Sawdust Briquette Machine

Sawdust Briquette Machine

Brand: KAIBANG

Capacity:260-360kg/h (The output varies according to the pressing density and raw materials.)

Heating Temperature: Around 350°C

Suitable Raw Materials:wood chips, bamboo chips, peanut shells, rice husks, etc.

The briquetting machine processes particulate waste materials, such as bamboo, wood, fruit shells, and straw (excluding rice straw and wheat straw), with a moisture content below 12% and particle sizes under 5mm in length and 3mm in diameter, without adding any binders. Under high temperature and pressure, it produces porous, stick-shaped solid fuel briquettes, typically in square or hexagonal shapes.

The products have the characteristics of high density, small volume and good combustibility, which can replace firewood and coal.

Equipped with a fully automatic electronic control system, the molding temperature can be easily adjusted, providing a clear view of the equipment's operating status.

No binder or noxious chemical need to use.

The humidity of the raw materials is controlled in 8-12%.

Using the advanced Hot air drying system with the perfect performance.

After the processing of High temperature, purification, smoke removing, the carbonizing equipment transforms the semi-finished bio-fuel briquette into a smoke-free, tasteless, non-toxic cleaning carbon.

The Sawdust Briquette Machine boasts a reasonable design, reliable quality, a simple structure, comprehensive functionality, labor-saving characteristics, and strong applicability, making it capable of easily forming sticks from various materials.

The spiral conveyor of the sawdust briquette machine is made of high-quality 35cr steel and undergoes heat treatment, resulting in high hardness, toughness, and excellent wear resistance.

The sawdust briquette machine is powered by a 18.5-22kw electric motor (most on the market use 11kw motors, which result in low molding efficiency and are prone to burnout due to overload). This ensures the stability of the equipment, and our company guarantees that we will never compromise user interests to reduce costs.

The charcoal machine with stick-forming capability may lack a fancy appearance, but it possesses high-quality equipment. Many manufacturers frequently change the shells of their stick-forming machines and claim them to be new models, severely deceiving consumers.

The sawdust briquette machine is equipped with three bearings (while other manufacturers only provide two), which increases the machine's stability and durability.

The head of the sawdust briquette machine weighs approximately 180kg (compared to 110kg on the market), and we guarantee no corners were cut. Users can measure it themselves when visiting our factory.

It uses a large screw to compress and extrude the biomass into briquettes. The natural lignin content in biomass is liberated with wood fiber under high pressure and temperature.

In the briquetting process lignin serves as the glue and combines the particles of wood together,thus binding, compressing the biomass to form into various molds of high density briquette, such as hexagonal, quadrangular, square,etc.

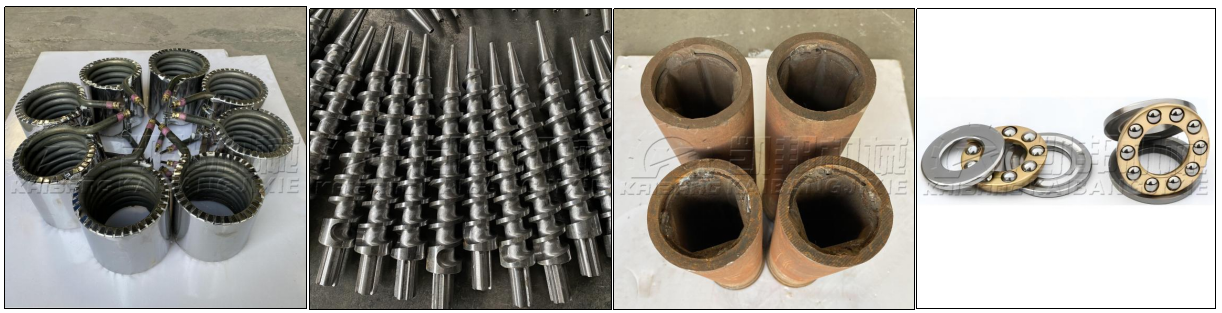

Heating ring

The heating ring is made of thick copper wire and the inside is ceramic.

Screw propeller

It is made from special 35Cr high-quality steel and has the advantages of wear resistance, high pressure resistance, and high abrasion resistance. The special wear-resistant material has a lifespan more than ten times longer than that of traditional thrusters.

Forming Barrel

1.It can create different shapes for the final wood briquettes.

2.Constructed from a high-wear-resistant steel composite, it exhibits high toughness and hardness.

Bearings

Equipped with bearings from a reputable manufacturer in Wafangdian, the machine features three bearings, guaranteeing a service life of more than five years, thus enhancing its stability and durability.

