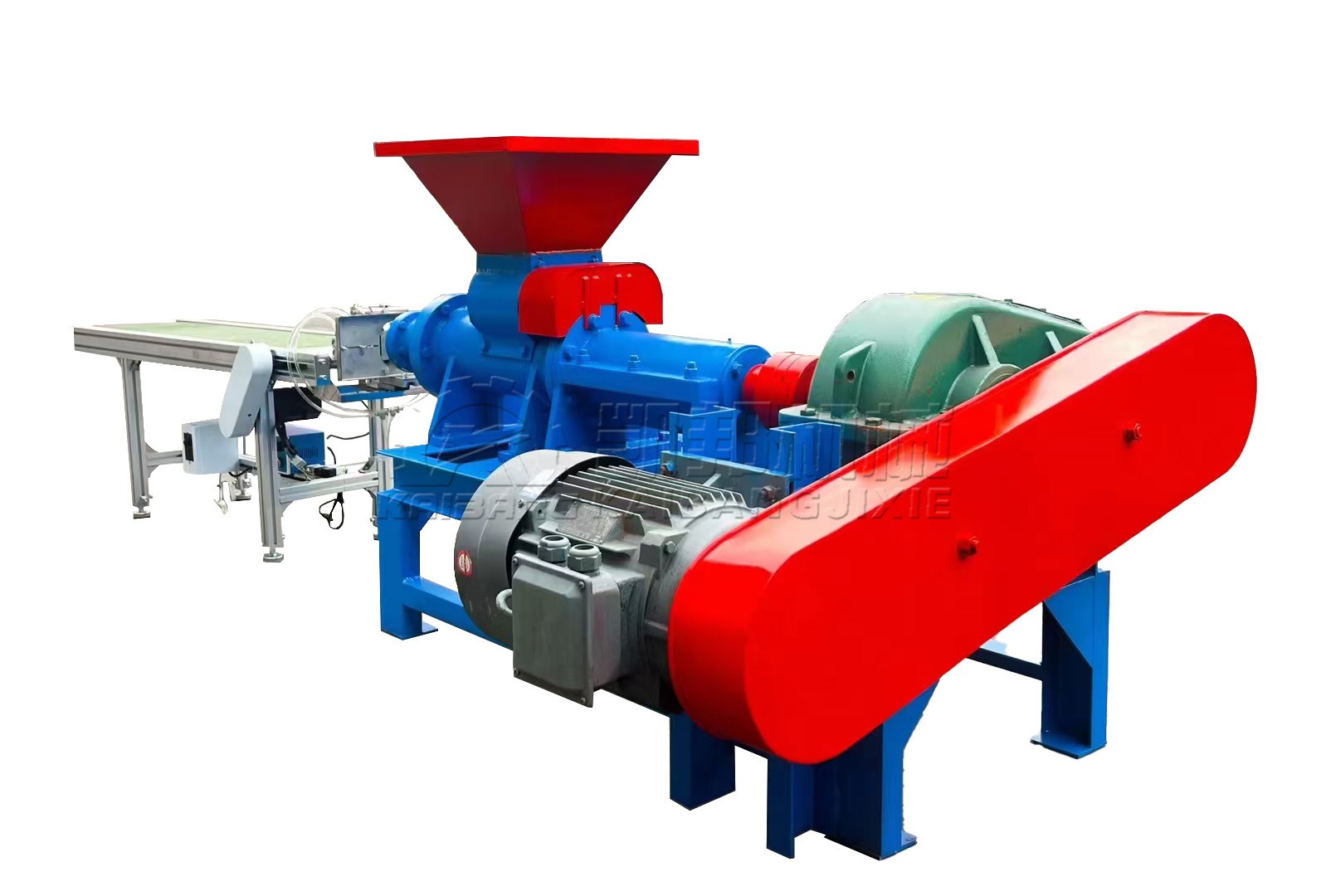

Charcoal Extrude Machine

Brand: KAIBANG

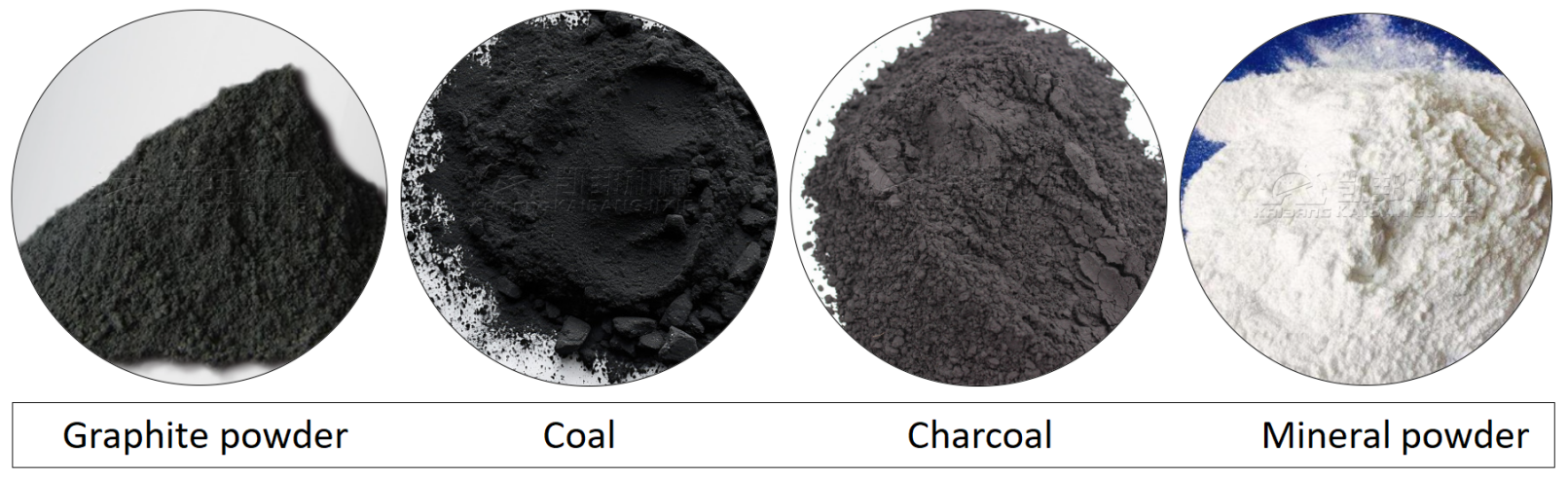

Applicable Materials Include: Coal Powder, Charcoal Powder, Iron Powder, Coke Powder, and Others.

Short Description:

Charcoal extruder machine, which using the principle of screw extrusion to compress the coal powder into a predetermined shape with a certain intensity.

After the coal powder poured into machine chamber,it bears tremendous pressure.With the help of all kinds of shaped molds,it will be shaped into certain shapes.

