Spray Tower

Brand:KAIBANG

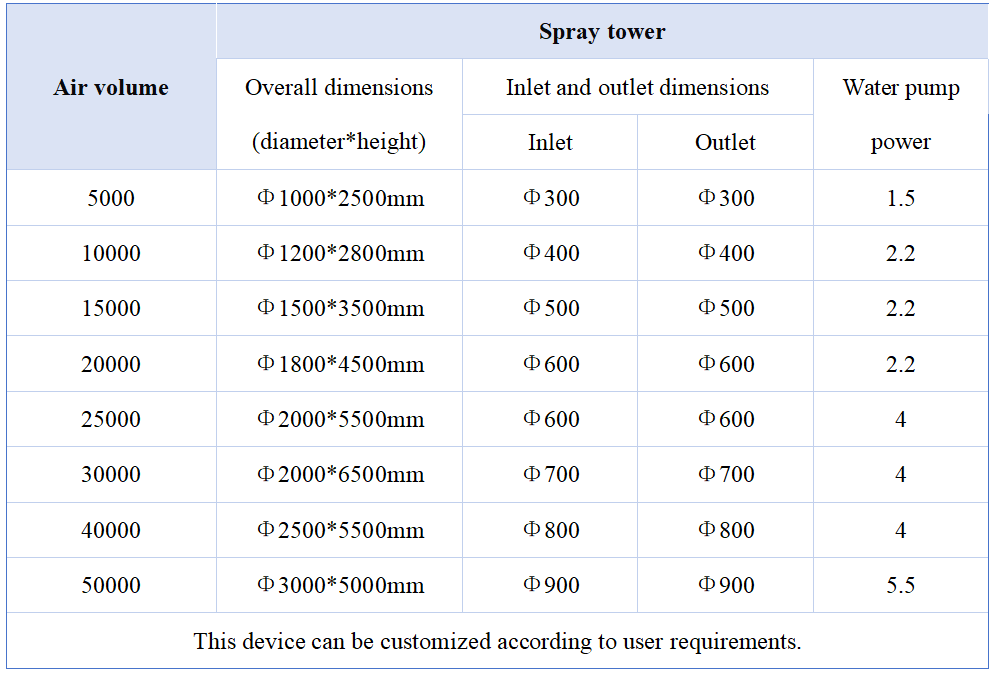

Size: full size or customized

Application: waste gas treatment in activated carbon plant, chemicals and other fields.

The spray tower, also known as a wet scrubber or wet dust collector, is an important activated carbon production equipment in an activated carbon plant. The spray tower uses water to contact the dust-laden gas and separates the dust from the gas by washing.It is used to capture coarse dust particles larger than 10 to 15 microns and is used for cooling and conditioning. The specific liquid consumption is low - only 0.5 to 8 liters per cubic meter of clean air. It can effectively remove odors, sulfur compounds, phenol, formaldehyde and other impurities.

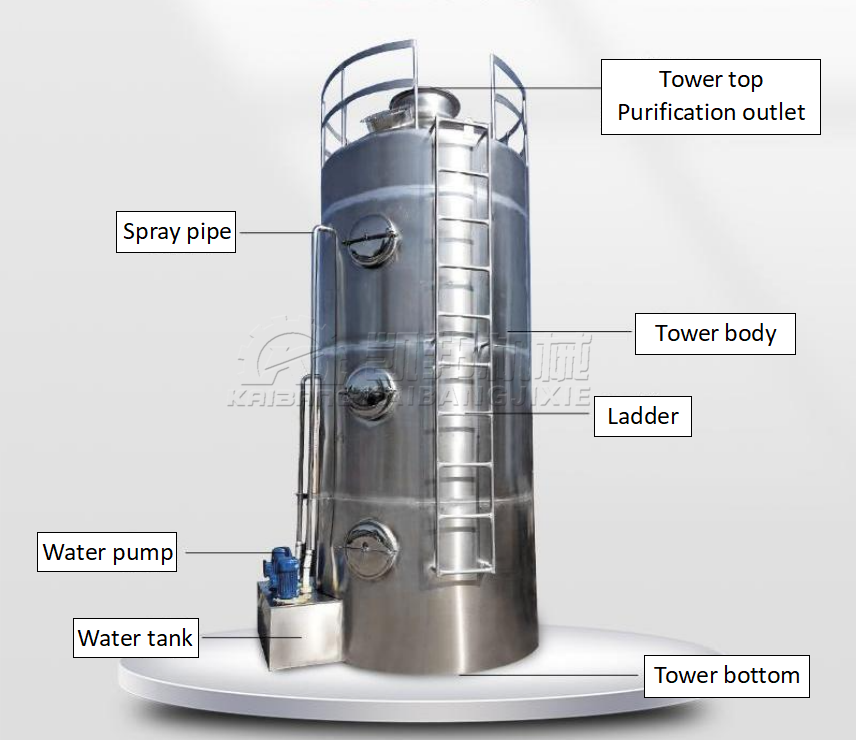

The design of the spray tower scrubber features a cylindrical vessel with inlet and outlet pipes for air flow and nozzles or sprayers for distributing the liquid. One or more layers of nozzles are located in the upper portion of the housing to spray the scrubbing liquid. The scrubbing liquid has a droplet size of 0.025 to 0.04 inches and effectively flushes the gas being cleaned, which moves in a countercurrent flow (from bottom to top) at a velocity of 2.3 to 5 ft/sec. At higher velocities, moisture entrainment occurs and dust is deposited on the inner surface of the scrubber outlet pipe.