Raw material

Sawdust Briquette Machine applies for various biomass material, such as rice shell, begass, sawdust, walnut shell, peanut shells, wood shavings, coconut shell power, bamboo powder, corn cob, fungus, husk, cotton shell etc.

Final Product

This bio-fuel briquette is 45-80mm in diameter, occurs in the hollow quadrangular or hexagonal cylinder or hollow hexagonal with a 15-20mm hole through the body.

Optional shapes: square, hexagon, pentagon, pentagon with sides, hexagon with sides, circle.

The optional diameter includes: 46-48-50 mm, 60 mm, 70 mm, 80 mm, etc.

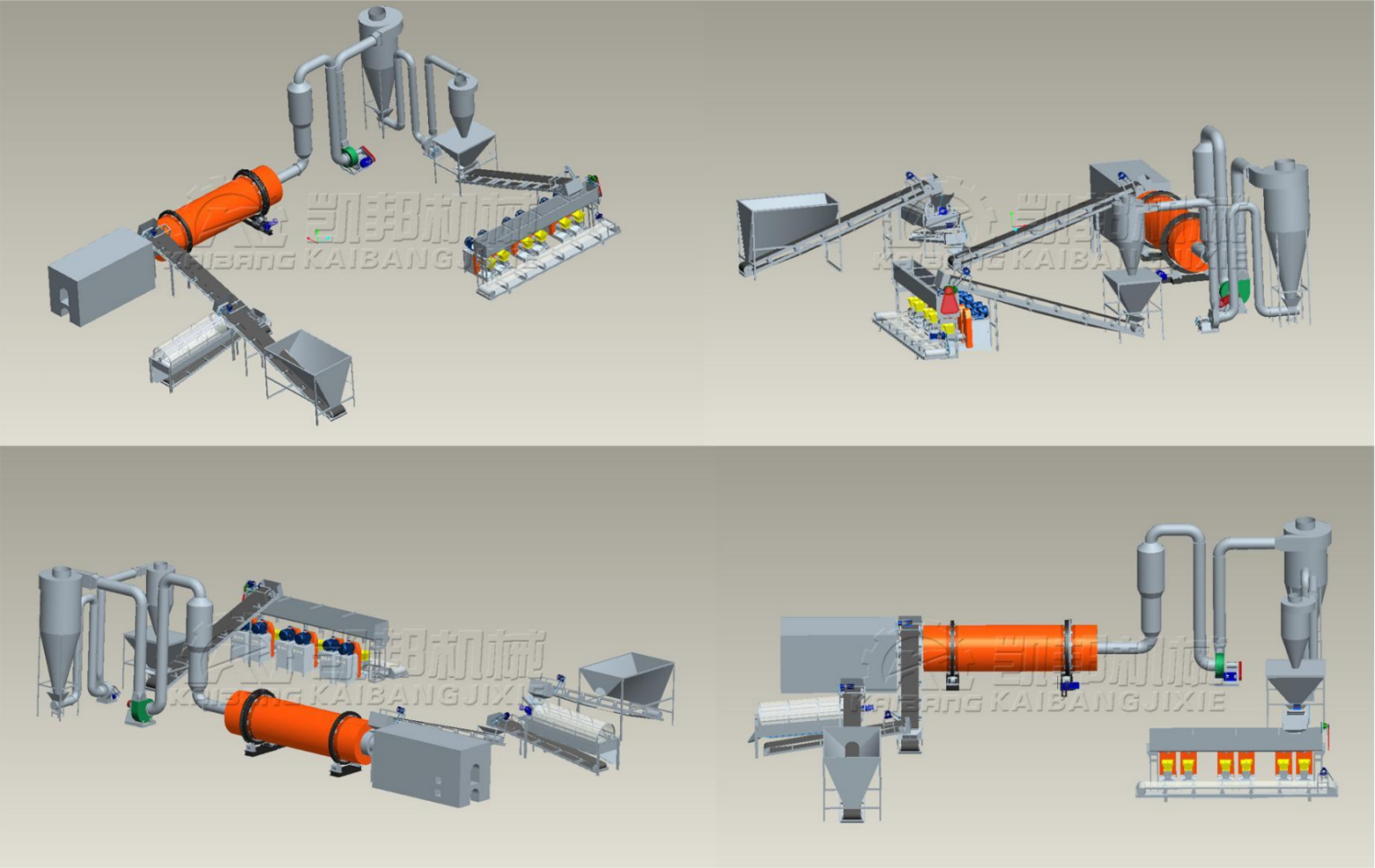

The biomass briquette machine is an indispensable machine in the production of mechanical charcoal production line. It first crushes bamboo chips, sawdust, peanut shells, corn cores and other raw materials into particles less than 6mm through wood chip crusher, then dries them through dryer, and sends these particles into the rod making machine for rod making.

