kaibangmachinery.com

Phone: 15638129993

E-mail: +86 15638129993

Whatsapp:86 15638129993

Add: 800 meters east of the intersection of Chuangye Avenue and E23 in Gongyi Industrial Agglomeration Zone, Zhengzhou City, Henan Province, north of the road