The design of the spray tower scrubber features a cylindrical vessel with inlet and outlet pipes for air flow and nozzles or sprayers for distributing the liquid. One or more layers of nozzles are located in the upper portion of the housing to spray the scrubbing liquid. The liquid has a droplet size of 0.025 – 0.04 inches and effectively flushes the gas being cleaned, which moves in a countercurrent flow (from bottom to top) at a velocity of 2.3 – 5 ft/sec. At higher velocities, moisture entrainment occurs and dust is deposited on the inner surface of the scrubber outlet pipe.

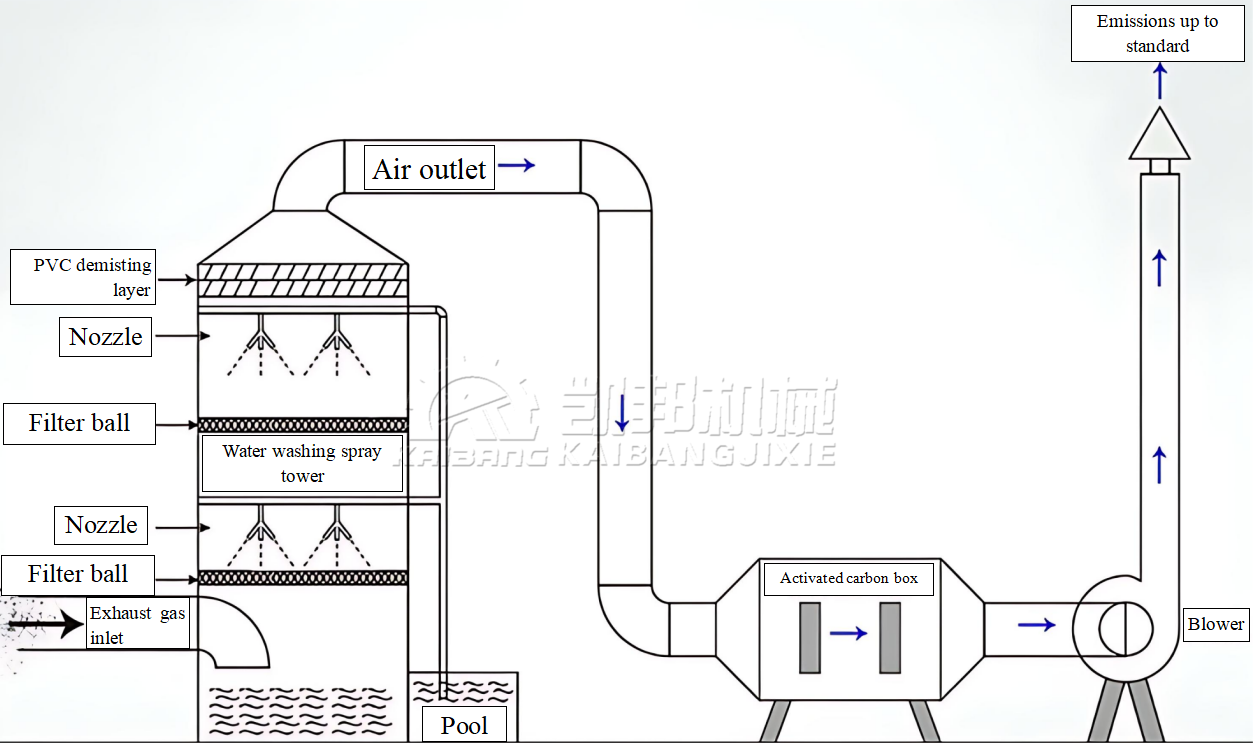

The exhaust gas is introduced into the purification tower by the wind pipe. Through the packing layer, theexhaust gas and the absorption lquld are tully exposed to the absorption and neutrallzation reaction ot the gasliquid two phase. After the exhaust gas is purified, the fan is discharged into the atmosphere by the dehydrationof the mist removal plate and the mist eliminator, The absorption liquid is pressurized by the pump at the bottomof the tower and then sprayed down at the top of the tower. Finally, it is recycled to the bottom of the tower forrecycling. The purified acid mist exhaust gas is lower than the national emission standard.

