Shisha Charcoal Packing Machine

Brand:KAIBANG

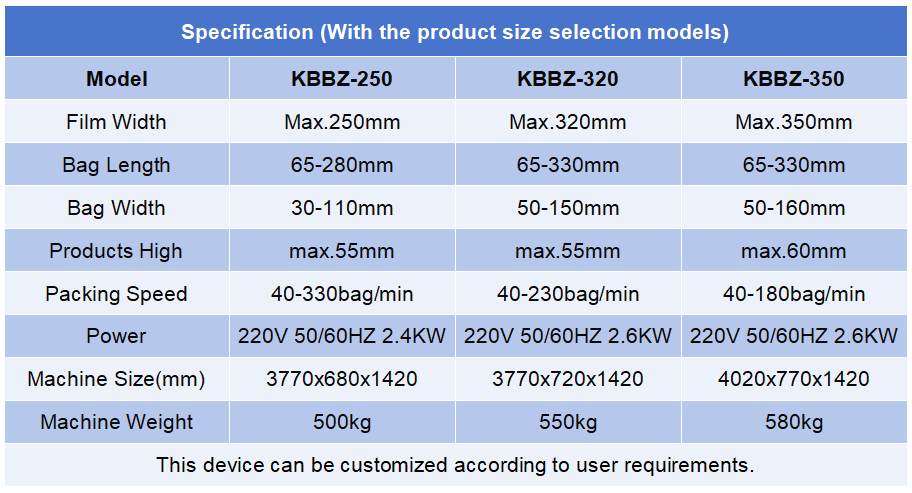

Model:KBBZ-320

Packing speed:40-230bag/min

Packing length:65-330mm

Bag width:50-150mm

Voltage:220V 50/60HZ 2.6KW

Size(mm):3770x720x1420

Weight:500kg

The shisha charcoal packaging machine is automated equipment designed for packing shisha charcoal products. Capable of handling various shapes and sizes, this machine integrates automatic feeding, metering, and sealing functions. With high-efficiency packaging and precise control capabilities, it significantly increases productivity while ensuring consistent product quality and aesthetic presentation.