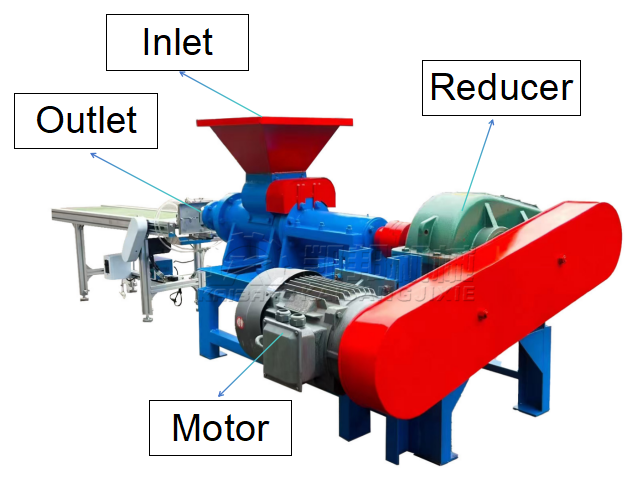

Charcoal extruder is a screw-type forming machine to produce rod shape briquettes from charcoal. As it also can be used for pressing coal, activated carbon, and semi-coke powder, it is also called a coal briquette machine. This machine has a compact design, including the electric motor , reduction box, feeding hopper, screw propelling part, discharging hole, machine base, etc.