The process and product have the characteristics of simple structure, low energy consumption, high purification efficiency and wide application range. They can effectively remove water-soluble gases such as hydrogen chloride gas (HCl), hydrogen fluoride gas (HF), ammonia (NH3), sulfuric acid mist (H2SO4), chromic acid mist (CrO3), hydrocyanic acid gas (HCN), alkali vapor (NaOH), hydrogen sulfide gas (H2S), and formalin (HCHO). The acid mist waste gas is introduced into the purification tower through the air duct. After passing through the packing layer, the waste gas and the sodium hydroxide absorption liquid undergo a gas-liquid two-phase full contact absorption and neutralization reaction. After purification, the acid mist waste gas is dehydrated and defogged by the demister plate and then discharged into the atmosphere by the fan. The absorption liquid is pressurized by a water pump at the bottom of the tower and sprayed down at the top of the tower, and finally refluxed to the bottom of the tower for recycling. The purified acid mist waste gas meets the emission requirements of the Guangdong Provincial Local Emission Standard, which is lower than the national emission standard.

1.The spray tower occupies a small area, is easy to maintain, and has low operating costs.

2.It has high purification efficiency and can meet the gas use environment under different conditions.

3.It is corrosion-resistant and can resist weathering.

4.It has stable performance and high purification efficiency.

5.It is light in weight and easy to install, transport and maintain.

6.It is especially suitable for water-soluble dusty gases.

7.The internal spray is uniform, providing a large gas-liquid contact area, etc.

8.The equipment has low operating resistance, and the equipment operation status can be monitored in time through instruments.

<Note: With continuous technological upgrades, all parameters are provided for reference only. In case of any modifications, please refer to the actual product for accuracy. >

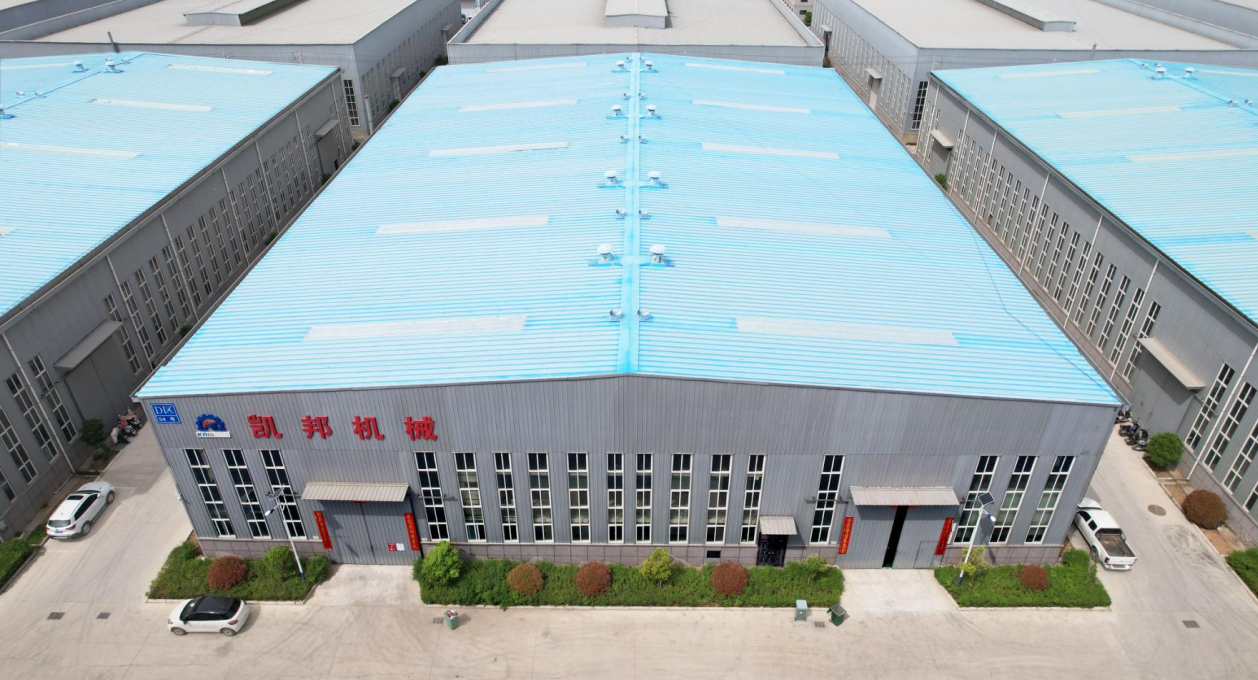

Henan Kaibang Machinery Manufacturing Co., Ltd. mainly produces: crushing equipment, drying equipment, forming equipment, pyrolysis reactor equipment, environmental protection equipment, and other complete production line equipment. The company's equipment production, casting and forming, mechanical processing, physical and chemical treatment, to assembly into machines, is fully tracked and inspected by quality testing engineers throughout the process to ensure that users receive high-quality, reliable equipment.

The company has been working hard to build the Kaibang brand for decades, always pursuing excellence, with high-quality staff, strict quality assurance system and perfect after-sales service. We warmly welcome domestic and overseas customers to visit our company for on-site inspection and guidance.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: info@kaibangmachinery.com

Phone: 15638129993

E-mail: +86 15638129993

Whatsapp:86 15638129993

Add: 800 meters east of the intersection of Chuangye Avenue and E23 in Gongyi Industrial Agglomeration Zone, Zhengzhou City, Henan Province, north of the road