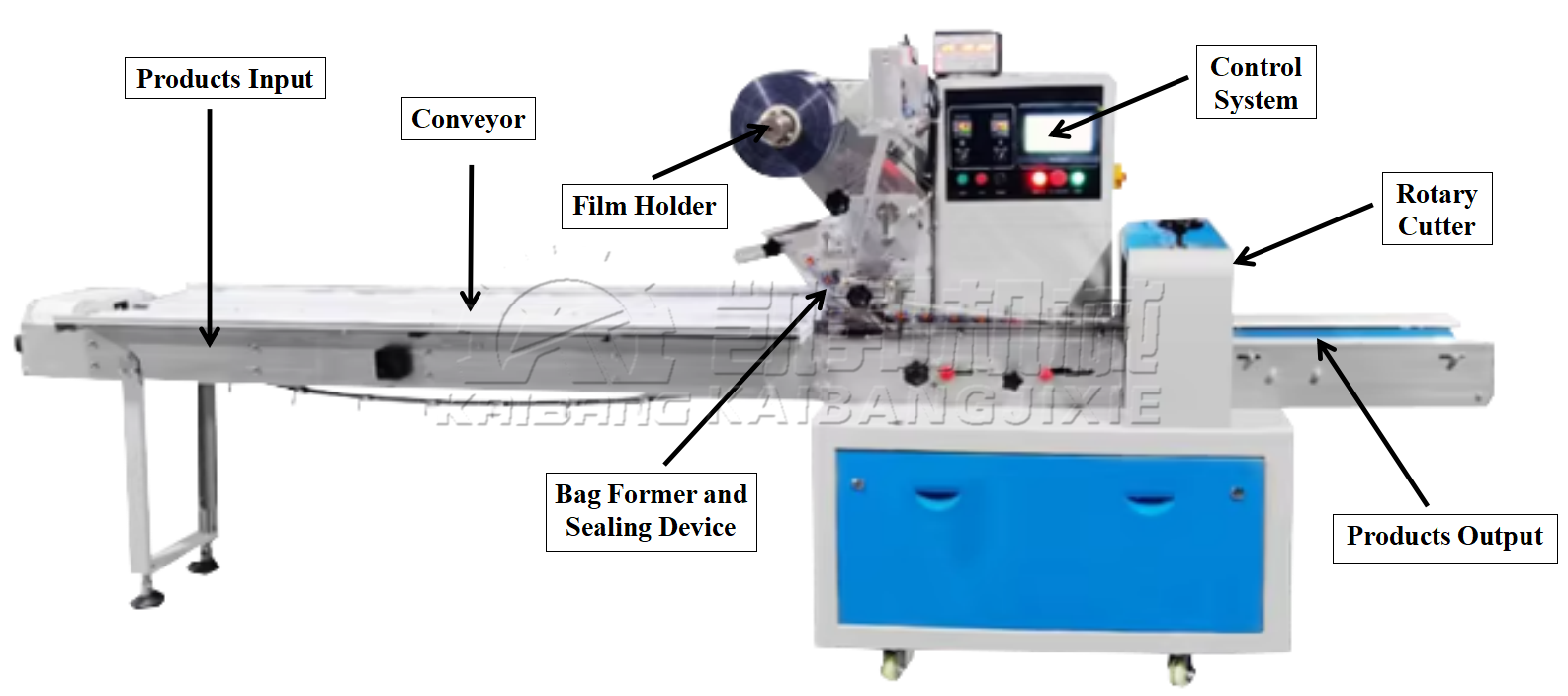

Feeding System: This component integrates hoppers/conveyor belts to deliver shisha charcoal/tobacco into the packaging workflow.

Weighing System: Employing precision sensors, this system ensures accurate dispensing (±0.5g tolerance) for each package.

Filling Mechanism: Utilizes pneumatic actuators to transfer metered materials into various packaging formats (bags, pouches, etc.).

Packaging Material Dispenser: Automatically feeds packaging materials while adapting to different types (PET/foil/paper) through modular design.

Sealing System: Features adjustable heat-sealing parameters to ensure airtight closure (IP65 rated) for product integrity.

Control Interface: The HMI provides real-time diagnostics and parameter adjustment via touchscreen, supporting multi-language operation.

Our shisha charcoal packaging machine accommodates both round and square charcoal products.

The Kaibang shisha charcoal packaging machine—specifically engineered for this application—is a high-efficiency system that automates, streamlines, and precisionizes the packaging process, offering significant benefits across various operational scenarios:

Shisha charcoal production plant

Seamlessly integrated into high-volume production lines, the machine enables fully automated packaging to meet mass production demands while increasing throughput efficiency by up to 40% compared to manual operations.

Packaging plants and processing centers

Serving packaging plants and processing centers, the equipment provides flexible packaging solutions for third-party manufacturers. Its adjustable settings accommodate over 30 standard bag sizes, making it ideal for businesses requiring quick format changes between different clients' specifications.

Export and international market

For exporters and international manufacturers, the machine ensures packaging consistency and professional standards compliance. It meets over 15 international packaging regulations (including EU IPPC-15 requirements) through adjustable sealing parameters and multi-language interface options.

Human-machine interface: Convenient and quick parameter settings. Fault self-diagnosis function, mechanical faults are clear at a glance.

Hot press sealing: Hot press sealing with independent PID control, ensuring tight and effective sealing.

Chain roller film: Coordinated lamination to accommodate various packaging materials, making the film roll smoother.

Product conveyor: Made of 304 stainless steel panels, ensuring food and drug safety, environmental hygiene, and accurate, stable feeding.

Electronic thermostat: Can control the use of plastic film tapes of different shapes in various packaging lines without controlling the sealing length.

In wood and charcoal machinery, we take pride in the meticulous design behind our water pipe charcoal packaging machine.

Key features include:

PLC intelligent control system: making operation simple and real-time adjustments possible.

Servo motor system: ensuring accurate and efficient execution of packaging tasks.

Independent temperature PID control: suitable for various packaging materials, maintaining freshness.

User-friendly interface: intuitive controls make your packaging process effortless.

<Note: With continuous technological upgrades, all parameters are provided for reference only. In case of any modifications, please refer to the actual product for accuracy.>

Henan Kaibang Machinery Manufacturing Co., Ltd. mainly produces: crushing equipment, drying equipment, forming equipment, pyrolysis reactor equipment, environmental protection equipment, and other complete production line equipment. The company's equipment production, casting and forming, mechanical processing, physical and chemical treatment, to assembly into machines, is fully tracked and inspected by quality testing engineers throughout the process to ensure that users receive high-quality, reliable equipment.

The company has been working hard to build the Kaibang brand for decades, always pursuing excellence, with high-quality staff, strict quality assurance system and perfect after-sales service. We warmly welcome domestic and overseas customers to visit our company for on-site inspection and guidance.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: info@kaibangmachinery.com

Phone: 15638129993

E-mail: +86 15638129993

Whatsapp:86 15638129993

Add: 800 meters east of the intersection of Chuangye Avenue and E23 in Gongyi Industrial Agglomeration Zone, Zhengzhou City, Henan Province, north of the road