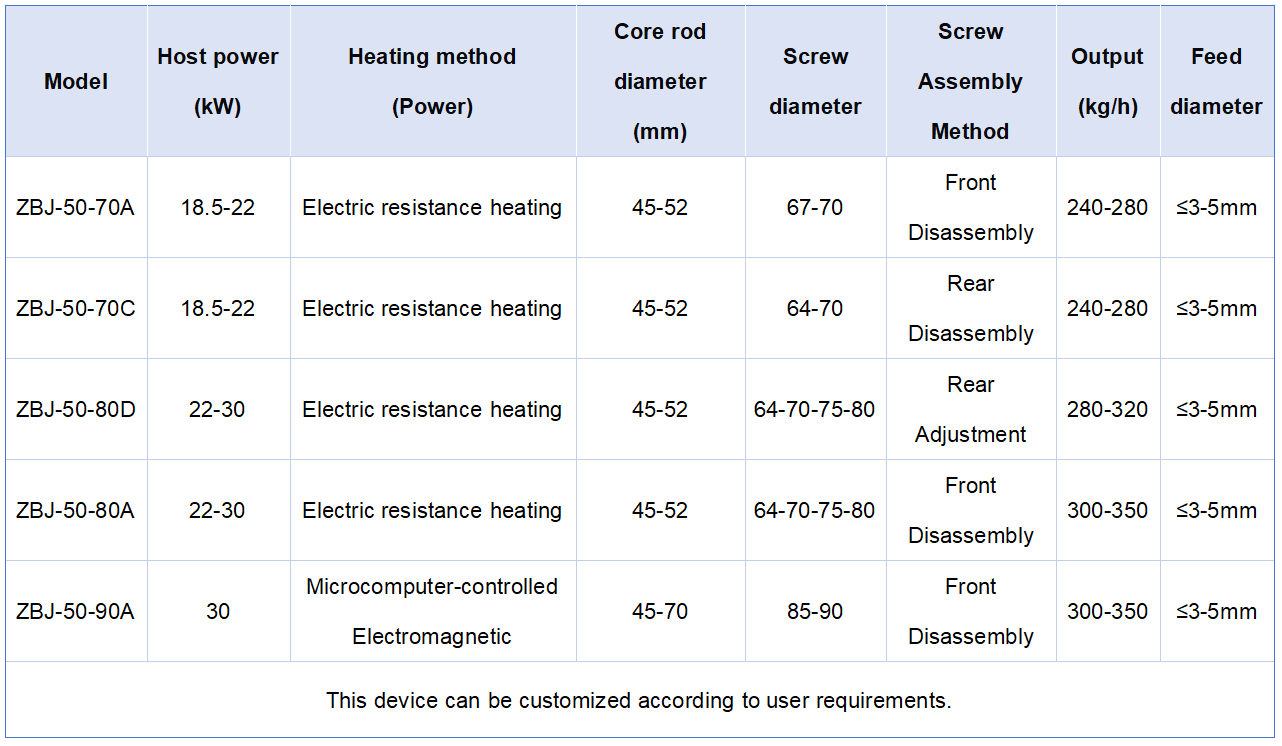

<Note: With continuous technological upgrades, all parameters are provided for reference only. In case of any modifications, please refer to the actual product for accuracy. >

Henan Kaibang Machinery Manufacturing Co., Ltd. mainly produces: crushing equipment, drying equipment, forming equipment, pyrolysis reactor equipment, environmental protection equipment, and other complete production line equipment. The company's equipment production, casting and forming, mechanical processing, physical and chemical treatment, to assembly into machines, is fully tracked and inspected by quality testing engineers throughout the process to ensure that users receive high-quality, reliable equipment.

The company has been working hard to build the Kaibang brand for decades, always pursuing excellence, with high-quality staff, strict quality assurance system and perfect after-sales service. We warmly welcome domestic and overseas customers to visit our company for on-site inspection and guidance.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: info@kaibangmachinery.com

Phone: 15638129993

E-mail: +86 15638129993

Whatsapp:86 15638129993

Add: 800 meters east of the intersection of Chuangye Avenue and E23 in Gongyi Industrial Agglomeration Zone, Zhengzhou City, Henan Province, north of the road