The charcoal extruder machine adopts the principle of screw extrusion to compress the coal/charcoal powder into shaped briquettes. After the charcoal powder is poured into the feeding hopper, it is propelling forward to the discharging hole of the briquette machine by the screw. From the screw chamber to the mold, space is becoming smaller. Under the tremendous pressure, charcoal passes through the molds and finally form into certain shapes.

1. This charcoal briquette making machine can make coal and charcoal powder into different rod sticks of briquettes, such as square rod, round rod, hexagonal rod, flower rod, or other customized shapes.

2. The shape of the sticks can be made by customers’ requirements.

3. The final product made by this machine is no pollution or smoke.

4. Material required size: <3mm.

5. For the length, the automatic cutter is available.

1.The charcoal extrude machine is composed of a motor, a reducer, a screw propeller shaft, a mold, and the final cutter.

2.We provide customers with a large number of different molds to choose from, and we can also customize them according to customer needs.

3.This machine has a compact design, including the electric motor, reduction box, feeding hopper, screw propelling part, discharging hole, machine base, etc.

Almost all kinds of biomass material are available to this machine: sawdust, shavings, wood waste, branches, rice husks, peanut shells, bagasse, vinasse, cotton rods, corn rods, wheat straw, rice straw and other crops. And the raw material is first to be carbonized and then to pressed into carbon rods.

Besides the charcoal and coal, this extruding machine can also produce briquettes from coke, sludge, olive pomace, cow dung, etc. For making good quality briquettes, charcoal powder size must be less than 3mm, and moisture around 20%. To meet the requirements of different customers, mold shapes can be hexagonal, square, circular, etc. Moreover, customers can choose to produce hollow or solid briquettes and the briquette’s diameter range is 3-50mm.

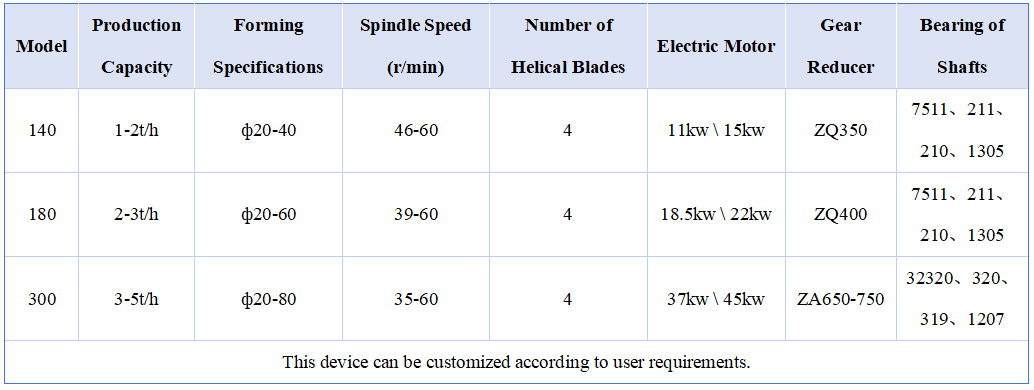

<Note: With continuous technological upgrades, all parameters are provided for reference only. In case of any modifications, please refer to the actual product for accuracy. >

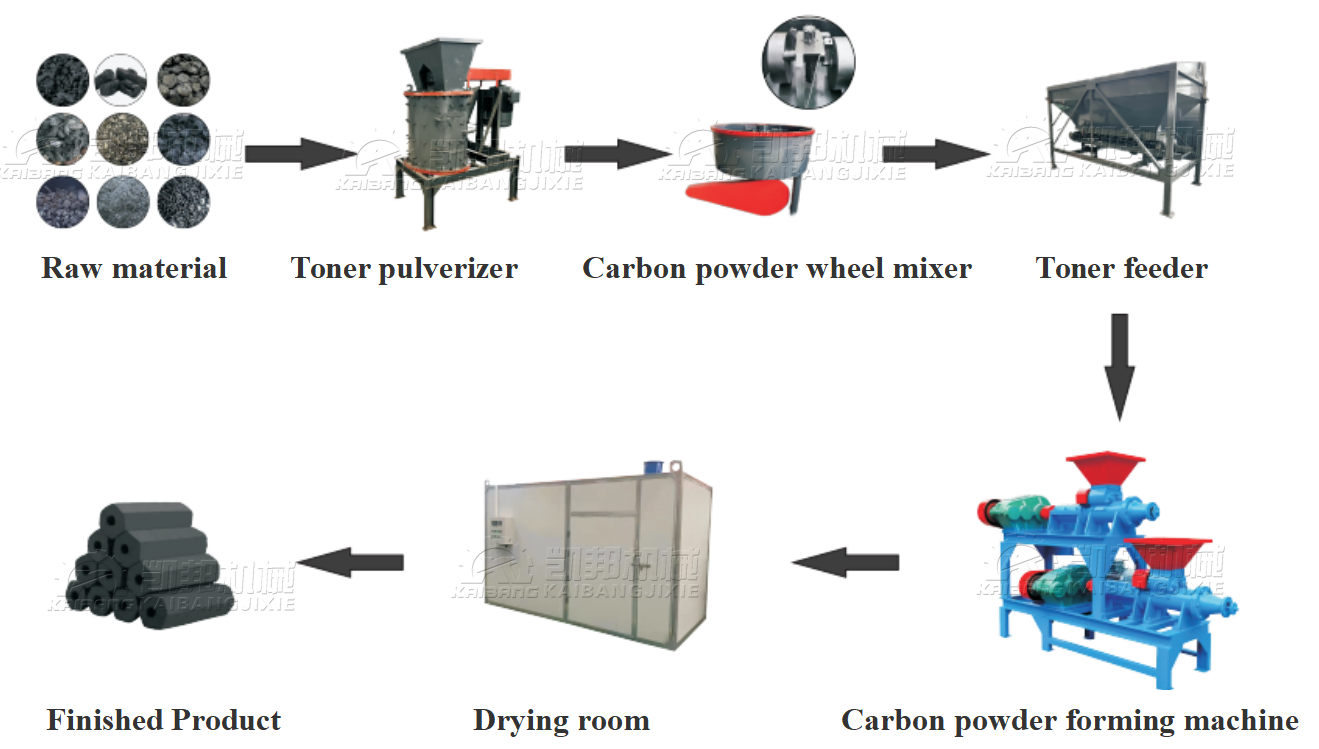

1. If the raw material is sawdust or rice husk or coconut shell.Use carbonization furnace to carbonize raw material into charcoal.

2. The second step:Use crusher to grind charcoal into powder.

3. Then use the Charcoal mixer to mix the charcoal powder with binder and water.

4. Use charcoal extruder machine to produce many different shapes briqette base on own need.

5. Dry the final products by dryer or naturally.

Henan Kaibang Machinery Manufacturing Co., Ltd. mainly produces: crushing equipment, drying equipment, forming equipment, pyrolysis reactor equipment, environmental protection equipment, and other complete production line equipment. The company's equipment production, casting and forming, mechanical processing, physical and chemical treatment, to assembly into machines, is fully tracked and inspected by quality testing engineers throughout the process to ensure that users receive high-quality, reliable equipment.

The company has been working hard to build the Kaibang brand for decades, always pursuing excellence, with high-quality staff, strict quality assurance system and perfect after-sales service. We warmly welcome domestic and overseas customers to visit our company for on-site inspection and guidance.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: info@kaibangmachinery.com

Phone: 15638129993

E-mail: +86 15638129993

Whatsapp:86 15638129993

Add: 800 meters east of the intersection of Chuangye Avenue and E23 in Gongyi Industrial Agglomeration Zone, Zhengzhou City, Henan Province, north of the road